Method for preparing organic silicon cottonseed oil-based lubricating oil base oil

A technology for lubricating base oil and cottonseed oil, which is applied in the directions of lubricating composition, base material, petroleum industry, etc., can solve the problems of expensive catalyst and high production cost, and achieve the effects of low cost, simple preparation method and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

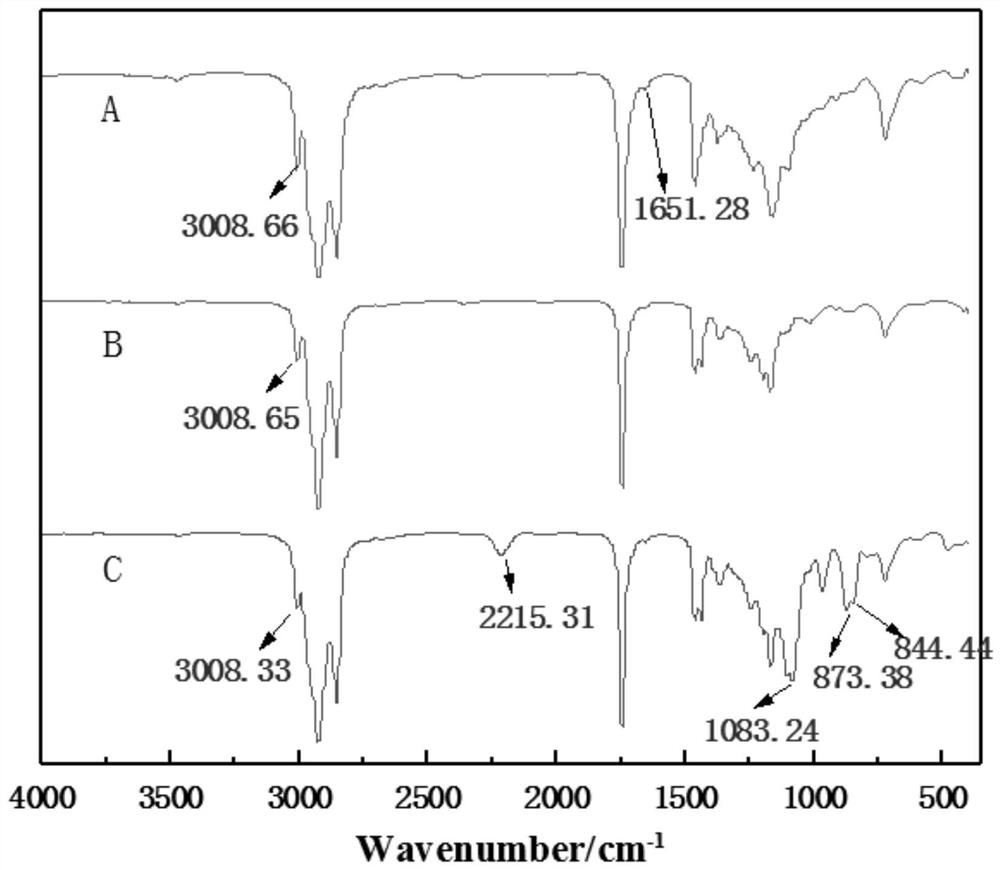

Image

Examples

Embodiment 1

[0025] Put 1g of NaOH into 50mL of methanol and stir magnetically. After the NaOH is completely dissolved, transfer it to a three-necked flask with a condensing reflux device, then add 15mL of cottonseed oil (refined), and place it in an oil bath with a stirring and temperature display function to stir. Heated to 55°C and reacted for 2h. Leave to stand for layering, separate the liquids, wash the upper layer solution with hot distilled water, and vacuum-dry to obtain cottonseed oil methyl ester. Add the catalyst Fe to the cottonseed oil methyl ester, then add 20 g of triethylsilane, raise the temperature to 180° C. for reflux hydrosilylation reaction, stop the reaction after 12 hours, and cool down. The solid catalyst is separated by centrifugation, and then the light components are removed by distillation under reduced pressure, and then centrifuged again to finally obtain the silicone cottonseed oil lubricating oil base oil.

[0026] The catalyst can also be one or a combin...

Embodiment 2

[0028] Put 1g of KOH into 50mL of methanol and stir magnetically. After the KOH is completely dissolved, transfer it to a three-necked flask with a condensing reflux device, and then add 15mL of cottonseed oil and petroleum ether solution (after extracting cottonseed powder with two-liquid phase solvent petroleum ether + methanol) , solid-liquid separation, static layering, the upper layer is cottonseed oil and petroleum ether solution), placed in an oil bath with a stirring temperature display function, stirred and heated to 55 ° C, and reacted for 2 hours. Leave to stand for layering, separate the liquids, wash the upper layer solution with hot distilled water, and vacuum-dry to obtain cottonseed oil methyl ester. Add the catalyst Zn to the cottonseed oil methyl ester, then add 10 g of trimethylsilane, raise the temperature to 170° C. to carry out the reflux hydrosilylation reaction, and stop the reaction after 12 hours of reaction. The solid catalyst is separated by centrif...

Embodiment 3

[0030] Put 1g of NaOH into 50mL of methanol and stir magnetically. After the NaOH is completely dissolved, transfer it to a three-necked flask with a condensing reflux device, then add 15mL of refined cottonseed oil (buy cottonseed oil in barrels), and place it in a thermostat with a stirring and temperature display function. Stir and heat in an oil bath to 55°C, and react for 2 hours. Leave to stand for layering, separate the liquids, wash the upper layer solution with hot distilled water, and vacuum-dry to obtain cottonseed oil methyl ester. Add the catalyst Ni to the cottonseed oil methyl ester, then add 10 g of diethylchlorosilane, raise the temperature to 160° C. to carry out the reflux hydrosilylation reaction, and stop the reaction after 12 hours of reaction. The solid catalyst is separated by centrifugation, and then the light components are removed by distillation under reduced pressure, and then centrifuged again to finally obtain the silicone cottonseed oil lubricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com