Cross seal clamping mechanism

A clamping mechanism and horizontal sealing technology, which is applied in packaging sealing/fastening, transportation packaging, packaging, etc., can solve the problems of poor sealing effect of sealing device or clamping device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

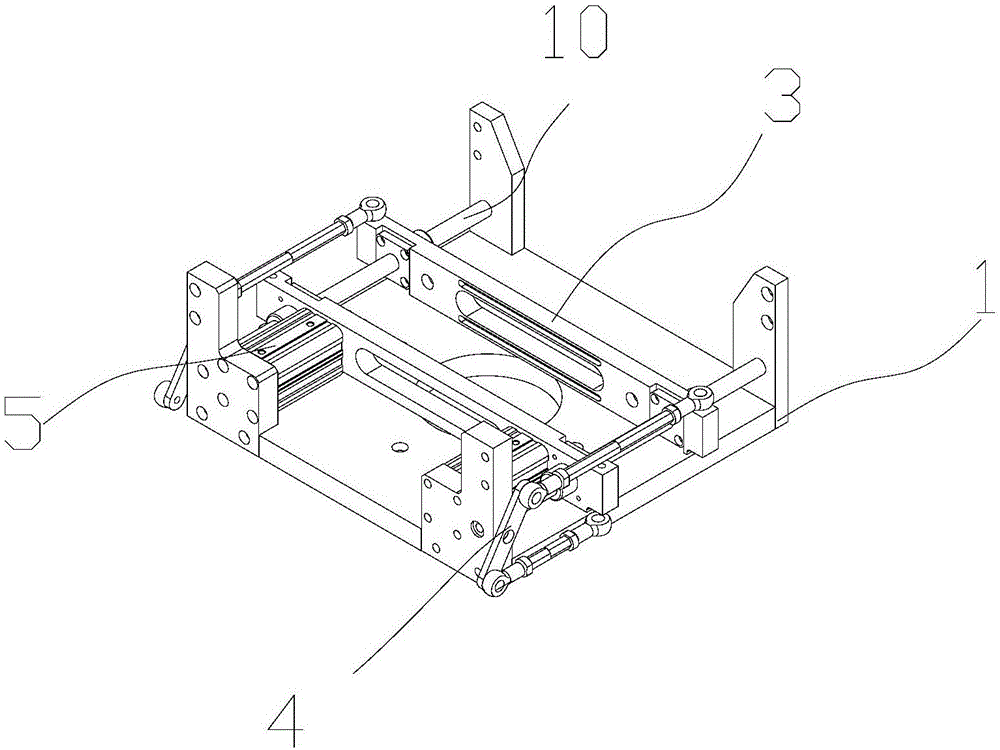

[0030] combine figure 1 As shown, the horizontal seal clamping mechanism of this embodiment includes a support frame 1, two splints 3, two swing bar mechanisms 4 and two splint drive members 5:

[0031] The support frame 1 is provided with a guide rail mechanism 10, and the two splints 3 are movably mounted on the guide rail mechanism 10 respectively, and can slide along the guide rail mechanism 10; sides.

[0032] The swing rod mechanism 4 includes three rods that are sequentially hingedly connected. The middle rod is pivotally installed on the support frame 1 to form a swing rod. It is arranged on the swing bar at the two sides of the pivot shaft, so as to realize the reverse linkage of the two splints 3 on the guide rail mechanism 10 .

[0033] The splint driver 5 is a linear cylinder fixed on the support frame 1, the piston rod of the linear cylinder is pushed in a direction parallel to the extension direction of the guide rail mechanism 10, and the piston rod is connect...

Embodiment 2

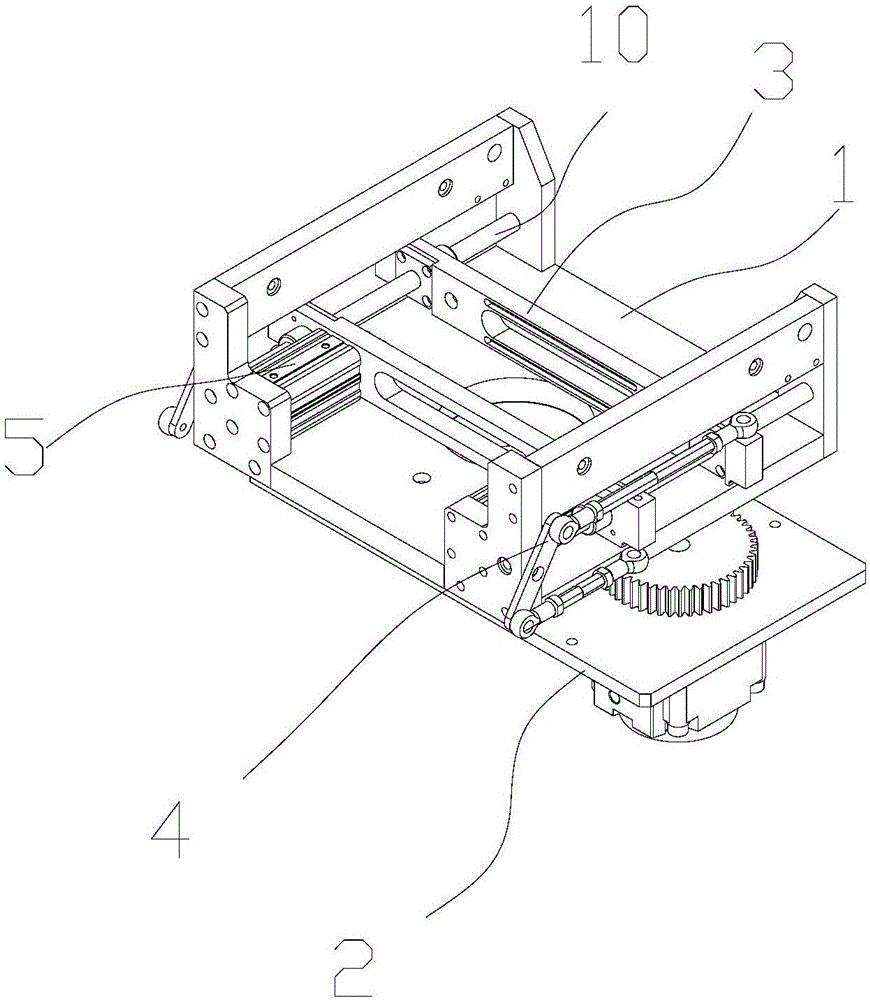

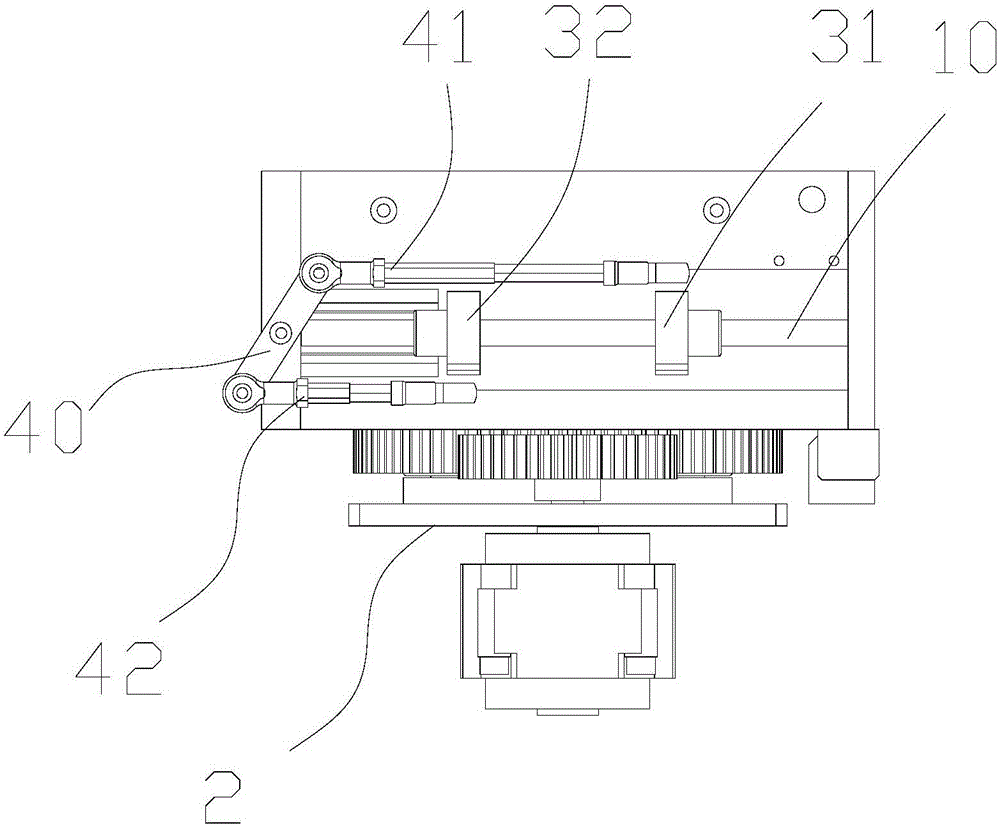

[0037] combine Figure 2 to Figure 4 , this embodiment is basically the same as Embodiment 1, the horizontal sealing clamping mechanism includes:

[0038] A support frame 1, the support frame 1 is provided with a guide rail mechanism 10; two splints 3, the two splints 3 are movably mounted on the guide rail mechanism 10, and can slide along the guide rail mechanism 10; , respectively arranged on both sides of the two splints 3; two splint driving parts 5, in order to realize the driving of the two splints 3.

[0039] In this embodiment, the swing link mechanism 4 includes a first pull rod 41 , a swing rod 40 , and a second pull rod 42 that are sequentially hingedly connected. On the support frame 1, the first pull rod 41 and the second pull rod 42 are respectively hinged to the two ends of the swing rod 40 to realize the reverse linkage of the first pull rod 41 and the second pull rod 42; then, the first pull rod 41 The pull rod 41 and the second pull rod 42 are hingedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com