Key-connection combined vertical roll

A technology of vertical rolls and connecting parts, which is applied in the direction of rolls, metal processing equipment, metal rolling, etc., can solve the problems of large energy consumption, reduced production costs, and large assembly stress, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

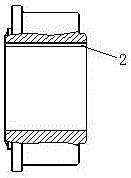

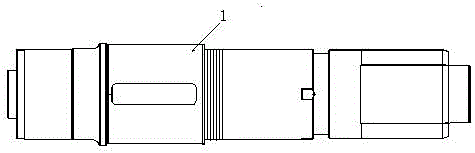

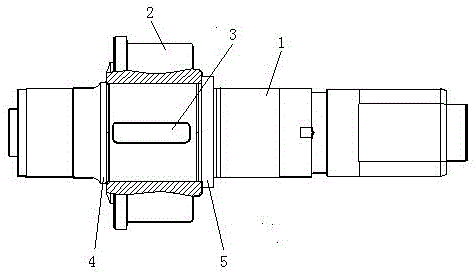

[0024] like figure 1 , 2 As shown in , 3, a key connection combination vertical roll, including a roll shaft 1 and a roll sleeve 2, the roll shaft 1 includes the roll neck at both ends and the connecting portion of the middle section, the diameter of the connecting portion is greater than the diameter of the roll neck at both ends, and the roll shaft The connecting part of the middle section of 1 and the roller sleeve 2 are interference fit, and the interference fit of the interference fit is relatively small, which is 0.05-0.15mm. The roller sleeve 2 is fitted and connected on the outer circumference of the connection part of the middle section of the roller shaft 1 through a key 3, and the key 3 is an ordinary flat key. Through the double connection of key 3 connection and interference fit, it overcomes the problems that the traditional only applicable interference connection method has a large amount of interference and high precision requirements for dimensional matching....

Embodiment 2

[0028] like figure 1 , 2 As shown in , 4 and 5, a keyed joint combination vertical roll includes a roll shaft 1 and a roll sleeve 2, the roll shaft 1 includes a roll neck at both ends and a connecting portion in the middle, and the diameter of the connecting portion is greater than the diameter of the roll neck at both ends, The connecting portion of the middle section of the roller shaft 1 and the roller sleeve 2 are interference fit, and the interference fit of the interference fit is relatively small, being 0.05-0.15mm. The roller sleeve 2 is fitted and connected to the outer circumference of the connecting part of the middle section of the roller shaft 1 through the key 3 . Through the double connection of key 3 connection and interference fit, it overcomes the problems that the traditional only applicable interference connection method has a large amount of interference and high precision requirements for dimensional matching. The problem of high production cost caused ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com