A sound insulation wall panel preparation device

A technology for preparing devices and sound insulation walls, which is applied in construction, building components, metal processing, etc. It can solve the problems of wall panel cutting, shaking, and cumbersome fastening, and achieve the effects of preventing shaking, efficient noise reduction, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

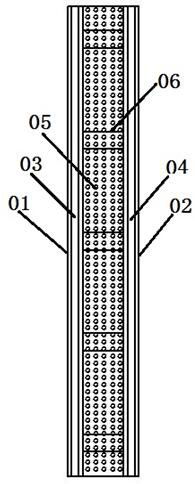

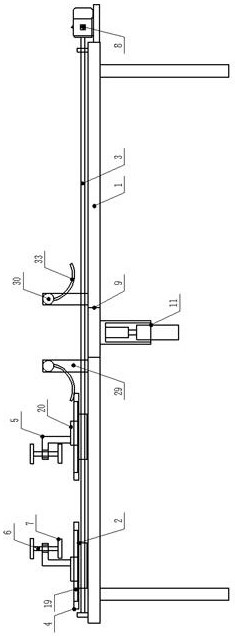

[0017] Example 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , a sound-insulating wall panel preparation device provided by the present invention is now described, the sound-insulating wall panel includes a first ply 01 and a second ply 02, the inner end of the first ply 01 is provided with a waterproof layer 03, the The inner end of the second board layer 02 is provided with a fireproof layer 04, and a sound-absorbing layer 05 is provided between the first board layer 01 and the second board layer 02, and the first board layer 01 and the second board layer Connecting cylinders 06 are evenly arranged between 02, the waterproof layer 03 is composed of organic emulsion and inorganic powder, the fireproof layer 04 is a composite ceramic material, and the sound-absorbing layer 05 is inorganic foam. The preparation device includes A processing table 1, the upper end of the processing table 1 is provided with a feeding mechanism 2, and the feeding me...

Embodiment 2

[0018] Example 2: see figure 2, a sound-insulating wall panel preparation device provided by the present invention is now described, the lower end of the processing table 1 is evenly provided with legs, the screw rods 3 are arranged along the length direction of the processing table 1, and the upper end of the processing table 1 And be positioned at the both sides of described screw mandrel 3 positions and be respectively horizontally spaced and be provided with guide rail in parallel, the quantity of described feeding seat 4 is two groups and all is evenly arranged on both sides of width direction of described processing table 1 upper end respectively, and described feeding seat 4 are arranged along the length direction of the screw mandrel 3, and guide grooves are respectively opened on both sides of the width direction of the lower end of the feeding seat 4 and corresponding to the positions of the guide rails. Connecting components are respectively provided, and the conne...

Embodiment 3

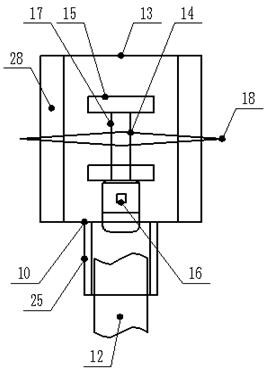

[0019] Embodiment 3: see figure 2 , image 3 , Figure 4 , Figure 5 Now, a description is given to a sound-insulating wall panel preparation device provided by the present invention. The rectangular opening 9 is opened along the width direction of the processing table 1, and the first telescopic frame 11 and the second telescopic frame 15 are composed of hollow fixing frames, One end is movably inserted into the hollow fixed frame, and the movable frame is composed of a telescopic cylinder provided between the insertion end of the movable frame and the inner end wall of the hollow fixed frame. The fixed ends of the first telescopic frame 11 are respectively connected to the lower end of the processing table 1 The middle side of the telescopic end end of the first telescopic frame 11 vertically downward and along the vertical direction are respectively provided with positioning bayonets 21, and the outer wall of the telescopic end side of the first telescopic frame 11 corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com