Sugar cooking pot having function of pasting prevention

A technology of boiling sugar pots and functions, which is applied in the fields of confectionery, confectionary industry, food science, etc., and can solve the problems of easy-to-stick pans and achieve the effect of preventing sticky pans and overflowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

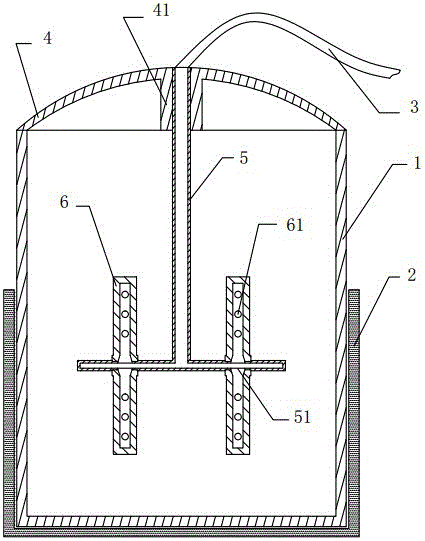

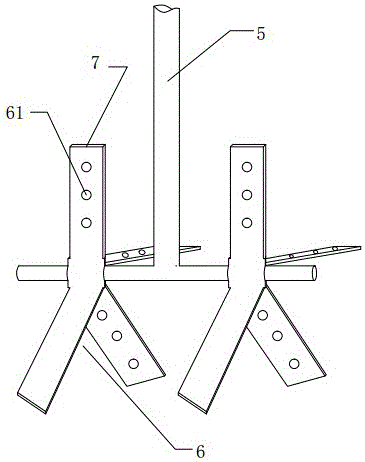

[0021] The reference signs in the accompanying drawings include: pot body 1, heating layer 2, air pipe 3, cover 4, ventilation shaft 5, fan rotor 6, hollow fan blade 7, through hole 41, hollow inlet 51, and air outlet 61.

[0022] Such as figure 1 As shown: the heating layer 2 is installed on the outer bottom of the pot body 1, the upper end of the pot body 1 is connected to the cover 4, the cover 4 is provided with a through hole 41, the through hole 41 is externally connected to the air pipe 3, and the through hole 41 is provided with an internal thread, in an inverted T shape The ventilation shaft 5 is threadedly connected in the through hole 41, the interior of the ventilation shaft 5 is provided with a hollow channel, two fan rotors 6 are symmetrically socketed on both sides of the ventilation shaft 5, the rotation direction of the fan rotor 6 is perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com