Coating and cooking utensil

A cooking equipment and coating technology, applied in the field of materials, can solve the problems of restricting the industrialization process of quasi-crystal coatings, the need for improvement of quasi-crystal coatings, and the high production cost of quasi-crystal coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

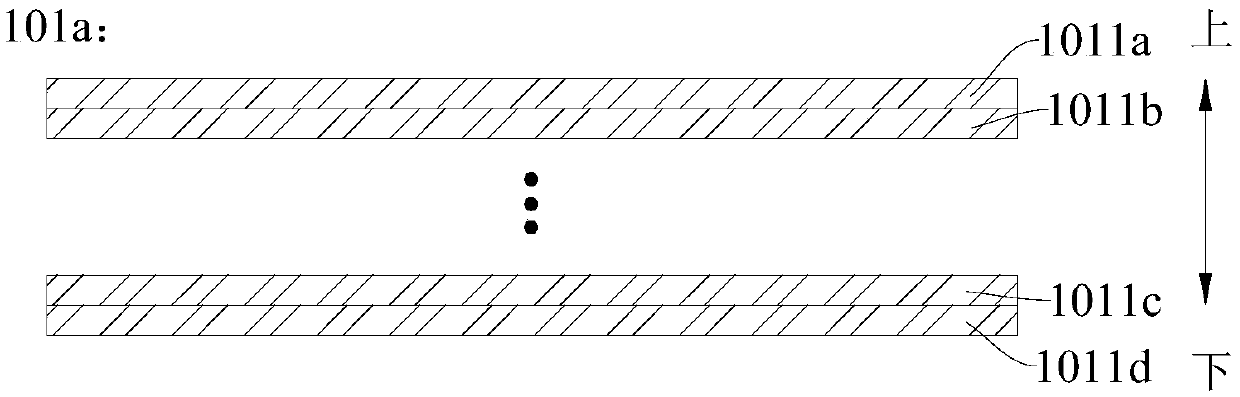

[0089] The coating includes a first sub-coating layer and a second sub-coating layer stacked sequentially from bottom to top, the quasi-crystalline material forming the first sub-coating has a particle size of 150-300 microns, and the quasi-crystalline material forming the second sub-coating The particle size of the material is 20-150 microns.

[0090] The steps for preparing the coating are:

[0091] 1. Melting the alloy raw material into an alloy ingot according to the ratio of atomic numbers of Al: Cu: Fe: Cr = (60-70): (15-25): (5-15): (5-15).

[0092] 2. Atomized pulverization: Under vacuum or protective atmosphere, use pulverizing equipment to make quasi-crystal powder.

[0093] 3. Spheroidization: the powder is spheroidized and sieved to obtain powders with particle sizes of 20-150 microns and 150-300 microns respectively.

[0094] 4. Substrate surface cleaning: Use alcohol, trichlorethylene or pure water plus ultrasonic waves to clean and dry the surface of the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com