A flooded air-cooled heat pump unit

An air-cooled heat pump and flooded technology, which is applied in the field of flooded air-cooled heat pump units, can solve the problems of reduced reliability of the unit, stuck valve core, and improper reversing, so as to prevent large fluctuations in water temperature and avoid stuck The effect of reducing the dead and defrosting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

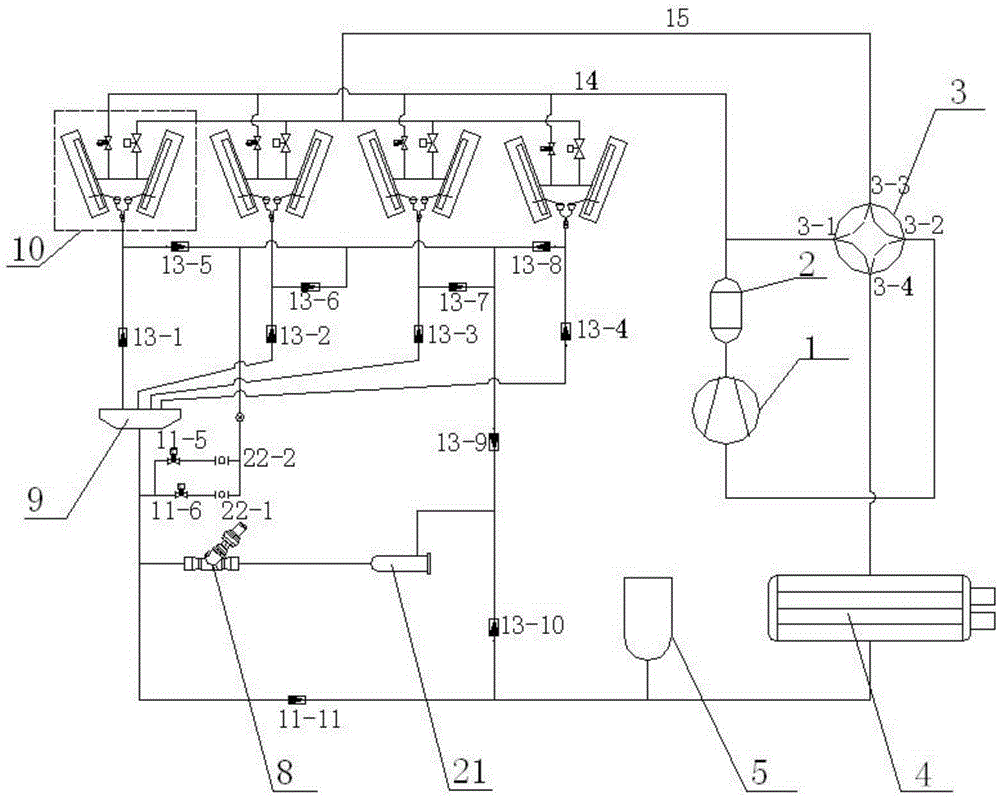

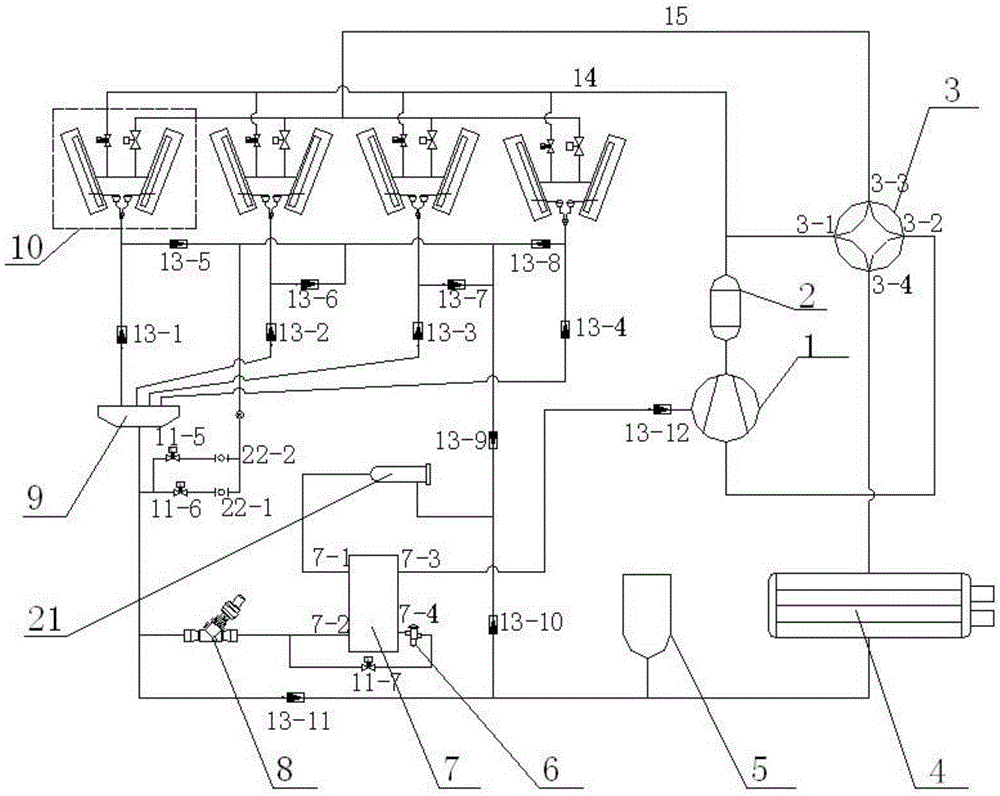

[0021] Example 1, such as figure 2 As shown, a flooded air-cooled heat pump unit includes a compressor 1, a flooded evaporator 4, an electric four-way valve 3, an expansion valve 6, a condensation coil unit 10, an external oil separator 2, a dry filter Device 21, economizer 7, main expansion valve 8, liquid reservoir 5, liquid separator 9.

[0022] The exhaust port of the compressor 1 is connected to the external oil separator 2, and the exhaust gas enters the external oil separator 2 for secondary oil separation to prevent excessive refrigeration oil from entering the system. The external oil separator 2 The outlet pipe is divided into two paths: the main exhaust pipe and the bypass defrosting pipe 14, the main exhaust pipe is connected to the first interface 3-1 of the electric four-way valve 3, and the second interface of the electric four-way valve 3 3-2 is connected to the suction port of the compressor 1, the third port 3-3 is connected to the coil unit, the fourth por...

Embodiment 2

[0028] Example 2, such as figure 1 As shown, there is no economizer 7 and corresponding pipeline parts. The outlet pipeline of the dry filter 21 is directly connected with the inlet of the main expansion valve 8 . The condensed high-pressure liquid does not go through the recooling process of the economizer 7 and directly enters the main expansion valve 8 to throttle and evaporate. Cooling, heating and defrosting are implemented in the same way as in method one. This embodiment is easy to understand for those skilled in the professional field, so it is not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com