Air-pressure type quick-replacement clamp

A quick-change fixture and pneumatic technology, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problem that the equipment can only be idle, and achieve the effect of reducing investment costs, ensuring production nodes, and reducing downtime

Inactive Publication Date: 2017-05-24

GUIZHOU HONGLIN MACHINERY

View PDF8 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the parts need to be sent to the measuring room for inspection during the processing, the parts must be disassembled from the fixture, and the equipment can only be idle during the inspection time of the parts.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

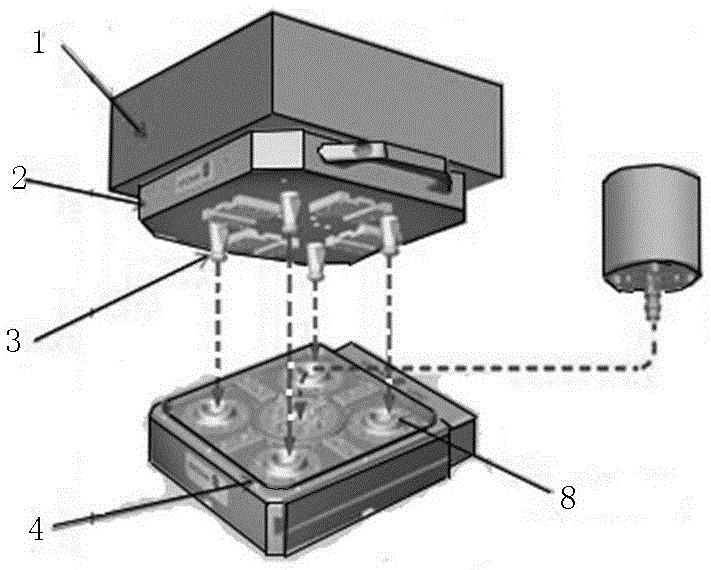

[0061] According to the size and cutting force of the RCB10B-630-02 shell, select the base plate with four pull studs (such as Figure 5 shown), the model is ER-063136, and the corresponding pull stud model is ER-041461 (1 set of 4 pieces).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an air-pressure type quick-replacement clamp. The air-pressure type quick-replacement clamp consists of a special clamp (1) for clamping parts, a supporting plate (2), blind rivets (3) and a foundation plate (4), wherein the supporting plate (2) and the special clamp (1) are designed as a whole body; the special clamp (1) comprises a bottom plate and a press plate, which are included by a traditional clamp; the blind rivets (3) comprise positioning blind rivets (5), compensation blind rivets (6) and pure blind rivets (7); one or more positioning blind rivets (5) and one compensation blind rivet (6) are arranged under the bottom plate; MTS chucks (8) which numerically correspond to the blind rivets (3) are integrated on one customized bottom plate, so that the foundation plate (4) is formed; a central hole is formed in the foundation plate (4); each single MTS chuck (8) is positioned by a gapless prism which is provided with an internal ring positioning surface and an external ring positioning surface; a blind rivet hole is formed in each of the MTS chucks (8); and the foundation plate (4) is provided with air channels (9) of an air pressure device, holding frames (10), springs (14) and steel balls (11). Through the adoption of the air-pressure type quick-replacement clamp disclosed by the invention, five sides can be processed in one clamping process; different procedures of the same part or different parts can be processed on one machine tool; the air-pressure type quick-replacement clamp can be clamped on different equipment once for processing; and a part does not need to be demounted during processing, after the part with the clamp is moved onto inspection equipment and inspected, the inspected part can be directly returned onto processing equipment to continue to be processed.

Description

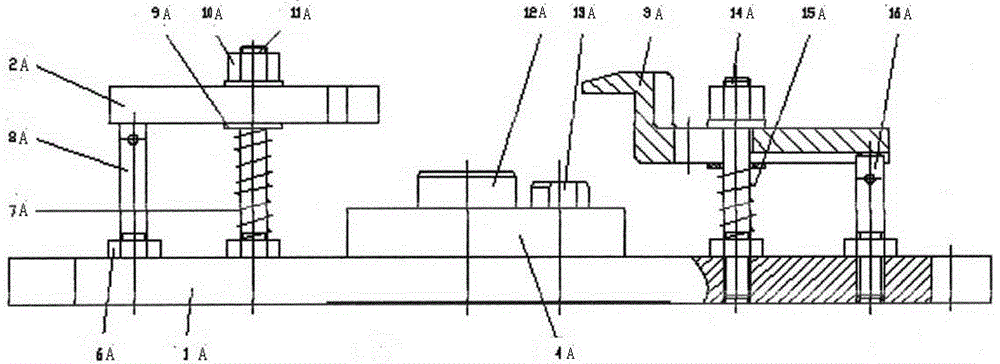

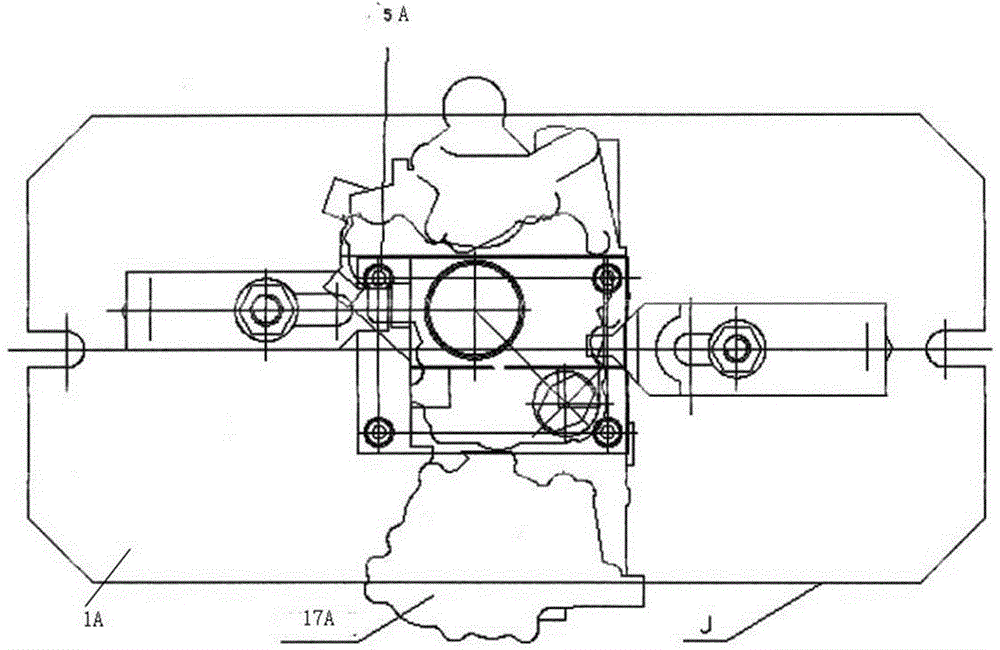

technical field [0001] The invention relates to the processing of shell parts and components in various products, in particular to a pneumatic quick-change fixture. Background technique [0002] Traditional fixtures and processing technology pay attention to single-machine precision and ignore transmission precision; design, process, processing, and inspection standards are not uniform; process conversion depends on fixture positioning, the workpiece leaves the fixture during the conversion, and a set of fixtures is configured for a part of a process; no flexibility, no "Interrupt processing". Take shell parts as an example. [0003] Traditional fixture structure and alignment method (see Figure 1): 1A, bottom plate, 2A, pressure plate 1, 3A, pressure plate 2, 4A, flat plate, 5A, screw, 6A, nut 1, 7A, spring 1, 8A, support 1, 9A, washer, 10A, nut 2, 11A, bolt 1, 12A, cylindrical pin, 13A, diamond pin, 14A, bolt 2, 15A, spring 2, 16A, support 2, 17A, processed parts; it is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23Q3/06

CPCB23Q3/06

Inventor 何林美周可平郭春林黄小梅

Owner GUIZHOU HONGLIN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com