Filtering device for painting room

A filtration device and spray booth technology, applied in the directions of dispersed particle filtration, separation method, dispersed particle separation, etc., can solve the problems of high processing cost, decreased adsorption capacity of absorbent, secondary pollution, etc., to reduce environmental pollution and ensure effective The effect of dust removal and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

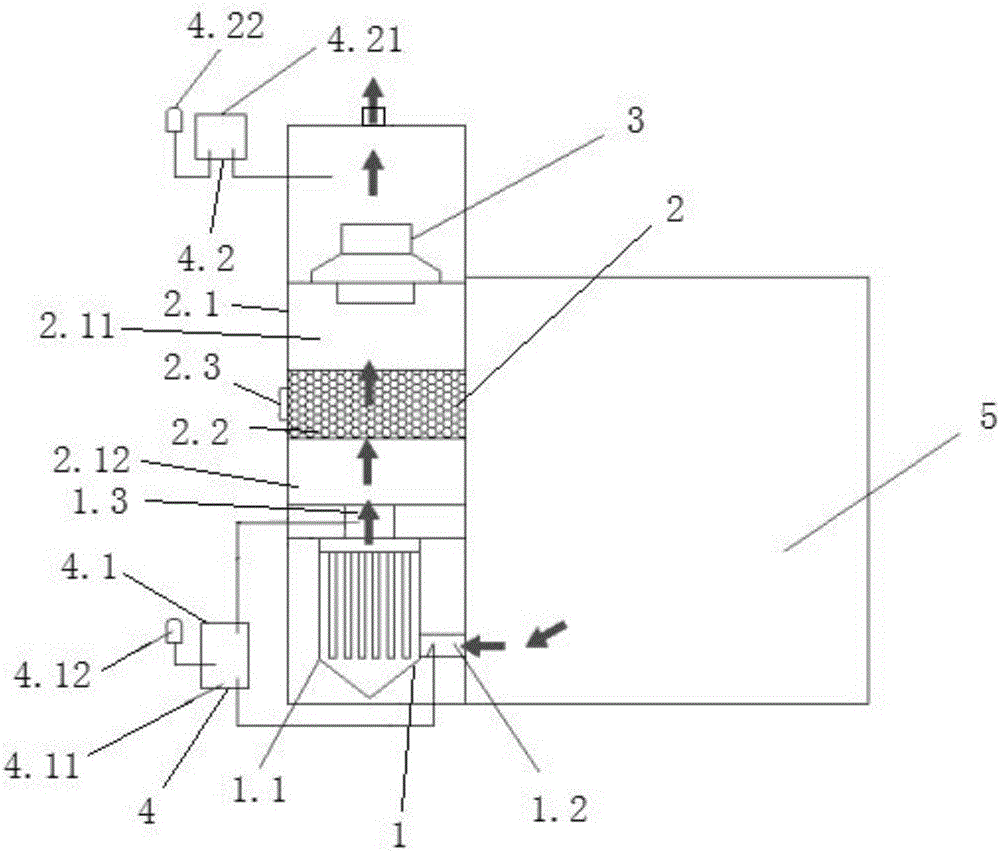

[0033] see figure 1 , a filter device for a spray booth, including at least one set of filter elements communicated with the exhaust gas outlet of the spray booth (here, at least two sets of filter elements arranged side by side can also be used according to actual conditions), the filter A single piece includes bag dust removal part 1, activated carbon adsorption part 2, exhaust part 3 and parameter measurement part 4, details are as follows:

[0034] The bag dust removal unit 1 includes a bag dust removal body 1.1 and an inlet 1.2 and an outlet 1.3 arranged on the bag dust removal body 1.1, and the inlet 1.2 communicates with the exhaust gas outlet of the spray booth 5 .

[0035] The activated carbon adsorption component 2 includes a housing 2.1 and an activated carbon adsorption layer 2.2 detachably arranged in the middle of the housing 2.1. The activated carbon adsorption layer 2.2 divides the housing 2.1 into an independently arranged upper cavity 2.11 and The lower cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com