Detection device of offshore platform hydraulic type elevating mechanism

A lifting mechanism and offshore platform technology, applied in the field of offshore platform lifting system testing, can solve the problems of difficult to meet accurate detection standards, low accuracy of ocean simulation, unstable detection accuracy, etc., to reduce detection cost, reduce detection difficulty, The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

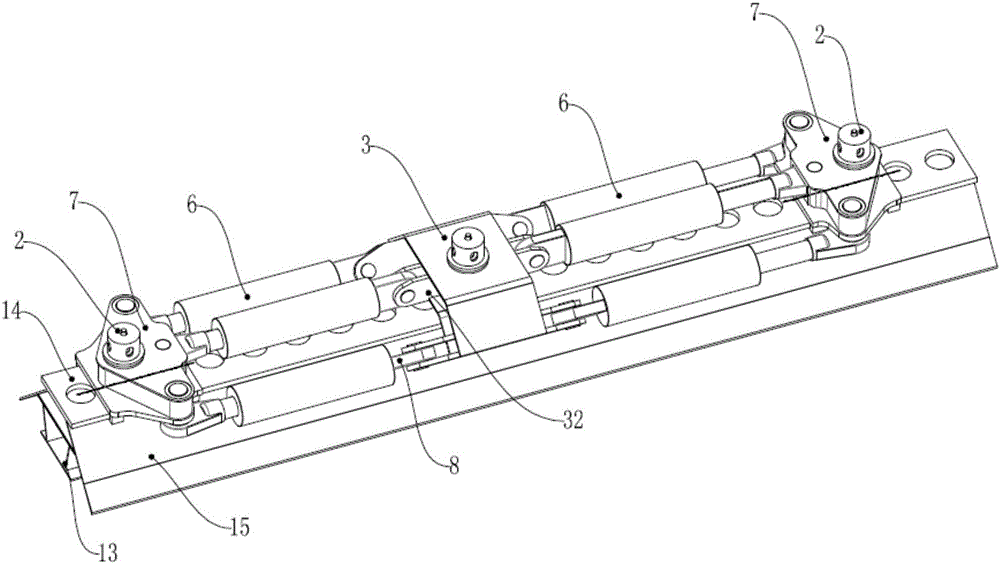

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

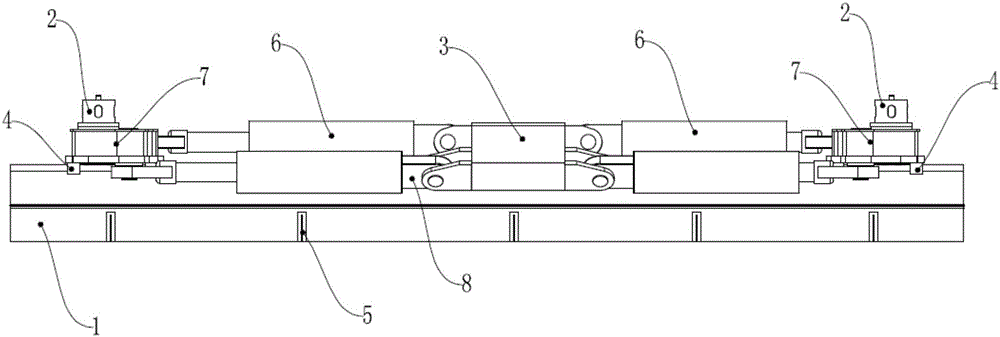

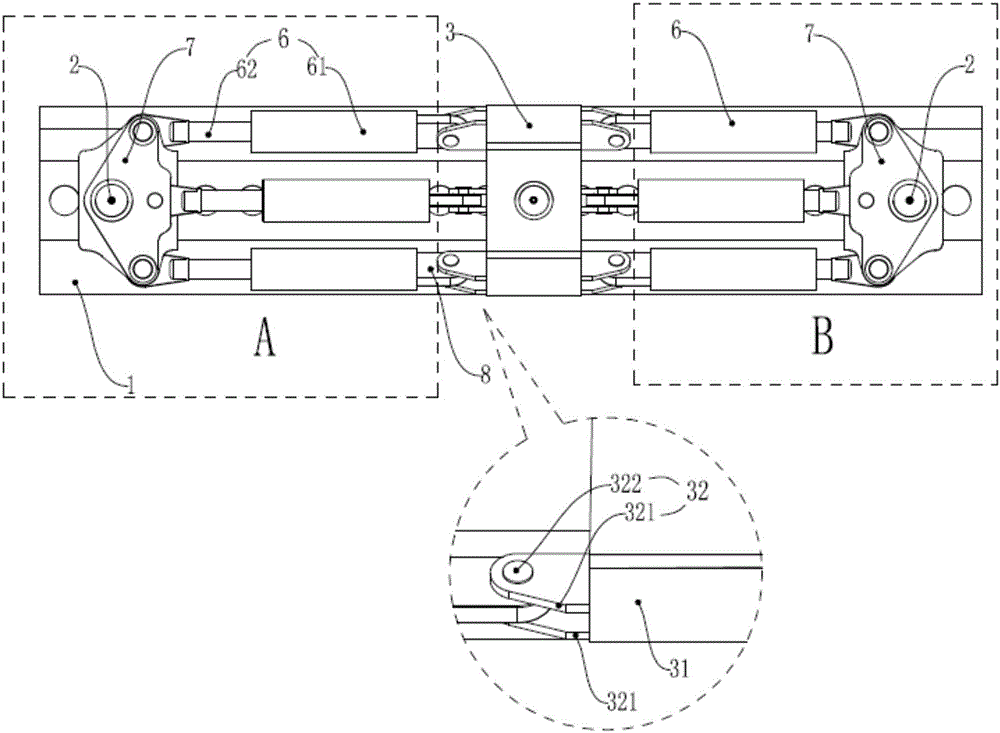

[0030] like figure 1 As shown, a detection device for a hydraulic lifting mechanism of an offshore platform includes a base 1, two lifting mechanisms to be tested and a connection box 3; the connection box 3 is arranged on the base 1 through a guide slide 4, And the base 1 is divided into a left lifting mechanism installation area A and a right lifting mechanism installation area B, such as figure 2 shown;

[0031] The left lifting mechanism installation area A and the right lifting mechanism installation area B are respectively equipped with two described lifting mechanisms to be tested, and the left lifting mechanism installation area A and the right lifting mechanism installation area B are all provided with a plurality of first pin holes 11. The base 1 is also provided with a second pin hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com