Side draw pin lateral injection mold

A technology of injection mold and slanted guide post, which is applied in the field of mold production and slanted guide post lateral injection mold, can solve the problems of complex structure and high cost, and achieve the effect of improving product precision, low cost, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

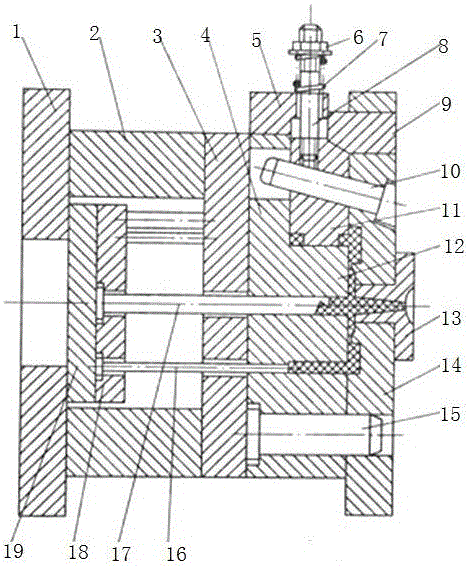

[0014] Embodiment 1: see figure 1 , a lateral injection mold with inclined guide columns, the injection mold includes a movable mold bottom plate 1, a cushion block 2, a support plate 3, a movable template 4 and a positioning device, and the cushion block 2 is arranged on the movable mold seat plate 4 and the support Between the plates 3, a push plate 19 and a push rod fixing plate 18 are arranged under the pad 2, and the injection mold also includes a fixed mold seat plate 14, a sprue sleeve 13 and a core 12, and the core 12 is set On one side of the movable template, the sprue sleeve is arranged on the fixed mold seat plate.

Embodiment 2

[0015] Example 2: see figure 1 , as an improvement of the present invention, the injection mold also includes a wedge block 9, an oblique guide post 10 and a side core slider 11, the side core slider is arranged above the core, and the oblique guide post Set above the side core slides. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0016] Embodiment 3: see figure 1 , as an improvement of the present invention, the positioning device includes a limit block 5, a nut 6, a spring 7, a gasket and a slider pull rod 8, the slide pull rod is arranged above the inclined guide post, and the slide pull rod is set There are nuts and springs, and the limit block is arranged on the moving touch board. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com