Storage tank oil and gas recovery safety control system and control method

A safety control and storage tank technology, which is applied in the field of oil and gas recovery in storage tanks, can solve the problems of unreliable detection and control of oxygen content in the system, difficulty in ensuring safety, imperfect oil and gas recovery process and explosion-proof performance of storage tanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

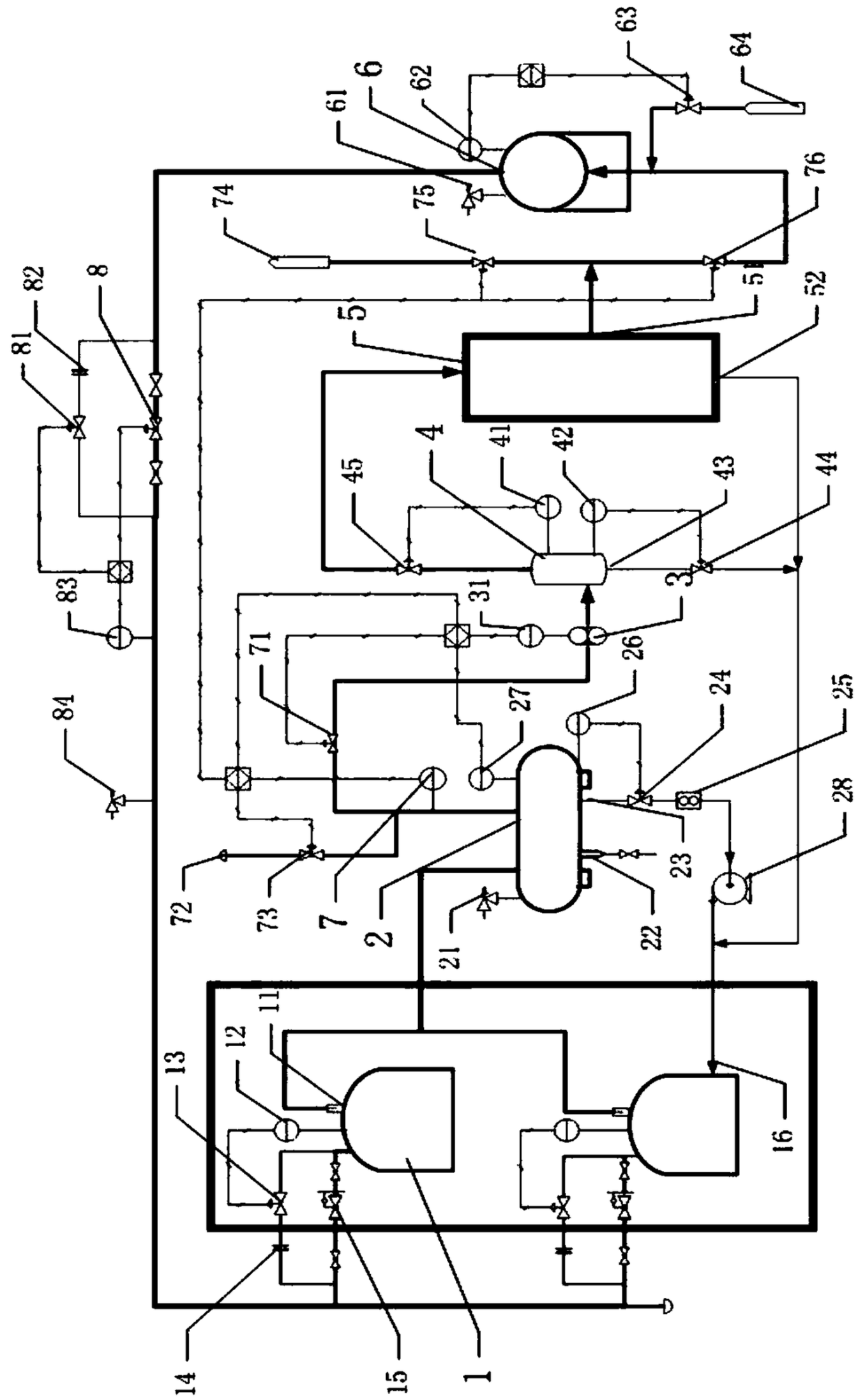

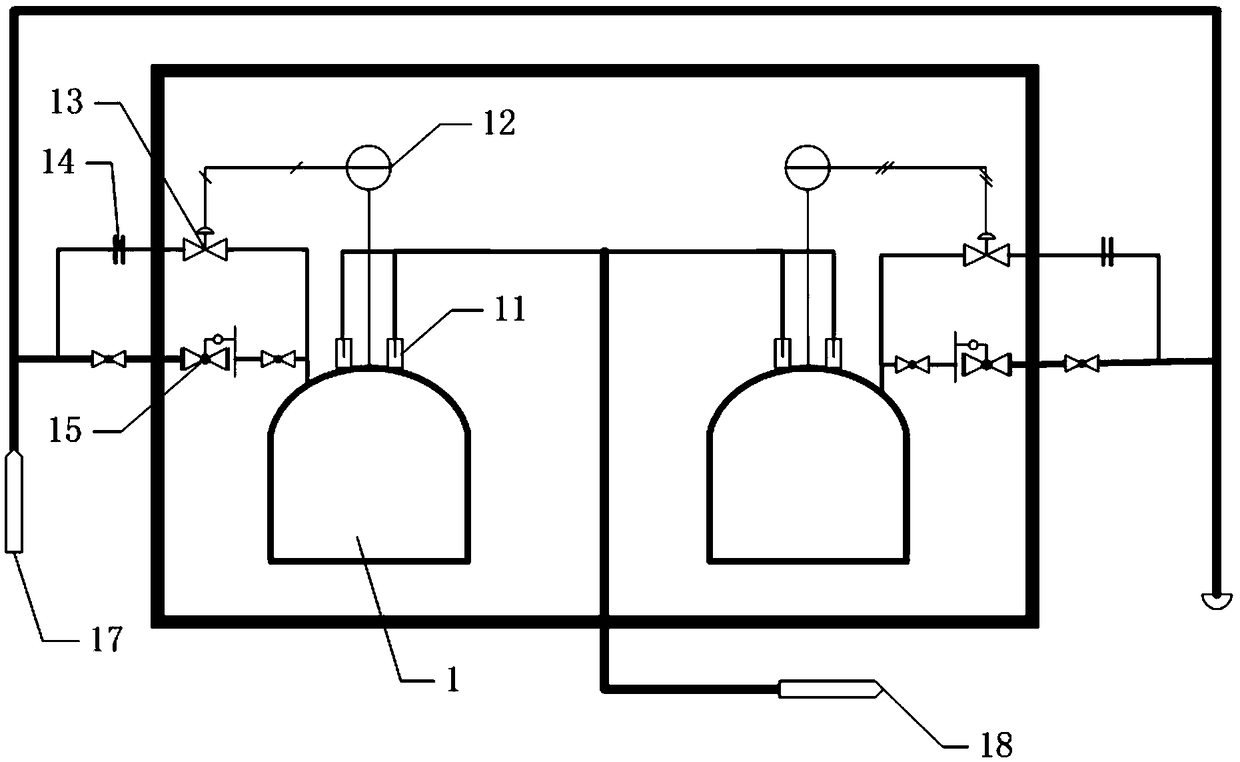

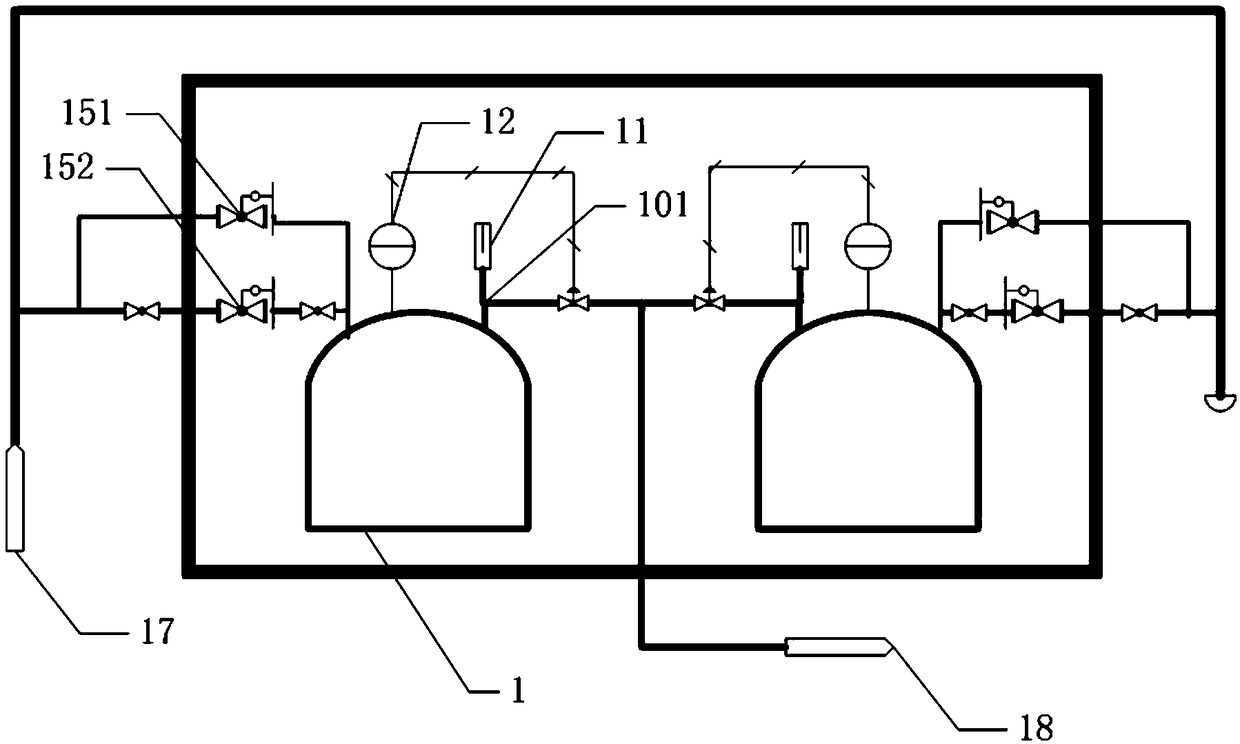

Embodiment 1

[0069] figure 1 The schematic diagram of the process flow of the storage tank oil and gas recovery safety control system provided by the embodiment of the present invention, as shown in figure 1 As shown, the present embodiment provides a storage tank oil and gas recovery safety control system, including a storage tank 1, a liquid separation tank 2, a compressor 3, a separation tank 4, an oil and gas recovery device 5, and a buffer tank 6; The mouth is connected with the air inlet of the liquid separation tank 2, the air outlet of the liquid separation tank 2 is connected with the compressor 3, the compressor 3 is connected with the air inlet of the separation tank 4, and the air outlet of the separation tank 4 is connected with the oil vapor recovery device 5 The inlet is connected, the outlet of the oil and gas recovery device 5 is connected to the buffer tank 6, and the buffer tank 6 is connected to the suction port of the storage tank 1; an oil and gas regulating valve 71 ...

Embodiment 2

[0087] Such as figure 1 As shown, this embodiment provides a control method for a storage tank oil and gas recovery safety control system, including:

[0088] (1) System oxygen content control method:

[0089] The oil gas exhaled from the exhalation port of the storage tank 1 enters the liquid separation tank 2, and the gas separated by the liquid separation tank 2 enters the separation tank 4 after being compressed by the compressor 3, and the gas separated by the separation tank 4 is recovered by oil and gas The device 5 purifies the oil and gas, and the purified oil and gas enters the buffer tank 6, and the gas in the buffer tank 6 enters the storage tank 1 as the breathing source of the storage tank 1 through the suction port of the storage tank 1, forming a closed circulation system; According to the explosion limit of the oil and gas components in the storage tank 1, set the risk value and control value of the oxygen content in the system; adjust the limit system throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com