Method for repairing inner wall of acid-making absorption tower

A repair method and acid absorption tower technology, applied in separation methods, chemical instruments and methods, sulfur compounds, etc., can solve problems such as blockage of sulfuric acid pumps and sulfuric acid coolers, affecting the production stability of the acid system, and increasing pipeline maintenance costs, etc. , to achieve the effects of improving stability, eliminating personal injury accidents, reducing spare parts consumption and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

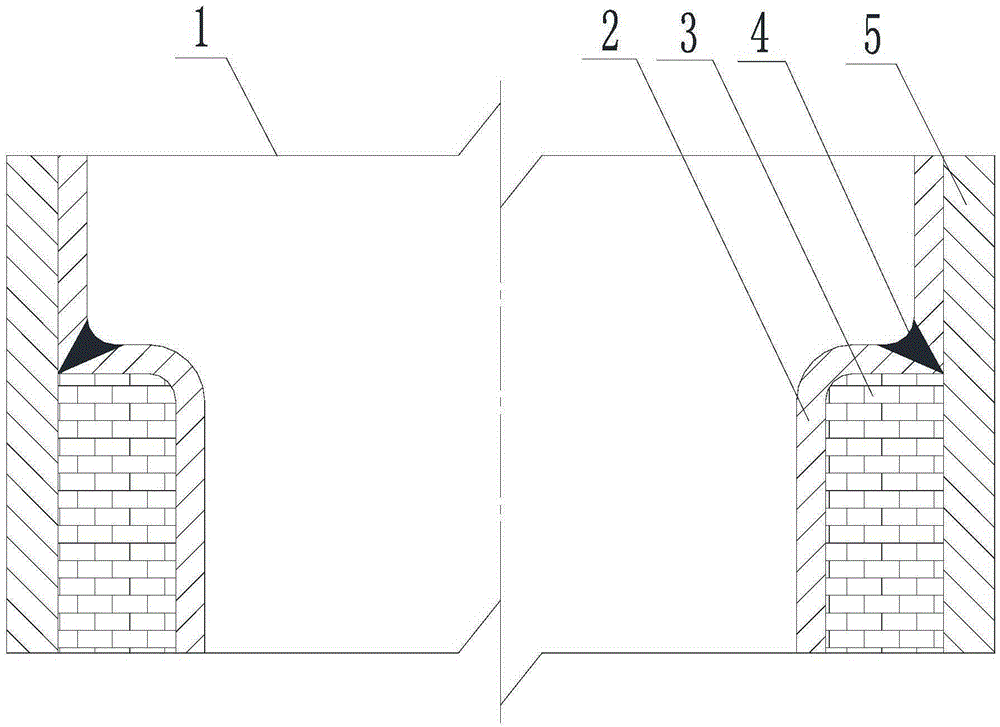

[0016] Depend on figure 1 It can be seen that the upper tower body 1 of the absorption tower includes the outer tower wall steel plate 5 and the lead-lined layer 2 and the brick-lined layer 3 of the inner lining.

[0017] The concrete method and steps of repairing the inner wall of the acid absorption tower of the present invention are:

[0018] 1. Remove the upper connecting pipe of the absorption tower, hang the upper body 1 head of the absorption tower with a crane and stabilize it, then remove the fasteners at the flange connection part, and then use a crane to lift the upper body 1 head of the absorption tower Lift it up and put it on the ground.

[0019] 2. Use a portable cutter or blade to cut out the manhole 1.65m down from the upper body 1 of the absorption tower, separate the lead-lined layer 2 from the steel plate 5 on the tower wall, and use a stone pencil to clean the lead-lined layer 2 and the steel plate on the tower wall. 5. Mark the line, then hang the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com