Damper device

A technology of vibration damping device and elastic body, which is applied in the direction of transmission device, fluid transmission device, spring/shock absorber functional characteristics, etc. It can solve the rigidity change of dual-channel shock absorber, the increase of torque converter weight, and the inability to attenuate vibration, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, modes for implementing the invention of the present disclosure will be described with reference to the drawings.

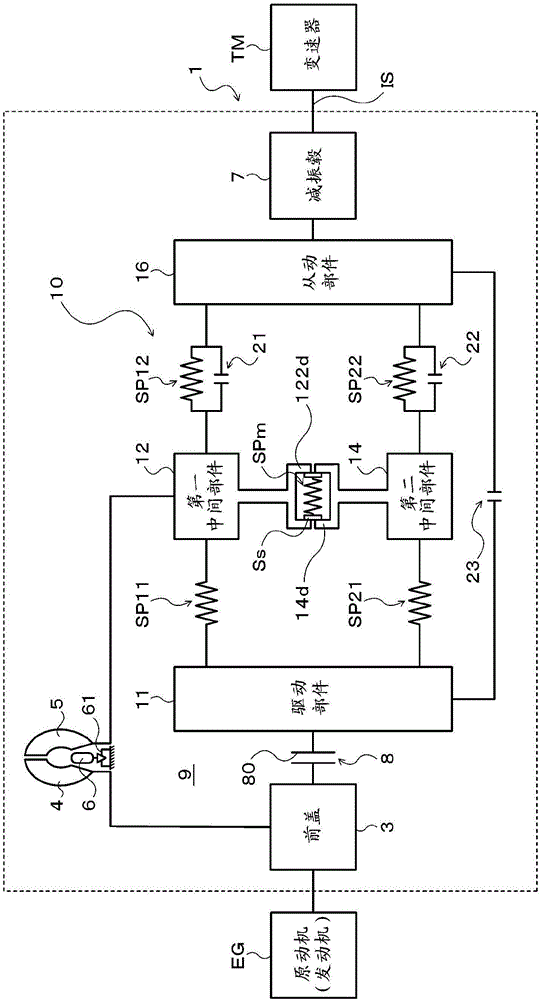

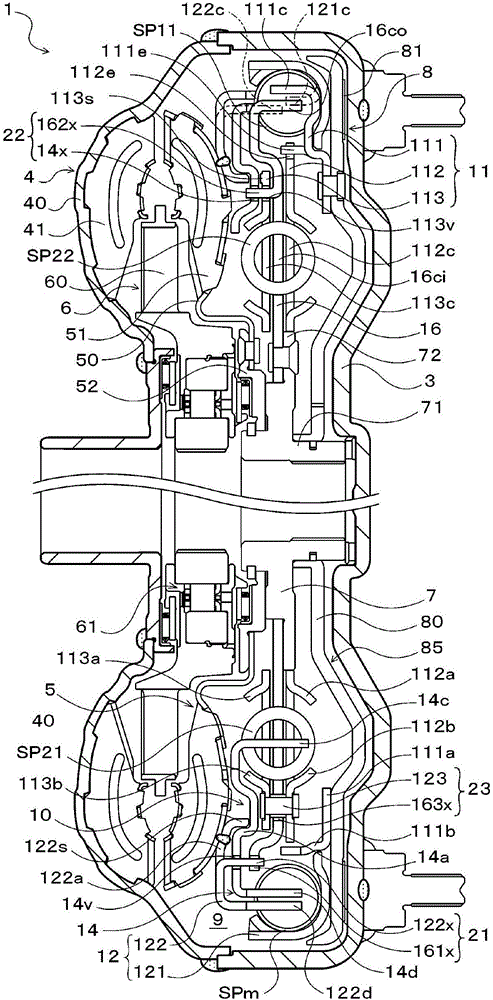

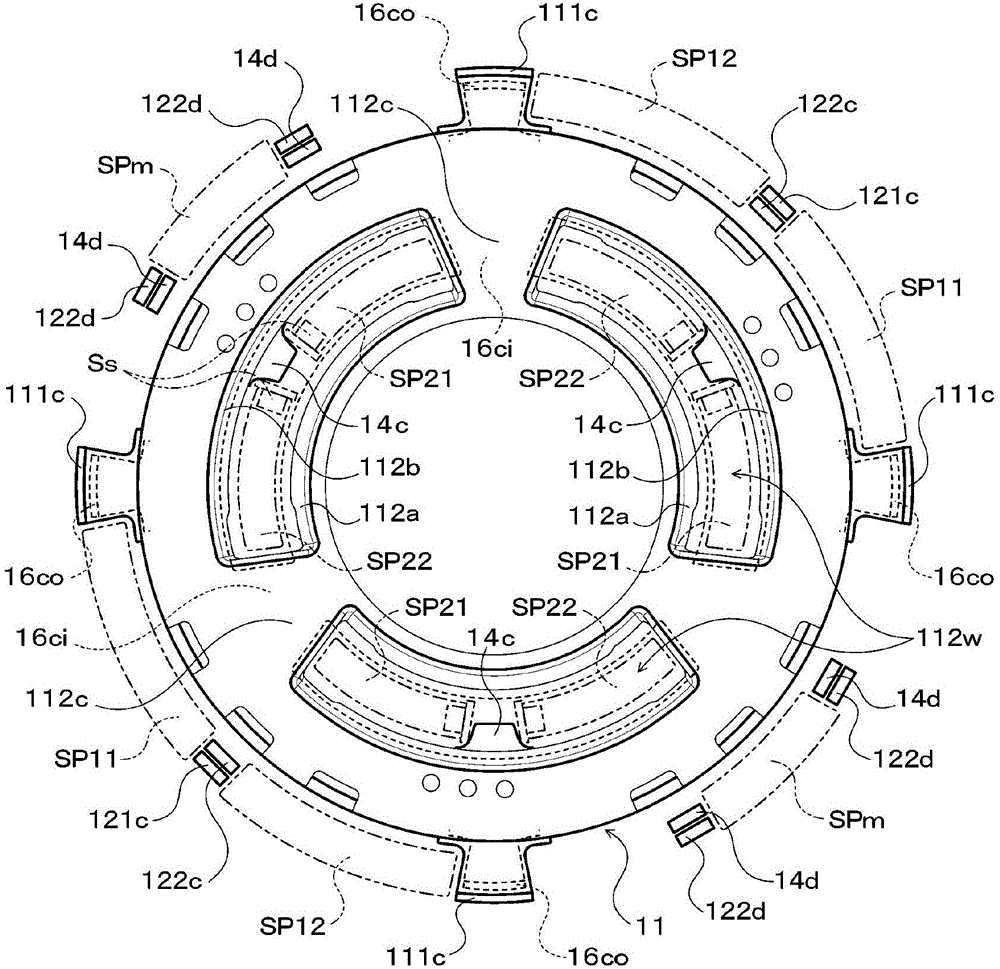

[0026] figure 1 is a schematic configuration diagram showing a starting device 1 including a vibration damping device 10 of the present disclosure, figure 2 It is a sectional view showing the starting device 1 . The starting device 1 shown in these drawings is mounted on a vehicle including an engine (in this embodiment, an internal combustion engine) EG as a prime mover, and includes a front cover connected to a crankshaft of the engine EG in addition to the vibration damper 10. 3. The pump wheel (input side fluid transmission member) 4 fixed to the front cover 3, the turbine wheel (output side fluid transmission member) 5 that can rotate coaxially with the pump wheel 4, is connected to the vibration damping device 10 and fixed to the motor as an automatic A transmission (AT), a continuously variable transmission (CVT), a dual clutch transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com