Hot melting water segregator

A water separator and hot-melt technology, applied in the direction of pipeline connection layout, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of nut falling off, affecting the overall dust removal effect of the tube bundle type dust collector, and leakage of the water separator position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

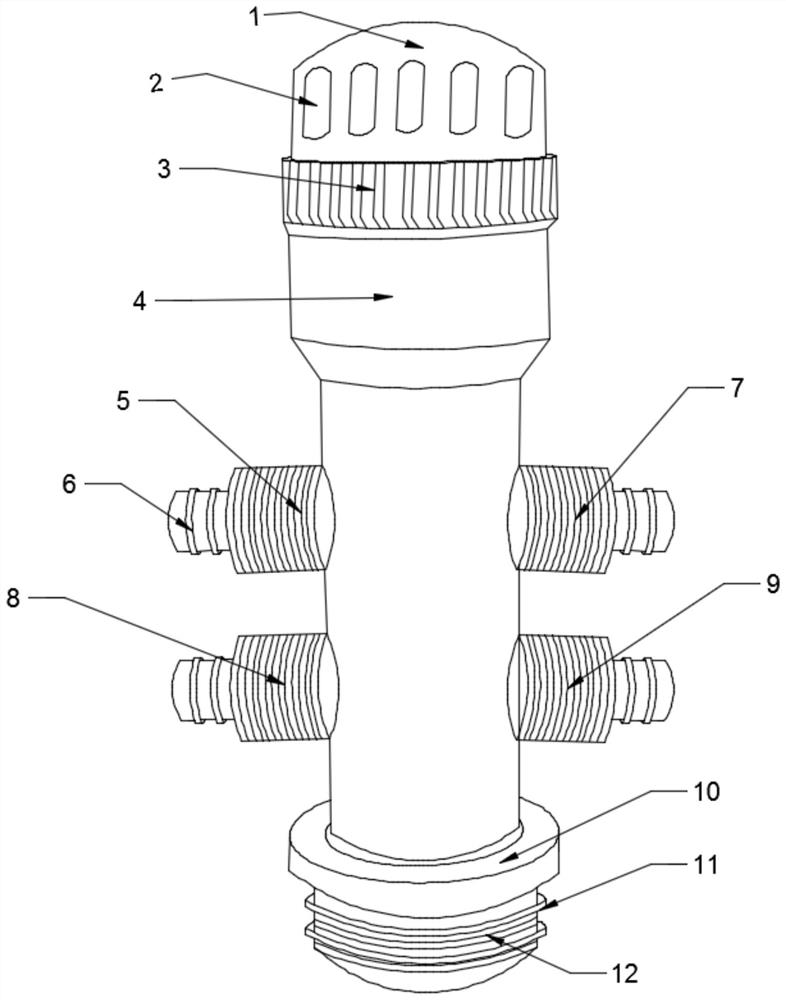

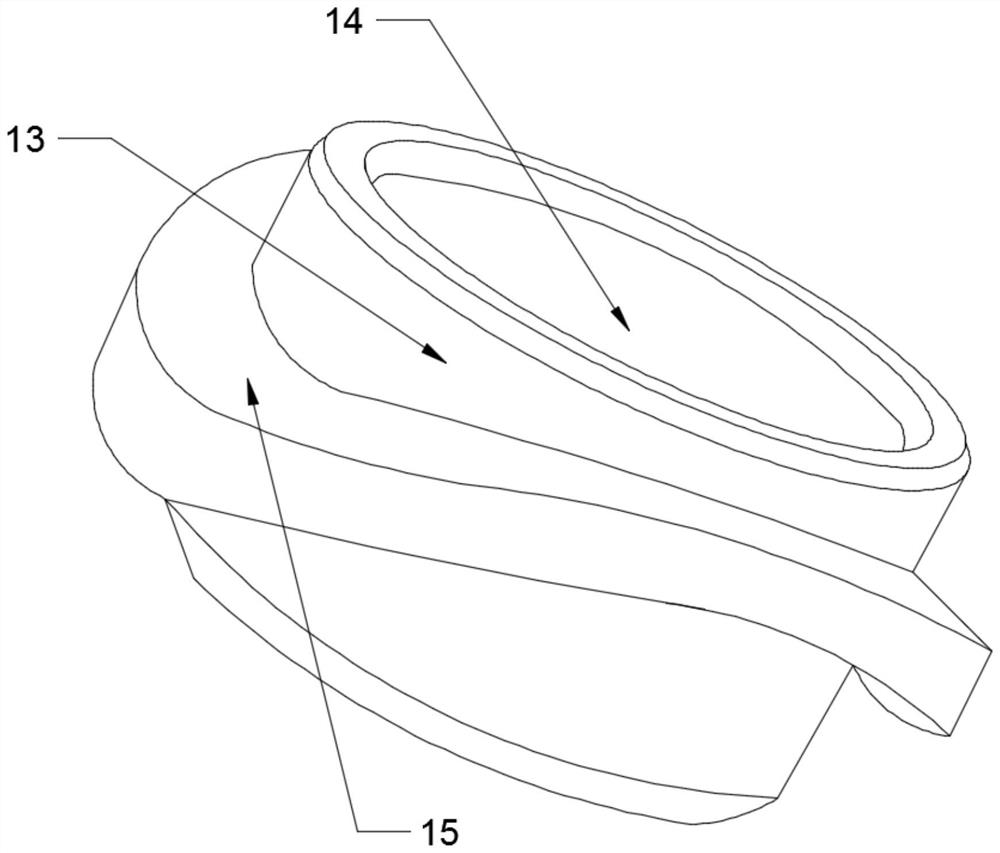

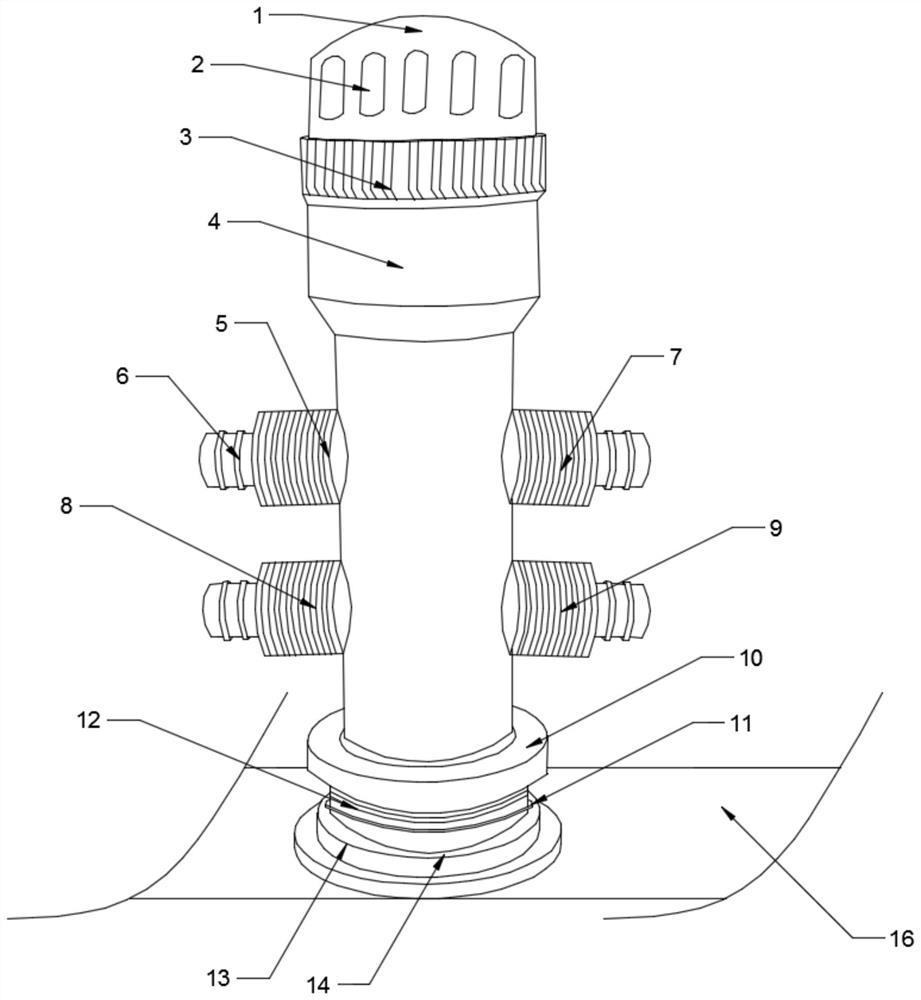

[0020] see figure 1 , figure 2 and image 3 , in an embodiment of the present invention, a hot-melt water separator, which includes: a water separator body 4 and a connecting seat 13, a threaded mounting hole 14 is opened inside the connecting seat 13, and a hot-melt plate is provided on the outside of the connecting seat 13 15. The lower end of the water separator body 4 is provided with an installation end 12, the outer surface of the installation end 12 is provided with a thread groove, and a large sealing gasket 11 is installed inside the thread groove outside the installation end 12;

[0021] When it is necessary to install the hot-melt water separator on the tube-bundle dust collector, the connecting seat 13 is hot-melted on the main water distribution pipe on the tube-bundle dust collector through automatic equipment in the factory, and then installed on the water separator After packing, it will be sent directly to the site. During on-site installation, the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com