Automatic tube taking and labeling device for vein blood sampling

A labeling and automatic technology, applied in the directions of labeling, labeling machine, transportation and packaging, etc., can solve the problems of wrong tube taking or labeling, high labor cost, low work efficiency, etc., to achieve accurate tube taking, reduce labor costs, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

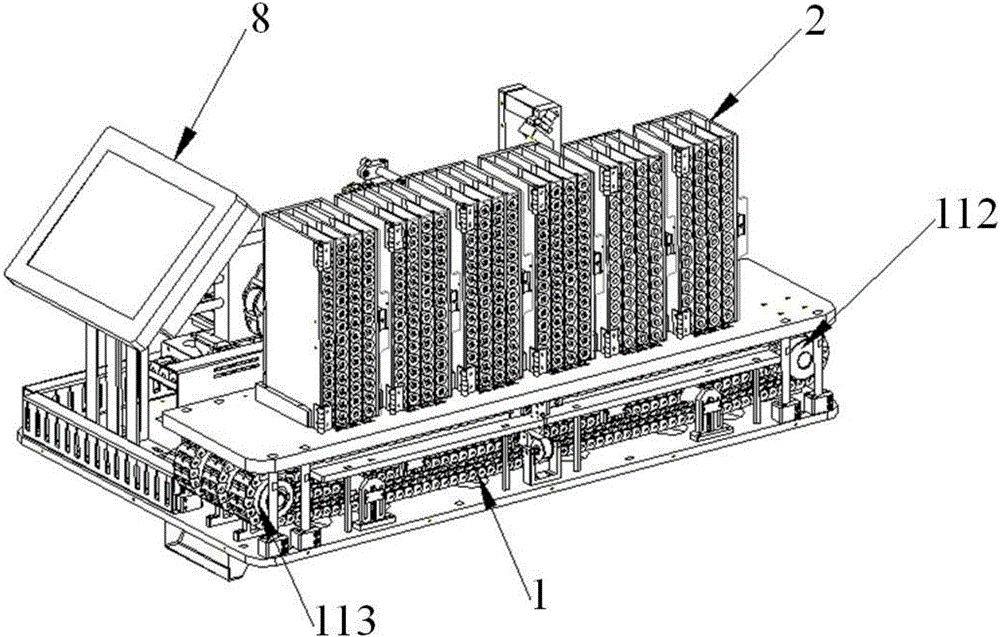

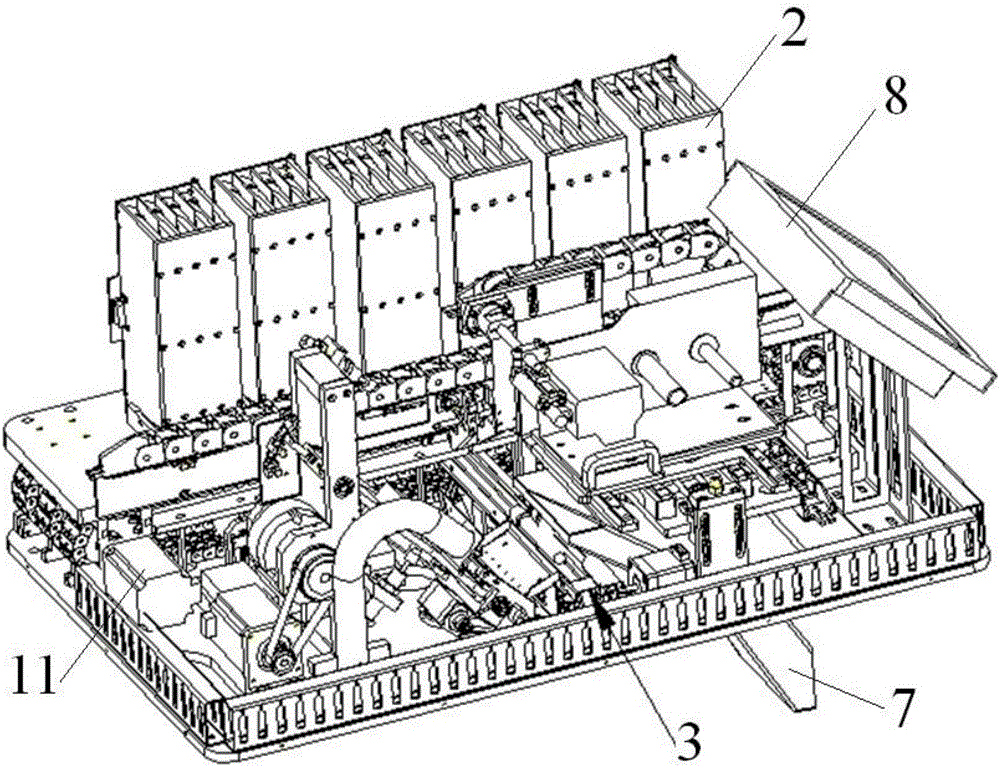

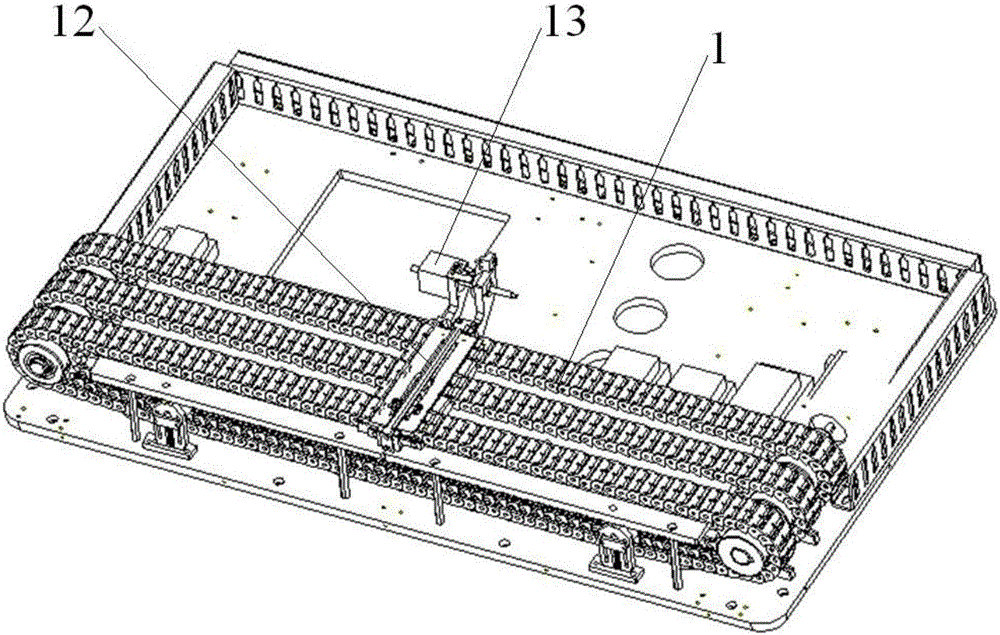

[0034] This example is used for automatic tube taking device for venous blood collection, such as Figure 1 to Figure 11 As shown, it includes a conveyor belt 1, a test tube box group 2, a tube feeding mechanism 3, a manipulator 4, a marking mechanism 5, a printer 6 and a test tube outlet assembly 7. The conveyor belt 1 is driven and transported by an independent conveyor belt drive device 11, such as image 3As shown, the conveyor belt driving device 11 is an electric motor, and the two ends of the conveyor belt 1 are provided with a drive wheel set, the drive wheel set includes a driving wheel 112 and a driven wheel 113, and the rotor of the electric motor is connected to the driving wheel 112 to drive the conveyor belt 1 to rotate; the conveyor belt 1 Be a plastic chain or a belt, and this example specifically adopts a plastic chain. The conveyor belt 1 is provided with a test tube groove 12 with a switchable door up and down, such as Figure 4 As shown, the opening of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com