Needle pressing mechanism of stringer, stringer and pressing method thereof

A technology of string welding machine and needle bar, which is applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of limited pressing amount, low life and wear of contact surface of welding mechanism, so as to avoid false welding and weakening. The effect of impact and interference avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

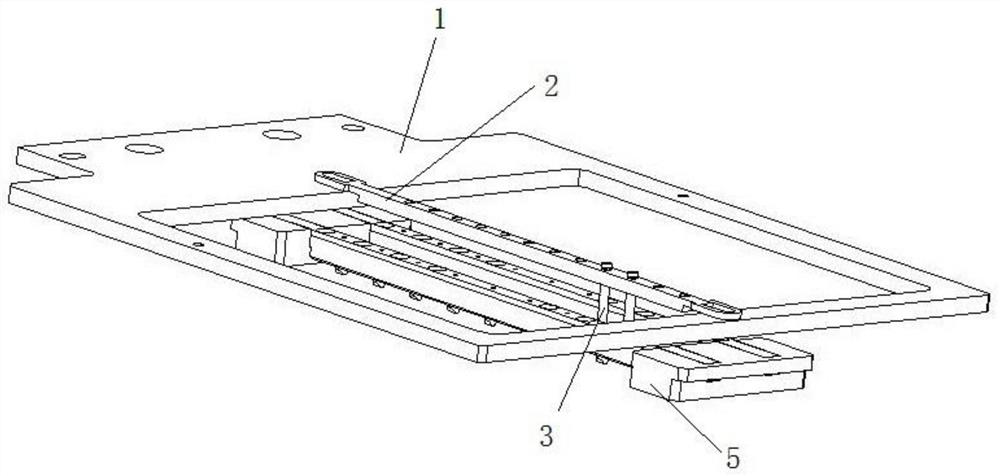

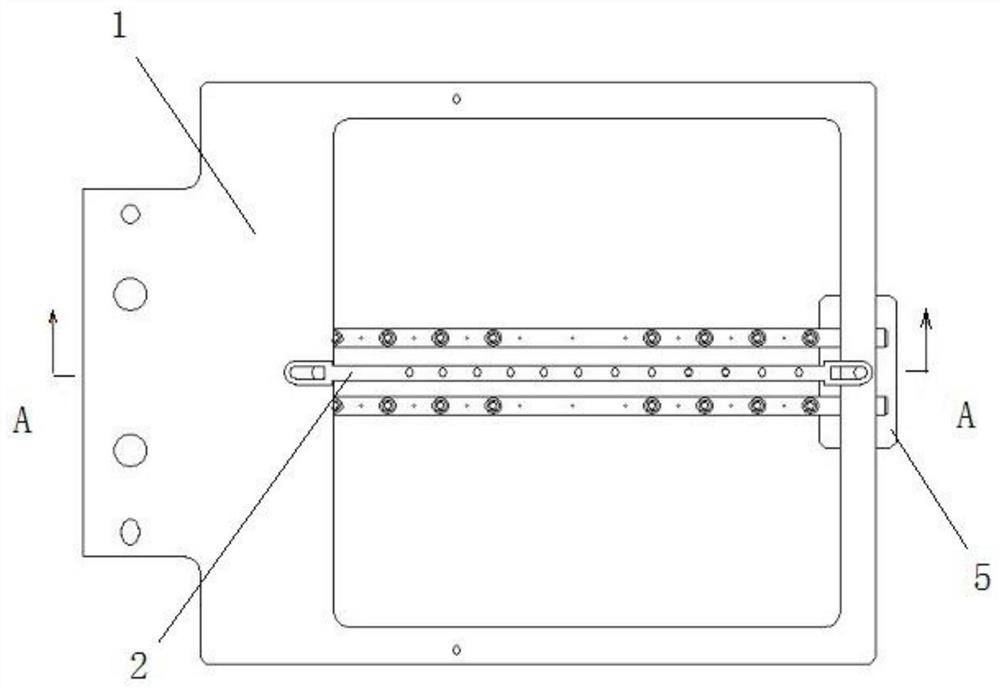

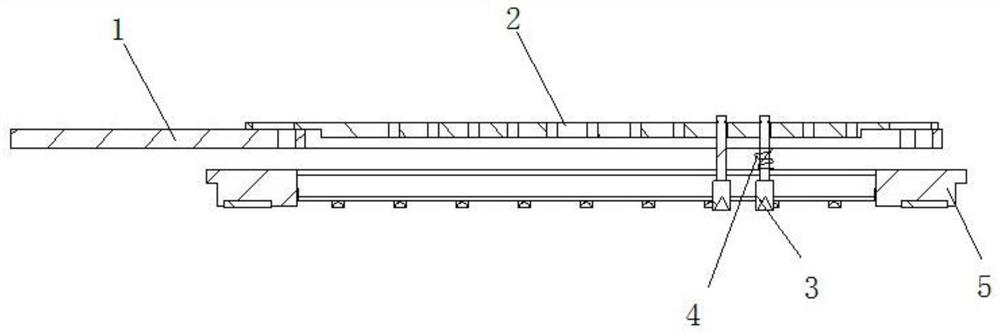

[0044] The invention provides a needle pressing mechanism of a stringer welding machine, such as Figure 1-10 As shown, it includes: pressure needle bar support 1, pressure needle bar 2, pressure needle 3, spring 4 and welding ribbon press net 5; wherein, the stringer welder uses welding belt press net 5 to press the welding ribbon, and welding ribbon press net 5 It is set above the welding ribbon to press the welding ribbon to prevent the ribbon from shifting during the welding process of the battery sheet; the pressure pin 3 is used to provide downward pressure to compress the welding ribbon to ensure that the battery sheet is welded into a battery string through the welding ribbon During the process, there will be no false welding phenomenon, which ensures the welding quality of the stringer. The spring 4 is arranged between the indenter 3 and the indenter bar 2, and is used for buffering the impact of the indenter 3 on the welding ribbon. After the spring 4 is compressed, ...

Embodiment 2

[0074] A stringer, using the stringer mechanism in Embodiment 1 to press the ribbon.

Embodiment 3

[0076] A method for compressing the welding strip of a stringer, characterized in that the needle pressing mechanism of the stringer according to Embodiment 1 is adopted, comprising the following steps:

[0077] Step S1: Rotate the second cylinder (322) to move up or down relative to the first cylinder (321), and adjust the length of the pressing needle (3);

[0078] Step S2: the pressing needle (2) moves down to drive the pressing needle (3) to move downward, and the pressing needle (3) contacts the welding strip;

[0079] Step S3: Continue to move down the needle bar (2) to compress the spring (4).

[0080] Before adjusting the length of the indenter 3, install the indenter 3 on the indenter bar 2. Specifically, the installation method of the indenter 3 on the indenter bar 2 is:

[0081] First, the spring 4 is sleeved on the outside of the pressing needle body 32;

[0082] Furthermore, the indenter main body 32 is inserted into the indenter installation hole 24 from below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com