Lithium battery control module thermal compression welding method and lithium battery control module obtained after welding

A technology of thermocompression welding and control modules, which is applied in the direction of secondary batteries, welding equipment, non-electric welding equipment, etc., can solve the problems of welding unreliability and false welding, and achieve the purpose of solving false welding, improving reliability and consistent welding sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

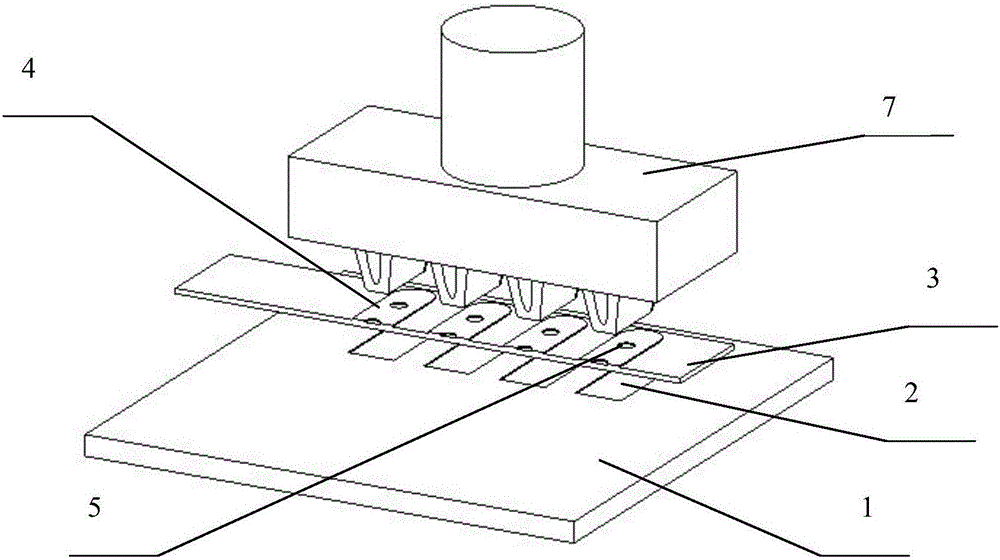

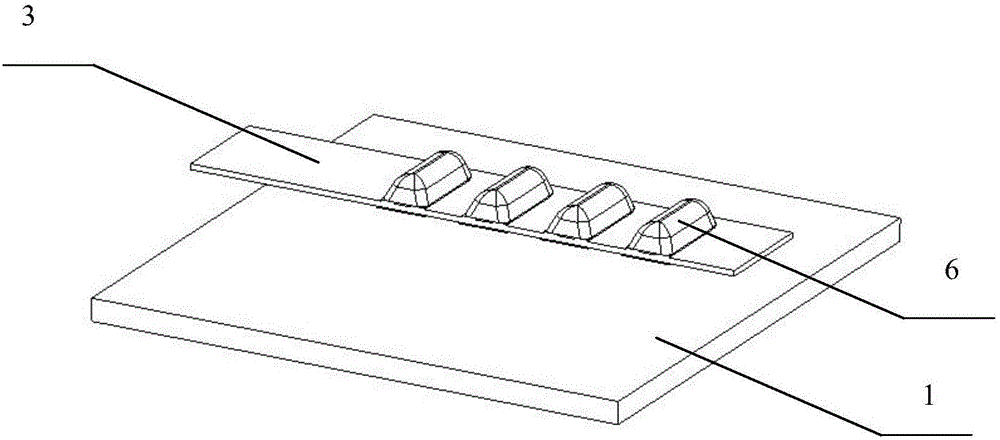

[0020] Such as figure 1 As shown, a lithium battery control module hot-press welding method, the lithium battery control module includes a soft board 3 and a hard board 1, the soft board 3 is provided with a soft board hot-press pad 4, and the hard board 1 is provided with a hard board The hot-pressed pad 2 of the board, the hot-pressed pad 4 of the soft board and the hot-pressed pad 2 of the hard board are connected by hot-press welding, and it is characterized in that the hot-press welding method includes the following steps: 1. Hole 5 is opened on the top, and tin is printed on the hot-press pad 2 of the hard board and the hot-press pad 4 of the soft board, and the hot-press pad 2 of the hard board and the hot-press pad 4 of the soft board are superimposed together; Align the groove at the end of the thermocompression welding head with the hole 5 on the thermocompression pad 4 of the soft board for thermocompression welding, so that the printed tin on the thermocompression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com