Hoop clamp for hoop assembly

A technology of clamp clamps and clamps, which is used in hand-held tools, manufacturing tools, workpiece clamping devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

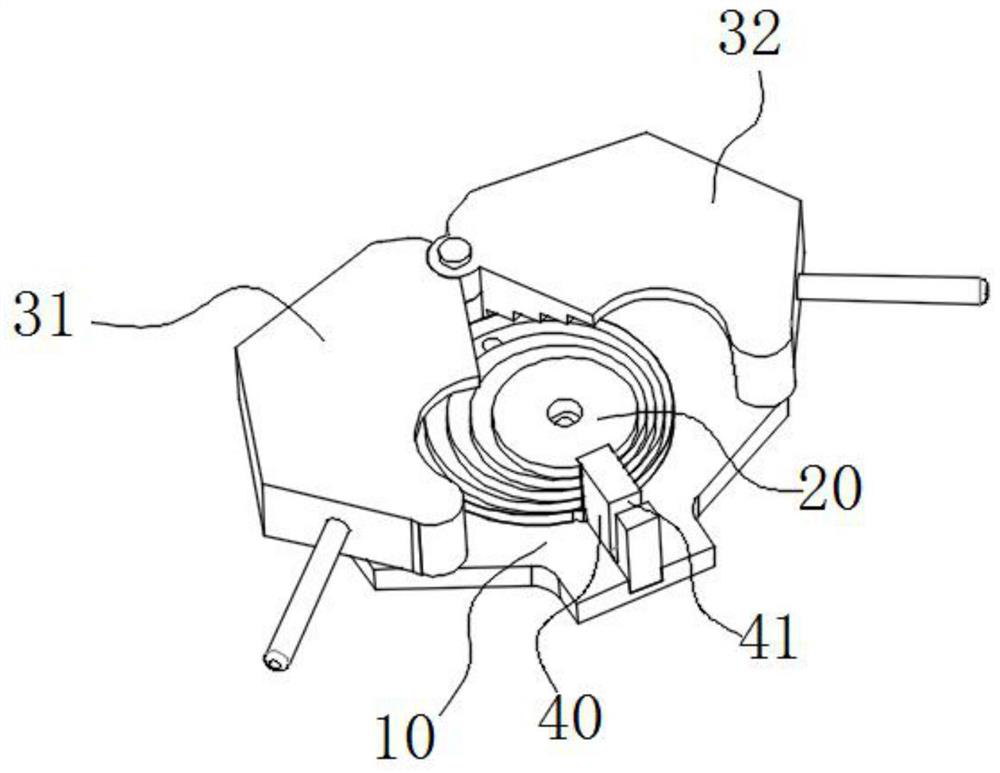

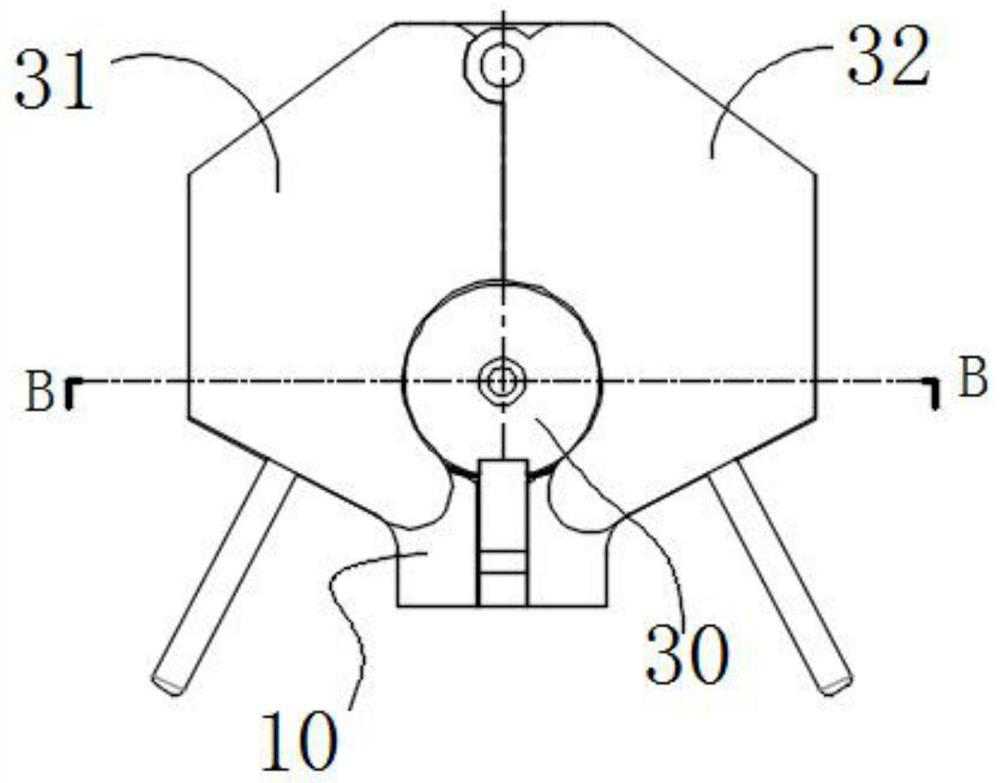

[0042] Embodiment 1: The first pliers body 31 and the second pliers body 32 are hinged to each other to form a hinge point, and the first pliers body 31 and the second pliers body 32 rotate relatively around the hinge point.

[0043] It can be understood that a rotating shaft is provided on the base plate 10, and rotating holes are respectively provided on the first pliers body 31 and the second pliers body 32, and the first pliers body 31 and the second pliers body 32 are both socketed through the rotating holes. On the rotating shaft, the hinge of the first pliers body 31 and the second pliers body 32 is realized; when the clamp band needs to be pressed together, the clamp band is first placed on the mold table, and then the first clamp body 31 and the second clamp body are rotated. The second pliers body 32 makes the two pliers bodies close to each other and slowly realizes the compression of the clamp band, so that the two ends of the clamp band are gradually approached.

Embodiment 2

[0044] Embodiment 2: The first pliers body 31 and the second pliers body 32 are arranged on the left and right sides of the core body 20 so that they can move linearly relative to each other, and driving parts are respectively arranged on the left and right sides of the core body 20 (not shown) to drive the first pliers 31 and the second pliers 32; under the action of the driver, the first pliers 31 on the left side of the core 20 move to the right, and the ones on the right side of the core 20 move to the right. The second pliers body 32 moves to the left, and the first pliers body 31 and the second pliers body 32 move relative to each other to realize the pressing of the band, so that the two ends of the band are close to each other.

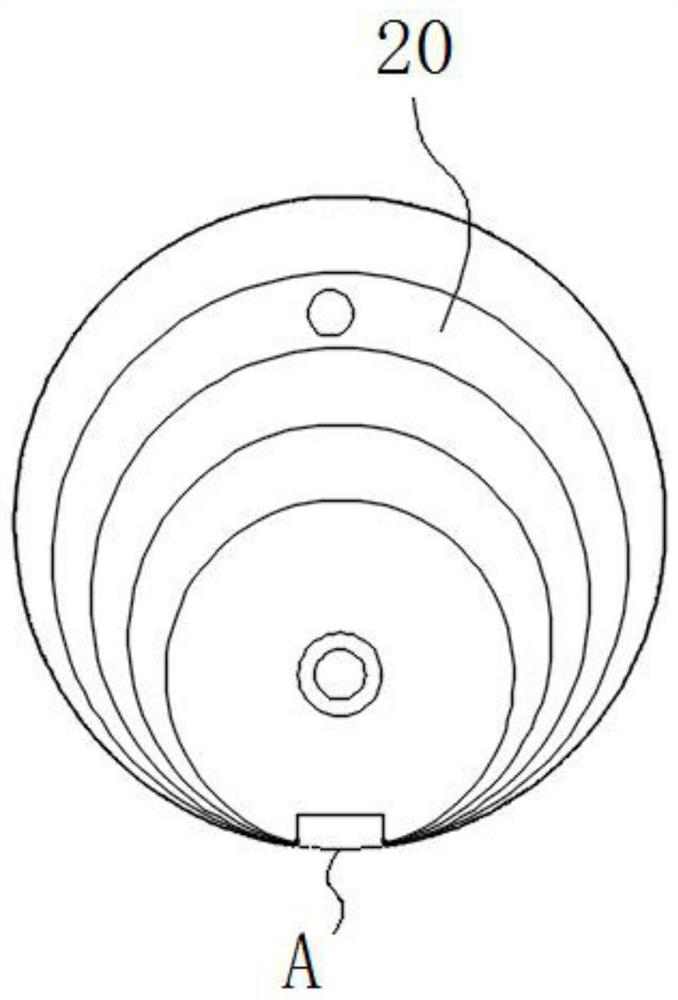

[0045] Optionally, an upwardly extending positioning block 40 is also provided on the base plate 10; a positioning notch 21 matching the positioning block is provided on the core 20 at a position directly opposite to point A; the core The body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com