Multi-stage flow control structure

A technology of flow control and concave structure, which is applied in the direction of capping with auxiliary devices, packaging, sealing parts with unloading devices, etc., which can solve the problems of waste of liquid materials, inconvenient use, and need for cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

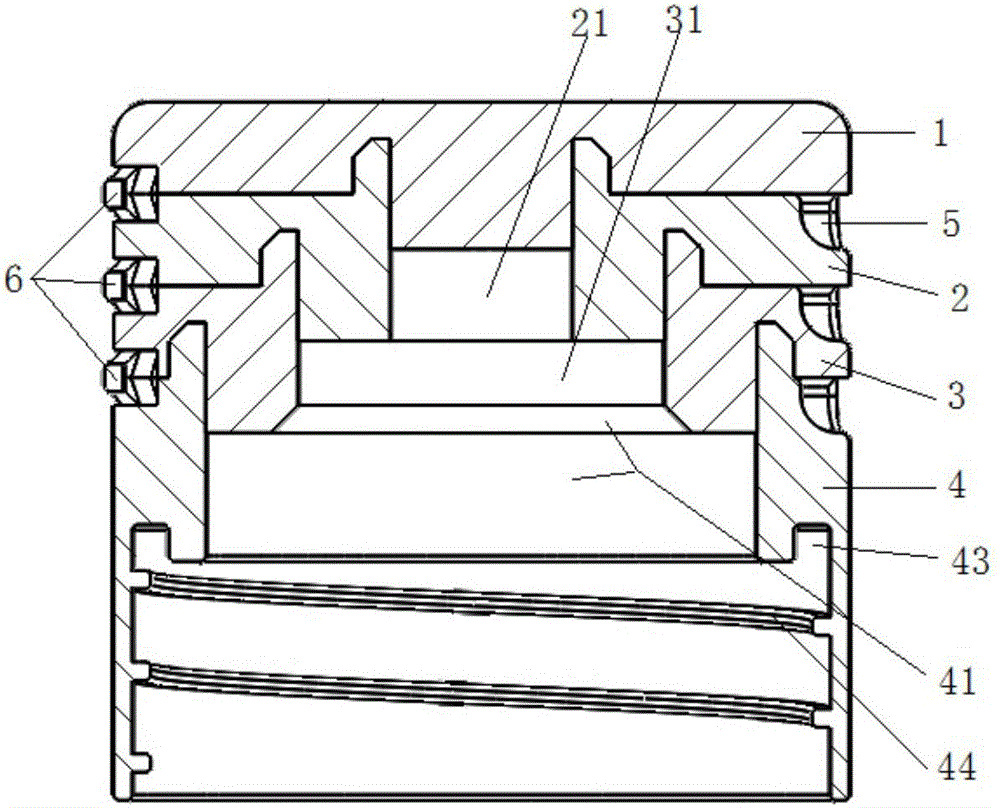

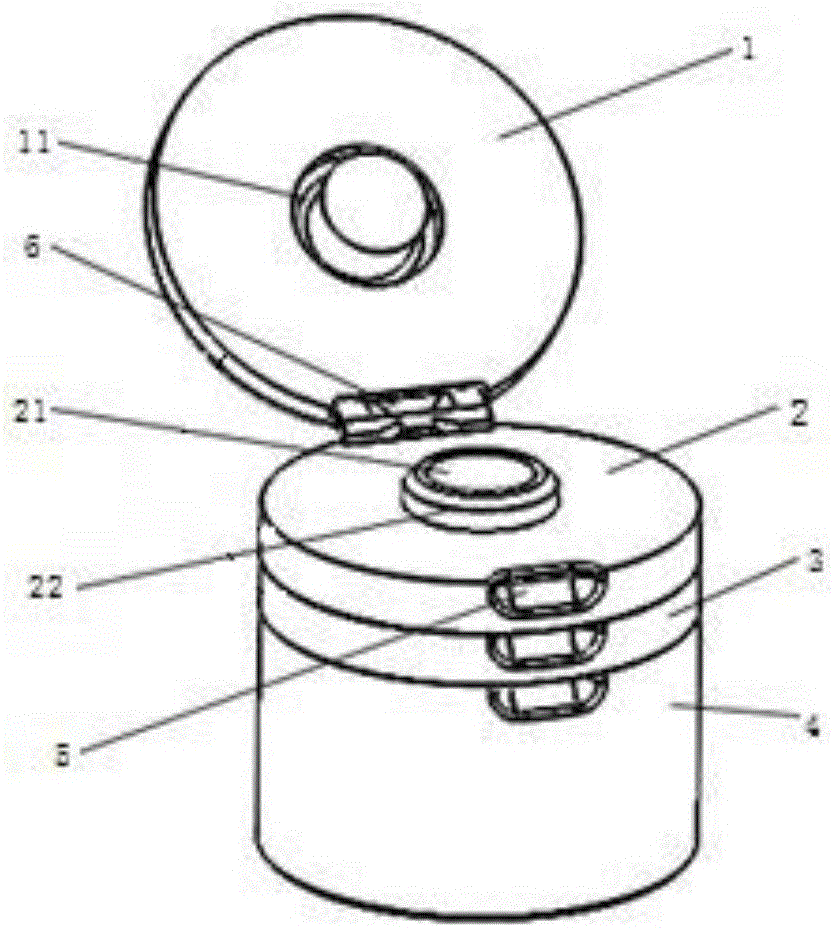

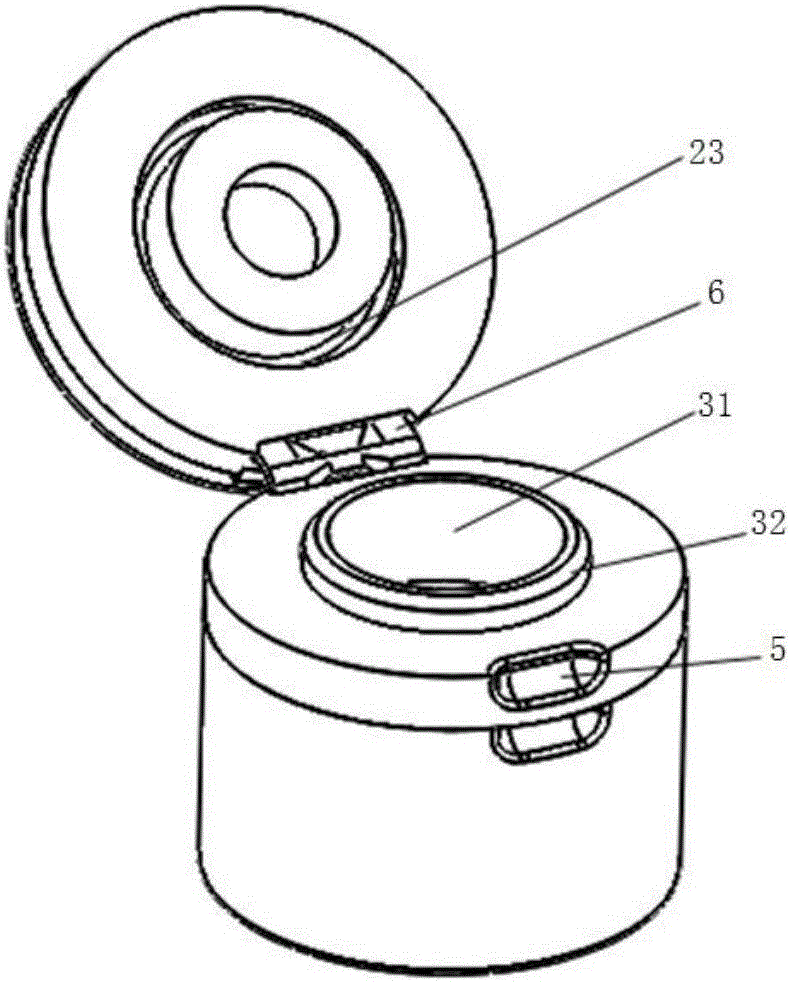

[0025] The invention provides a multi-stage flow control structure, and in particular relates to a container cover provided with multiple flow control layers, or a container including the container cover.

[0026] A multi-stage flow control structure provided by the present invention includes a cover plate and a multi-stage flow control layer;

[0027] The cover plate is socketed on the flow control layer;

[0028] The flow control layers at all levels of layer-by-layer sockets are equipped with limited flow ports;

[0029] The arrangement order of the calibers of the restrictors is as follows: they are arranged in order from small to large according to the direction in which the vertical distance between the flow control layer where they are located and the cover plate increases.

[0030] Further, the multi-stage flow control structure also includes: a connecting piece;

[0031] The connecting piece is arranged between the cover plate and the flow control layers of each lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com