Glass distillation device and use method thereof

A technology of distillation device and glass, applied in the field of distillation, can solve the problems of paste pot and brewing equipment being difficult to observe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

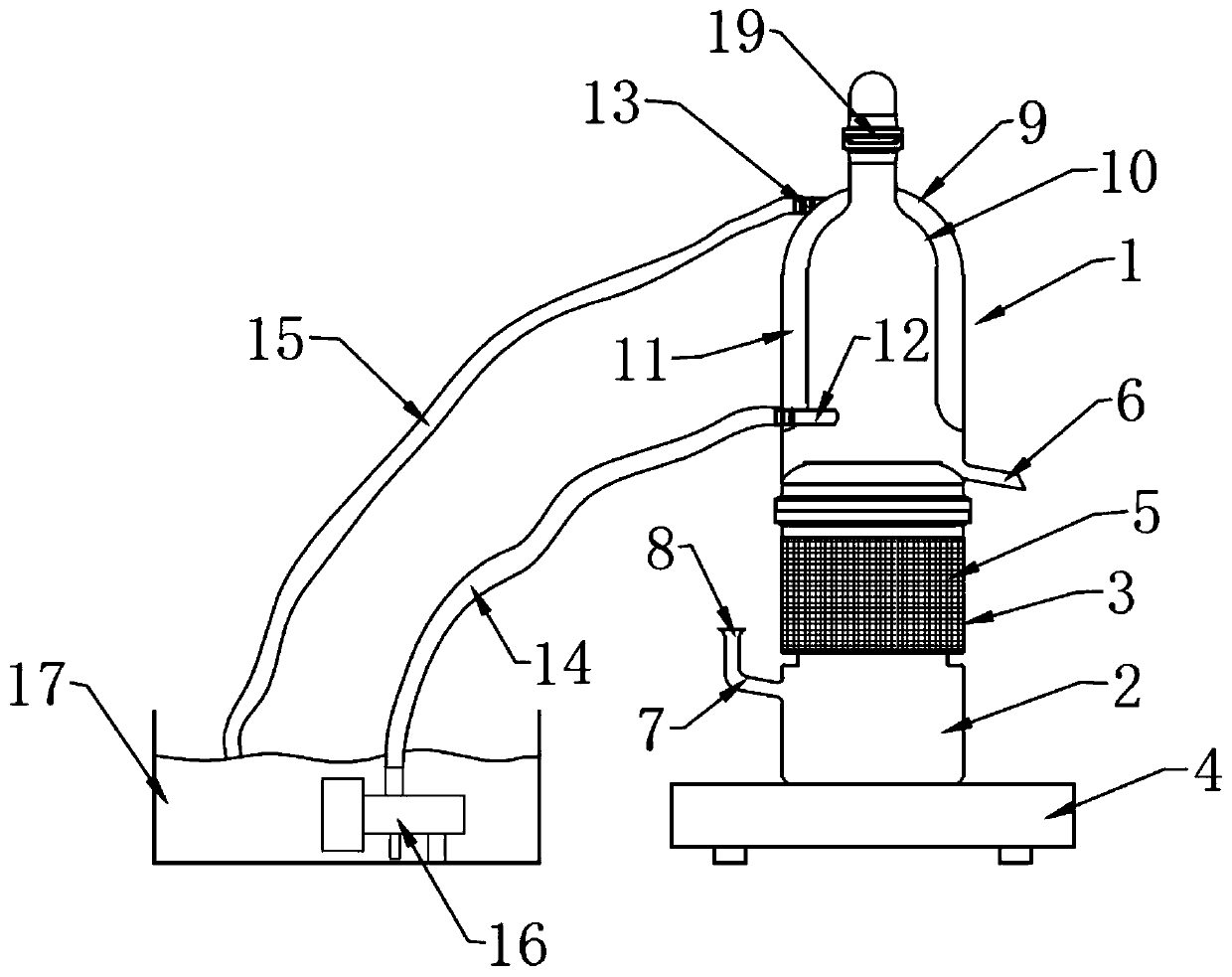

[0031] This embodiment discloses a glass distillation device. The glass distillation device includes: a distillation bottle 1, an evaporating dish 2, a steaming frame 3 and a heating device 4, and the heating device 4 is arranged at the bottom of the evaporating dish 2 to heat the evaporating dish 2. Heating, the top of the evaporating dish 2 is open, the side wall of the evaporating dish 2 is connected to the exhaust pipe 7, and the height of the water added in the evaporating dish 2 is lower than the height of the connection between the exhaust pipe 7 and the side wall of the evaporating dish 2, said The exhaust pipe is bent, and the exhaust port 8 is vertically upwards to prevent water from entering the exhaust pipe 7 and affect the exhaust.

[0032] The steaming rack 3 is installed on the top of the evaporating dish 2, the upper end of the steaming rack 3 is open and provided with clips, the distiller's grains 5 are placed in the steaming rack 3, and the distillation bottle...

Embodiment 2

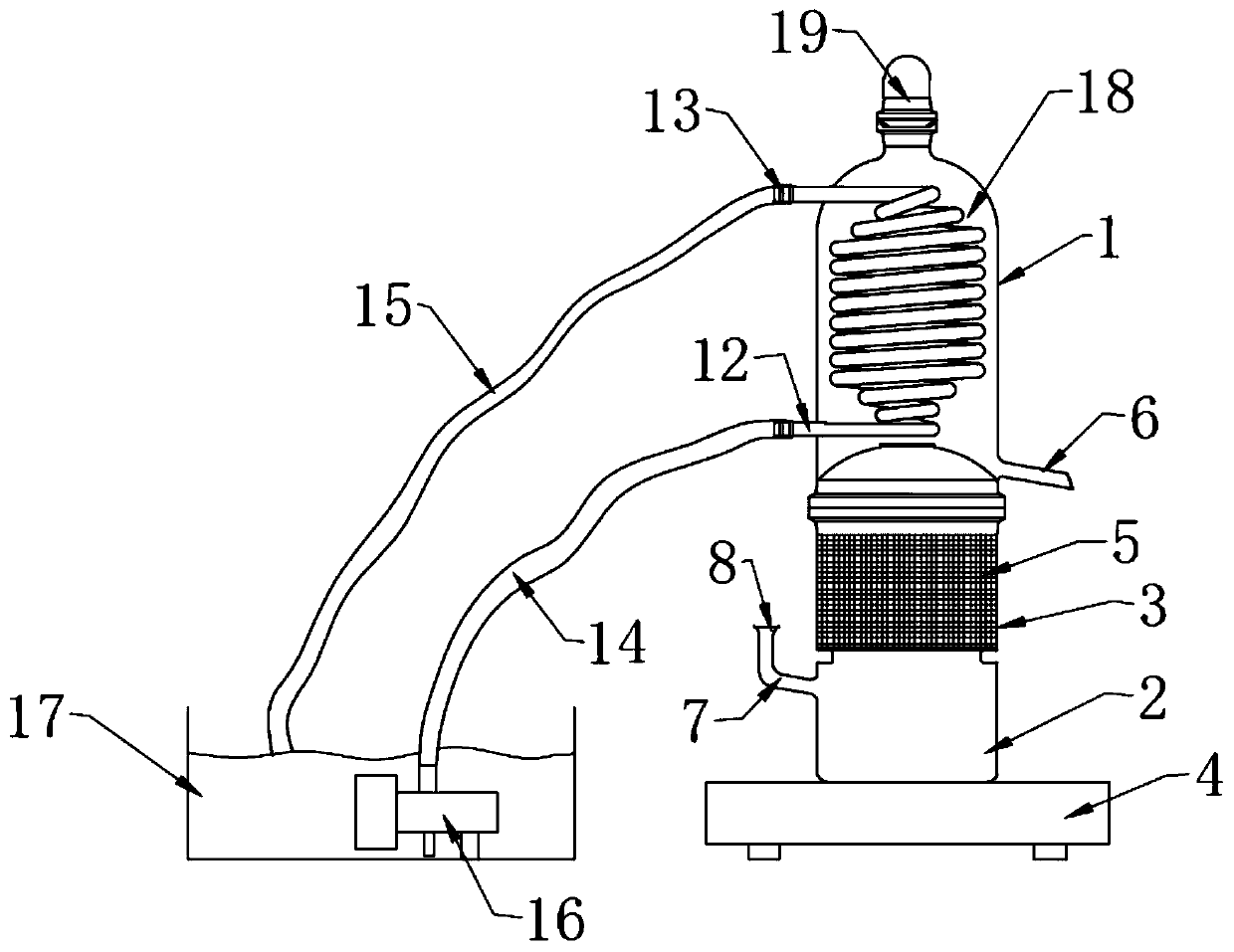

[0037] This embodiment discloses another glass distillation device, which includes: a distillation bottle 1, an evaporating dish 2, a steaming frame 3 and a heating device 4, and the heating device 4 is arranged at the bottom of the evaporating dish 2 opposite to the evaporating dish 2 Heating is carried out, the top of the evaporating dish 2 is open, and the side wall of the evaporating dish 2 is connected to the exhaust pipe 7, and the height of the water added in the evaporating dish 2 is lower than the height of the joint between the exhaust pipe 7 and the side wall of the evaporating dish 2, so The exhaust pipe is bent, and the exhaust port 8 is vertically upward to prevent water from entering the exhaust pipe 7 and affecting the exhaust.

[0038] The steaming rack 3 is installed on the top of the evaporating dish 2, the upper end of the steaming rack 3 is open and provided with clips, the distiller's grains 5 are placed in the steaming rack 3, and the distillation bottle ...

Embodiment 3

[0042] This embodiment discloses a method of using a glass distillation device, the method of using is:

[0043] Before distillation, add water in the evaporating dish 2 to prevent the liquid level from exceeding the connection between the exhaust pipe 7 and the side wall of the evaporating dish 2;

[0044] Turn on the water pump 16 to draw water, and extract the condensed water from the water tank 17 into the annular airtight cavity 11 or the annular condenser between the outer wall 9 and the inner wall 10 of the distillation bottle 1;

[0045] Until the water outlet 13 starts to discharge water, start the heating device 4 to start heating the evaporating dish 2;

[0046] The distiller's grains 5 in the steaming rack 3 are distilled, and the fraction enters the distillation bottle 1;

[0047] The distilling bottle 1 condenses the fraction, and the distilled components flow out from the material outlet 6;

[0048] Distillation finishes, closes heating device 4 earlier, keeps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com