Method for regulating multi-site processing intensity uniformity of in-process products in tobacco drum drying process

A drum drying and consistent technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the risks of universality and application timeliness, the quality consistency of multi-point processed products is difficult to guarantee, and the physical and chemical indicators of products are prone to appear larger. problems such as deviations, to avoid control inaccuracies, reduce the possibility of drastic changes, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

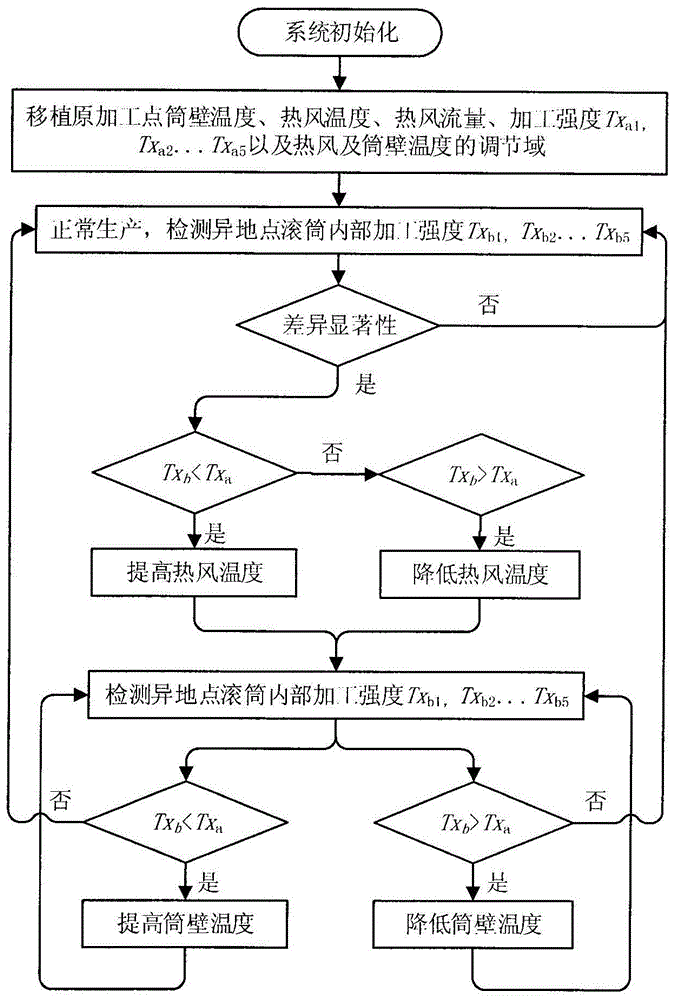

[0033] The regulation and control method of the present invention is further described below in conjunction with accompanying drawing and implementation example:

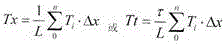

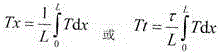

[0034] In this case, a brand of modular formula shredded tobacco is used for production, and the processing intensity obtained by integrating the processing path ratio Tx As an example ( Tt adjustment method and Tx similar), the specific control steps are as follows:

[0035] 1. In the normal drum drying production at site A, set the drum wall temperature to 150°C and the hot air temperature to 100°C, and use the tobacco material drum heat and humidity treatment online monitoring system to detect the axial temperature distribution of the tobacco material in the drum drying equipment at the original processing point.

[0036] 2. The computer collects the temperature on the product surface of land A continuously for 5 times, according to the processing intensity introduced in the present invention Tx Calculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com