Electroplating device for improving surface smoothness of electroplated part and continuous electroplating method thereof

A surface finish and electroplating device technology, applied in the direction of electrolytic components, electrolytic process, cells, etc., can solve problems such as unfavorable environmental protection, air pollution, poor electroplating environment, etc., achieve extremely high suction efficiency, high smoothness of plated parts, disassembly and replacement convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

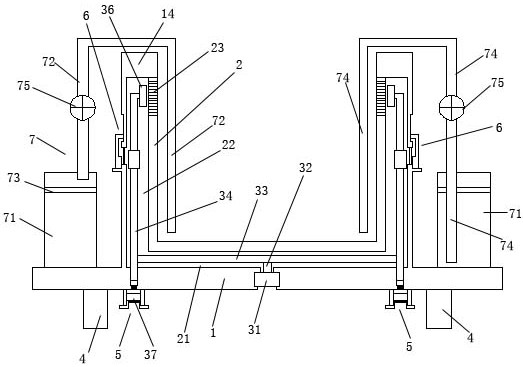

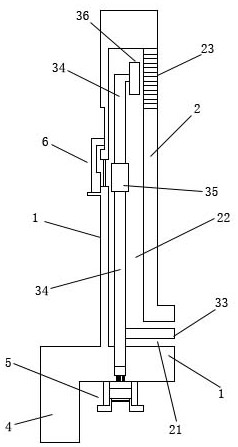

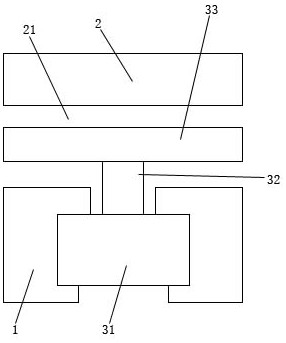

[0025] Such as Figures 1 to 6 As shown, an electroplating device for improving the surface finish of electroplated parts includes an internal electroplating chamber 2, an external support chamber 1, a support column 4, a rotary suction mechanism 3, and a plating solution circulation filter mechanism 7; the two external support chambers 1 A support column 4 is respectively installed at the lower end of the side; the inner electroplating bin 2 is installed on the inner upper side of the outer supporting bin 1; a ring clamp is formed between the outer side of the inner electroplating bin 2 and the inner side of the outer supporting bin 1. A wall cavity 22; a bottom cavity 21 is provided between the bottom of the internal electroplating warehouse 2 and the top of the external support warehouse 1; the surroundings of the bottom cavity 21 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com