Method for grabbing and loading industrial wastes by variable-degree-of-freedom connecting rod mechanism comprising rotating pair locking device

A link mechanism and industrial waste technology, applied in the field of machinery, can solve the problems of reducing the weight of the mechanism, motion inertia, volume and cost, installation at the joint position, and high precision requirements, to overcome the high precision requirements of hydraulic system components and reduce weight. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

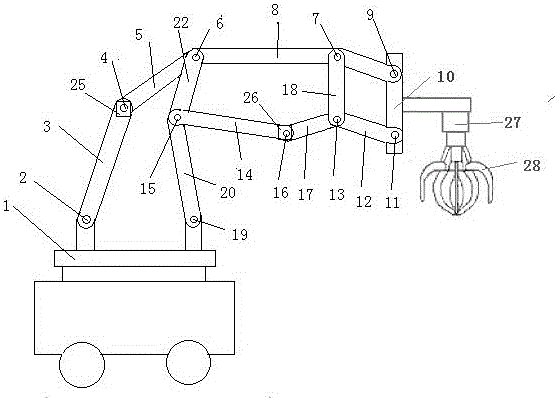

[0008] A variable-degree-of-freedom link mechanism including a rotating pair locking device for grasping and loading industrial waste, characterized in that the variable-degree-of-freedom link mechanism including a rotating pair locking device includes: a base 1, a boom telescopic mechanism , the lower arm lifting mechanism, the wrist link holding mechanism, the servo drive device, the first locking device 25 and the second locking device 26; the base 1 is installed on a movable rotary platform; Composed of four connecting rods 5, the first active rod 3, the second active rod 20 and the first connecting rod 22, the first active rod 3 is connected to the base 1 through the first rotating pair 2, and the other end of the first active rod 3 passes through The second rotating pair 4 is connected with the fourth connecting rod 5, the second active lever 20 is connected with the base 1 through the third rotating pair 19, and the other end of the second active lever 20 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com