Screw arranging and conveying device

A conveying equipment and screw technology, which is applied in the field of screw arrangement and conveying equipment, can solve the problems of high manufacturing cost, difficult installation and debugging, and low precision of material distribution position, and achieve simplified structure, reduced installation and debugging difficulty and manufacturing cost, and improved The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

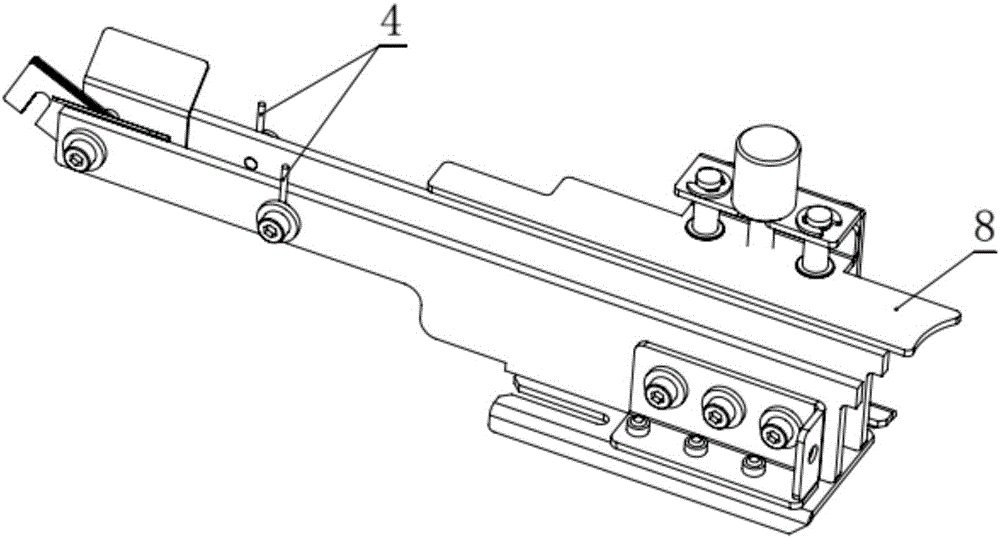

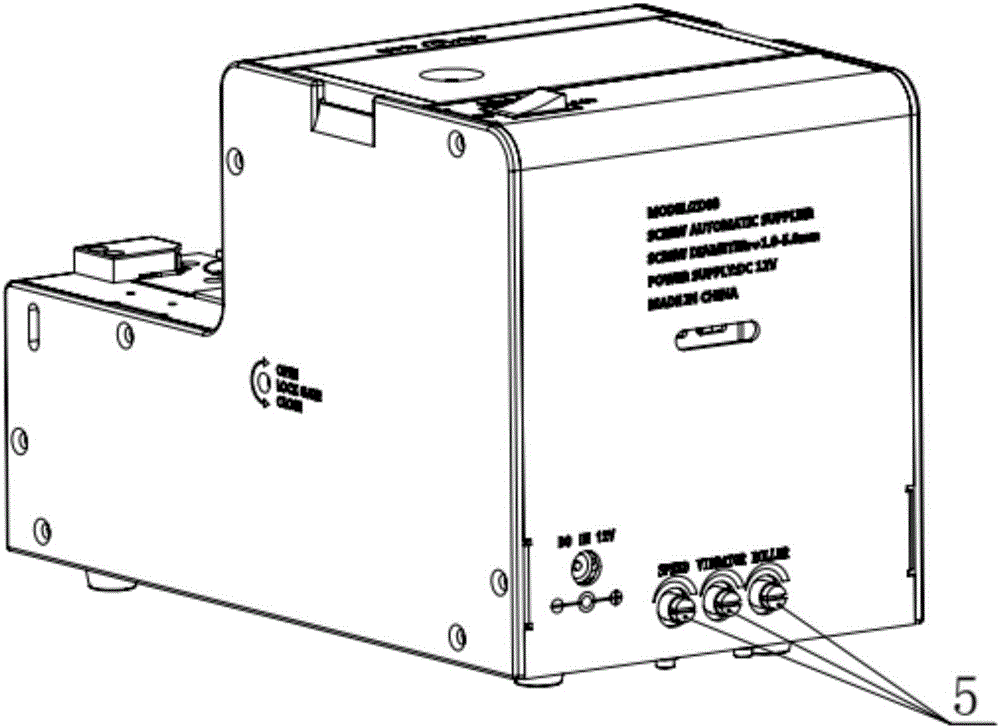

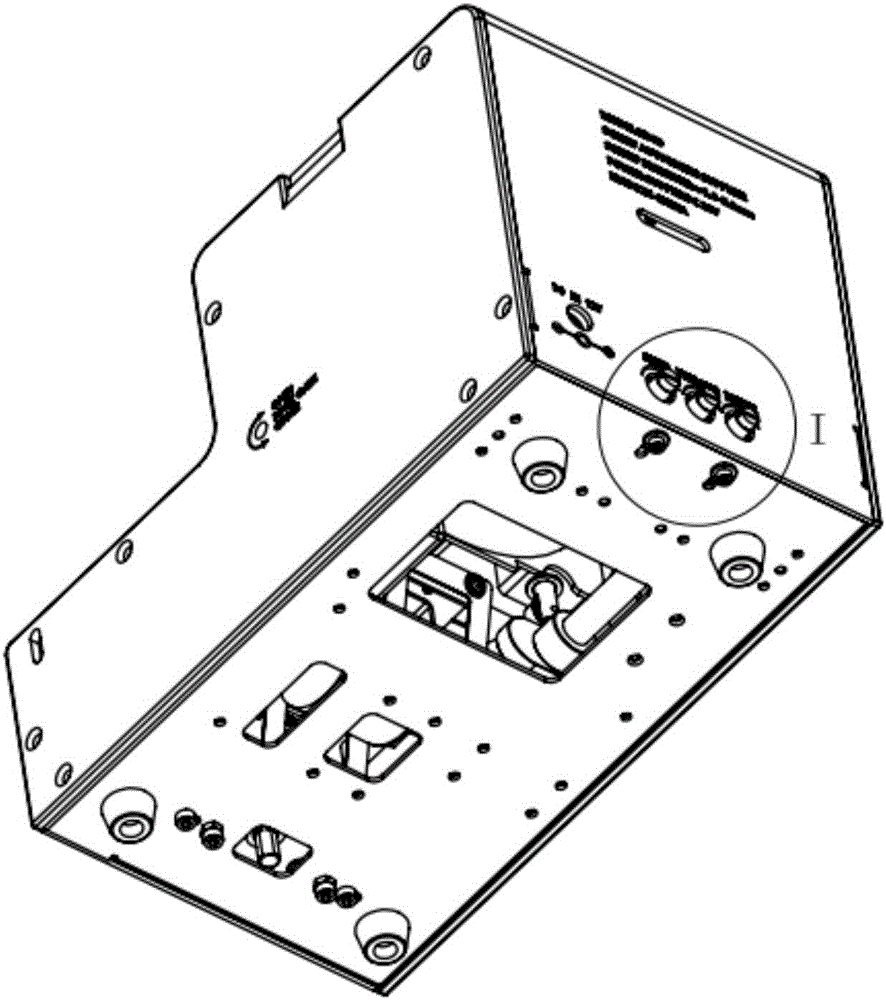

[0026] A screw arrangement and conveying equipment, including a material storage chamber 1, a conveying track 2, a distributor turntable 3, a drive mechanism capable of driving the turntable to rotate, and a control mechanism that controls the drive of the drive mechanism. Inside, the other end is connected with the distributor turntable 3, such as figure 1 As shown, both sides of the conveying track are provided with screw attitude adjustment columns 4, and the control mechanism includes an adjustment knob 5 for adjusting driving parameters, such as figure 2 As shown, the adjustment knob 5 is arranged on the rear side of the material chamber 1, and the control mechanism also includes a photoelectric switch assembly that controls the rotation or stop of the distributor turntable 3. The photoelectric switch assembly includes a light emitter, and a photoelectric sensor with a sensing signal gap sheet 6 and a photoreceiver corresponding to the light emitter, such as Figure 7 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com