Automatic lifting broiler chicken roost

An automatic lifting and perching frame technology, which is applied in the field of poultry farming, can solve the problems of high incidence of leg diseases and achieve the effect of stable structure, tight chest and leg muscles, and increased quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

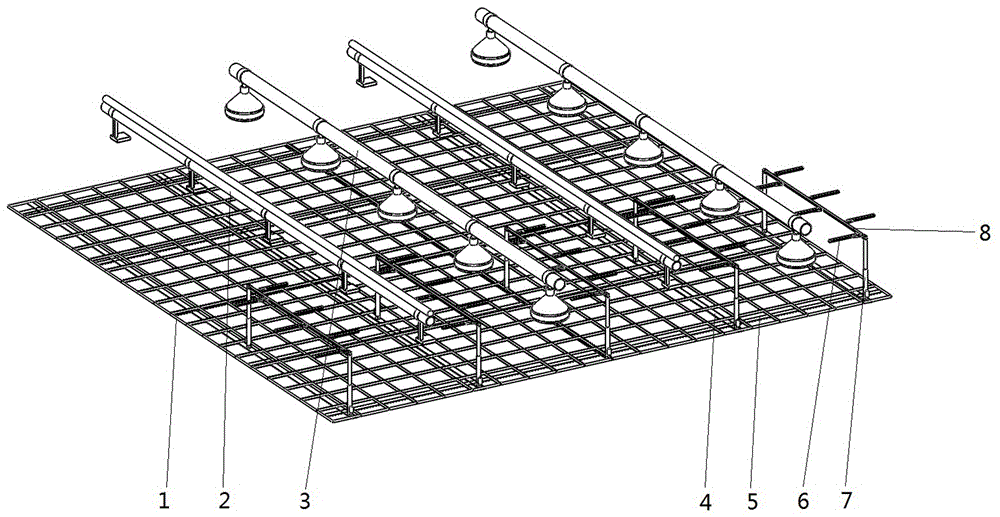

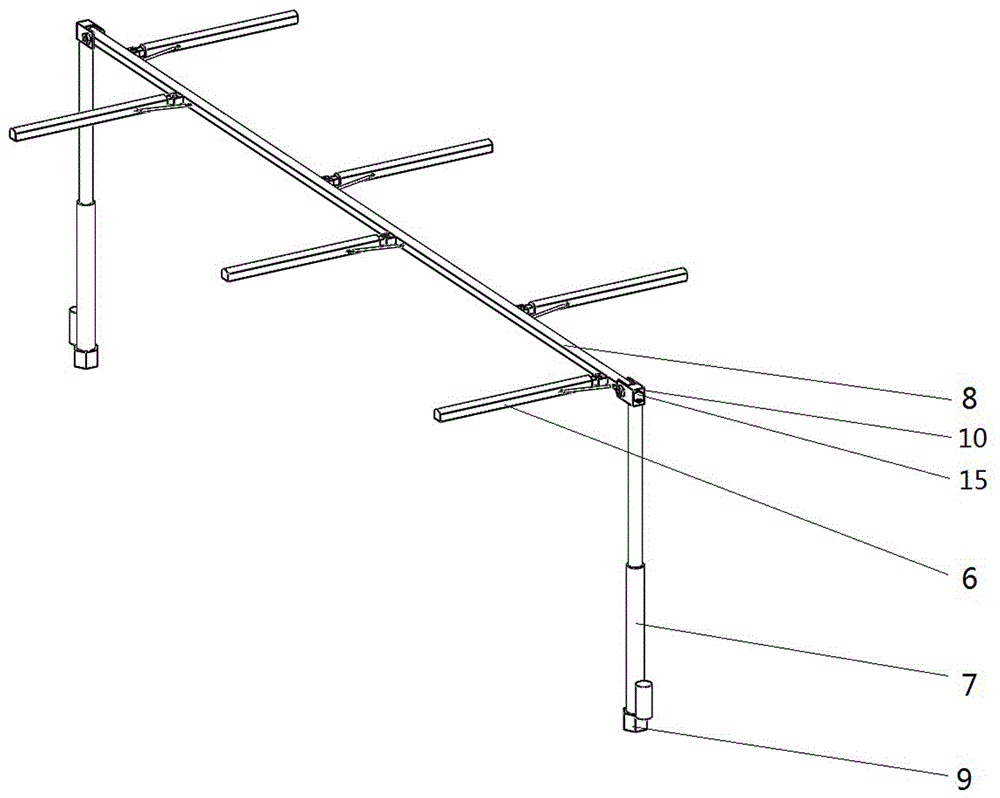

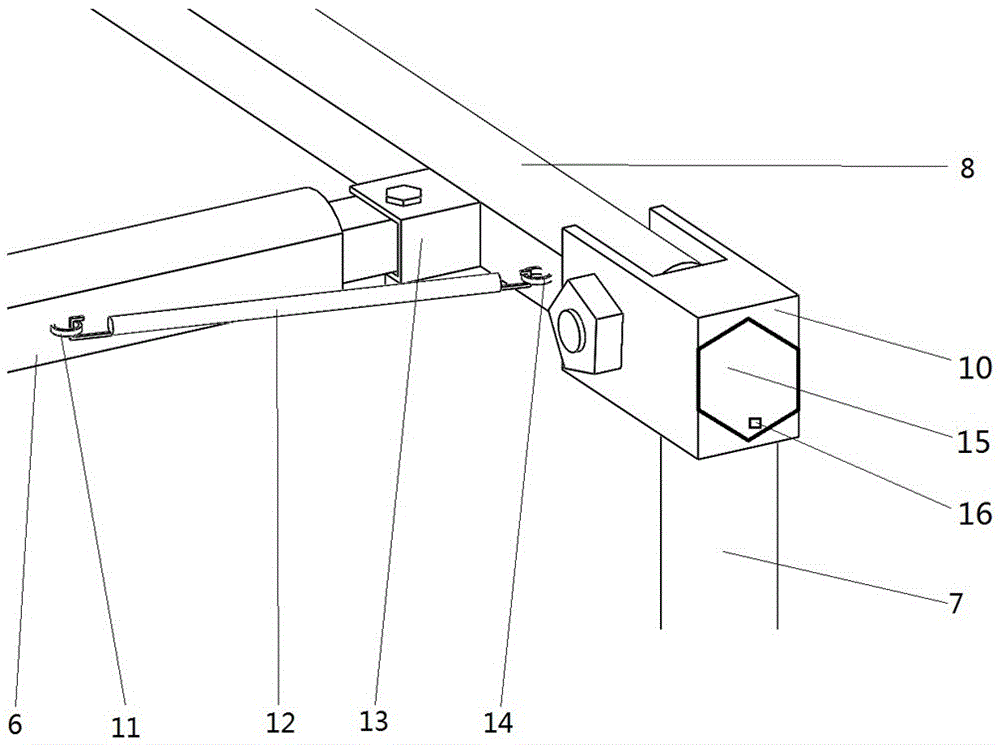

[0024] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, an automatic lifting broiler perching frame includes an automatic feeding line 3, an automatic water feeding line 2 and a net bed, and it is characterized in that: the net bed 1 includes a net 1 and a support rod 4 below the net 1, The supporting rod 4 is arranged between the automatic feeding line 3 and the automatic water feeding line 2, the supporting rod 4 is parallel to the automatic feeding line 3 and the automatic water feeding line 2, and a connecting rod 5 is arranged between the supporting rods 4, and the supporting rod 4 An internally threaded nut 9 is arranged on the top, and the internally threaded nut 9 is connected with a lifting rod 7. The lower part of the lifting rod 7 is provided with an externally threaded bolt, and the externally threaded bolt is connected with the internally threaded nut. The top of the lifting rod 7 is provided with a support 10. The side of...

Embodiment 2

[0030] Embodiment 2, the experimental comparison between the present invention and common mesh bed.

[0031] Choose 200 healthy broilers with similar body weight, and the flocks are randomly divided into two groups, 100 in each group, respectively the experimental group and the control group, wherein the experimental group is put into the net bed of the present invention to raise, and the control group is placed The external environment of the two groups of broilers was the same, and the feeding feed, feeding amount and feeding time were all the same. After 30 days of continuous feeding, the incidence rates of breast cysts and leg diseases in the two groups of broilers were shown in Table 1:

[0032] Table 1: Incidence of breast cysts and leg diseases in broilers

[0033] test group control group Chest cyst incidence 3% 58% incidence of leg disease 4% 62%

[0034] From the table, it can be clearly seen that the experimental group is raised in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com