Rivet bucker spin riveting head for necking down forming of stainless steel inner barrel of roller washing machine

A drum washing machine and stainless steel technology, which is applied in the field of washing machine processing equipment, can solve the problems of wrinkles at the joint between the neck and the barrel, deformation of the neck structure, and influence on the installation of plastic parts, so as to improve stability, accuracy, and force balance , The effect of stable molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

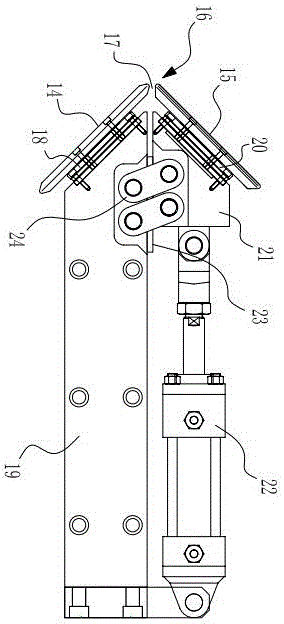

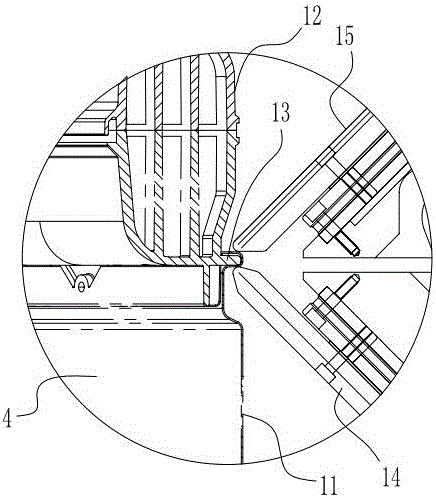

[0013] Such as figure 1 , 2 As shown, a rotary riveting head for forming the stainless steel inner barrel of a drum washing machine, including rotating the barrel wall 11 of the stainless steel inner barrel 4 from the barrel body to the direction of the two barrel mouths and pressing it against the plastic part 12 The fixed forming pressing plate 14 and the movable forming pressing plate 15 on the connection boss 13 of the connecting boss 13, one end of the fixed forming pressing plate 14 and the movable forming pressing plate 15 are close to each other to form a spin riveting end 16, and a ring for spinning riveting is formed in the spinning riveting end 16. Accommodate the rotary riveting forming area 17 of the connecting boss 13 of the plastic part 12, the fixed molding pressing plate 14 is fixed on the transverse support plate 19 by the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com