Rail system and solar power station cleaning robot using same

A robot and solar technology, applied in the field of robotics, can solve the problems of inability to guarantee the quality of cleaning, damage to solar panels, impact and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

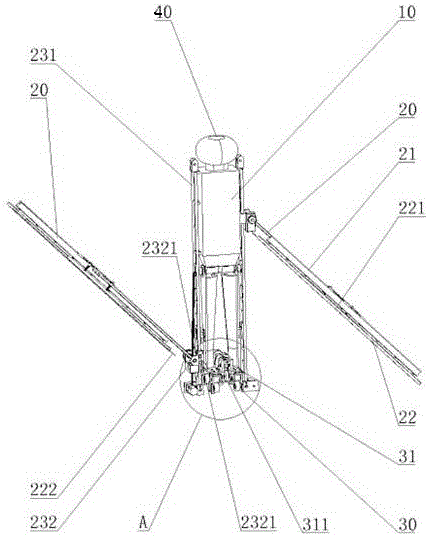

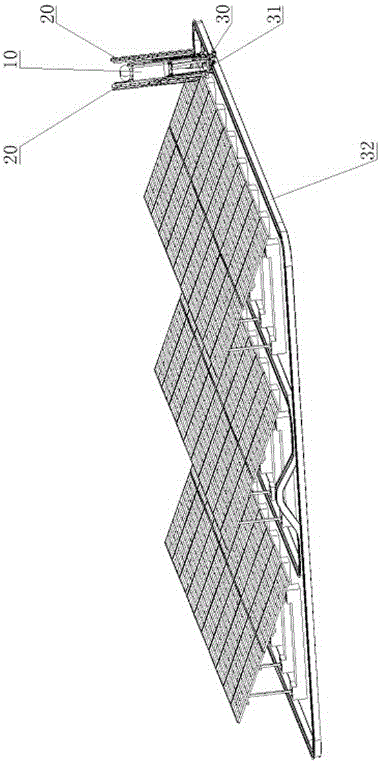

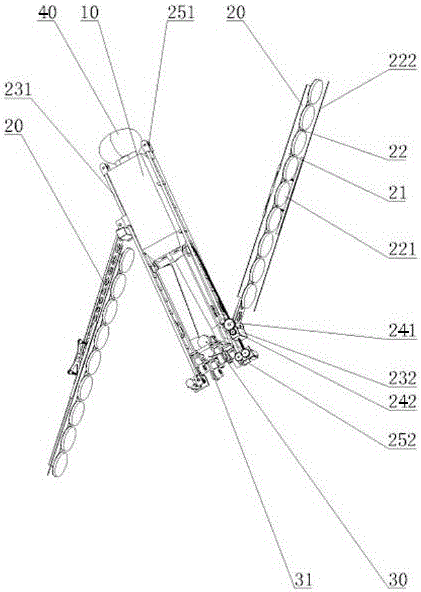

[0022] Such as Figures 1 to 5 As shown, a track system includes a track 32 and a moving device 30 matched with the track 32, the track 32 includes a left bearing part 321, a middle bearing part 322 and a right bearing part 323, the left bearing A first groove 324 is arranged between the part 321 and the middle bearing part 322, a second groove 325 is arranged between the right side bearing part 323 and the middle bearing part 322, and the middle bearing part 322 The left side is perpendicular to the groove bottom of the first groove 324, the right side of the middle bearing part 322 is perpendicular to the groove bottom of the second groove 325, and the mobile device 30 includes a longitudinal guide wheel 331 and a transverse guide wheel 332. And the power wheel 311 driven by the walking power device, the power wheel 311 is in contact with the upper surface of the middle bearing part 322, and the longitudinal guide wheels 331 are arranged in pairs and distributed between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com