Paper feeding device of die cutting machine

A technology of paper feeding device and die-cutting machine, which is applied in the directions of transportation and packaging, thin material handling, and separation of objects, etc., can solve the problems of being easily taken away by the paper-pushing claw, deviating from the cutting track of the die-cutting machine, and separating the cardboard, etc. The effect of saving resources, ensuring cutting quality and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

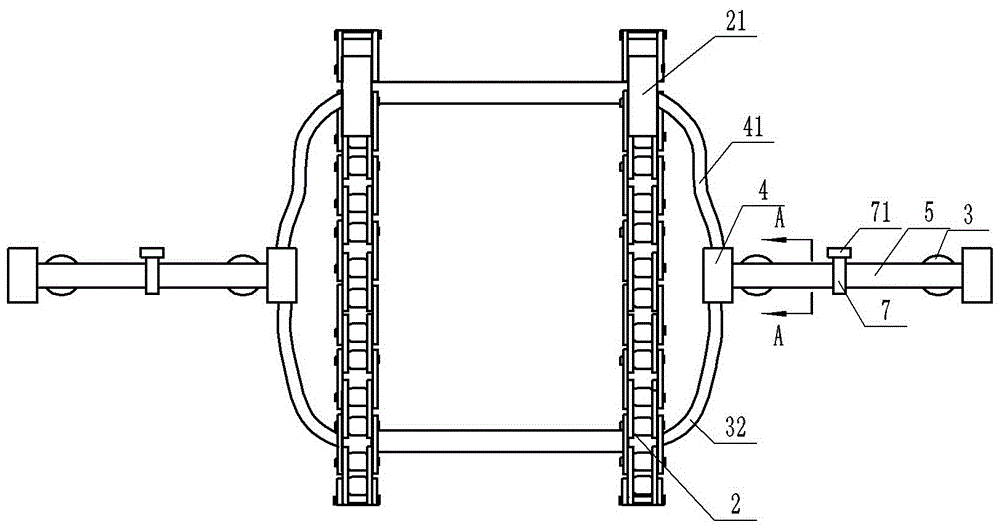

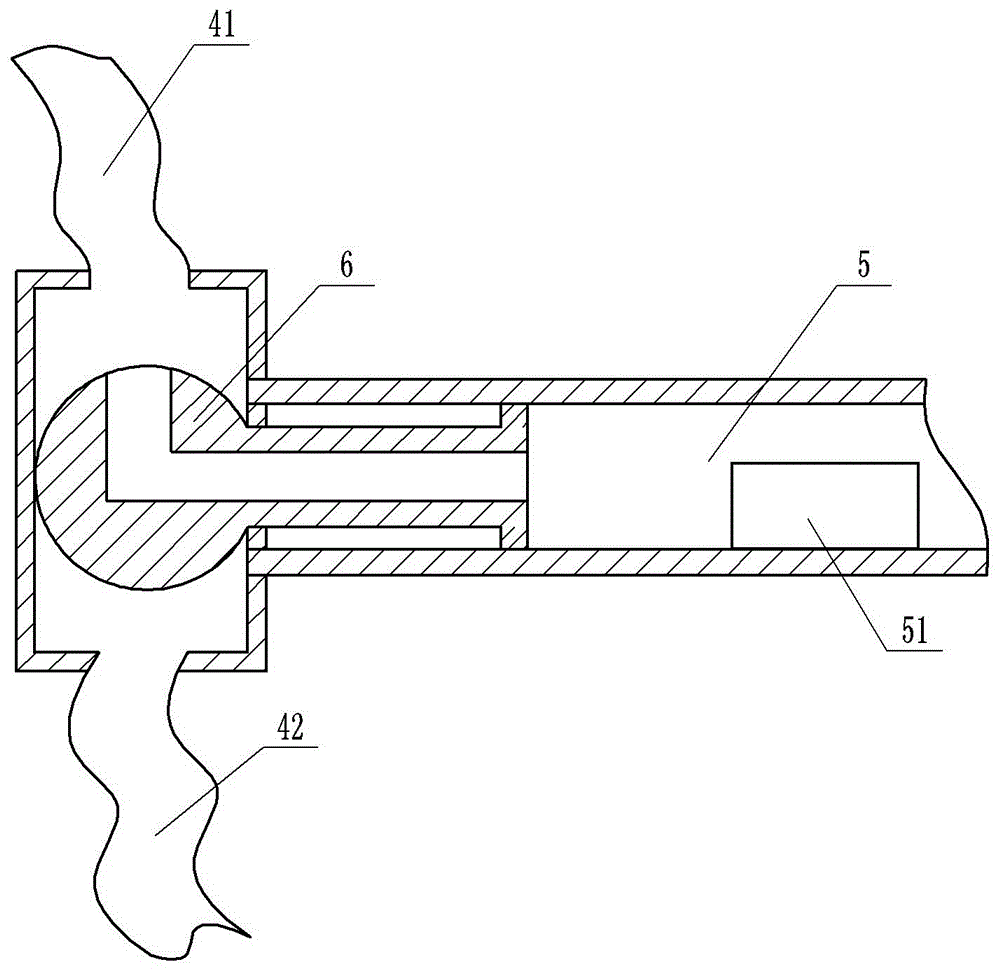

[0020] The reference numerals in the drawings of the specification include: sprocket 1, chain 2, first paper push claw 21, second paper push claw 22, first clamping plate 23, second clamping plate 24, groove 25, air bag 26. Spring 27, limit block 28, suction nozzle 3, rotating sleeve 4, first pipe 41, second pipe 42, rigid pipe 5, air extraction device 51, valve core 6, solenoid valve 7, solenoid valve controller 71 .

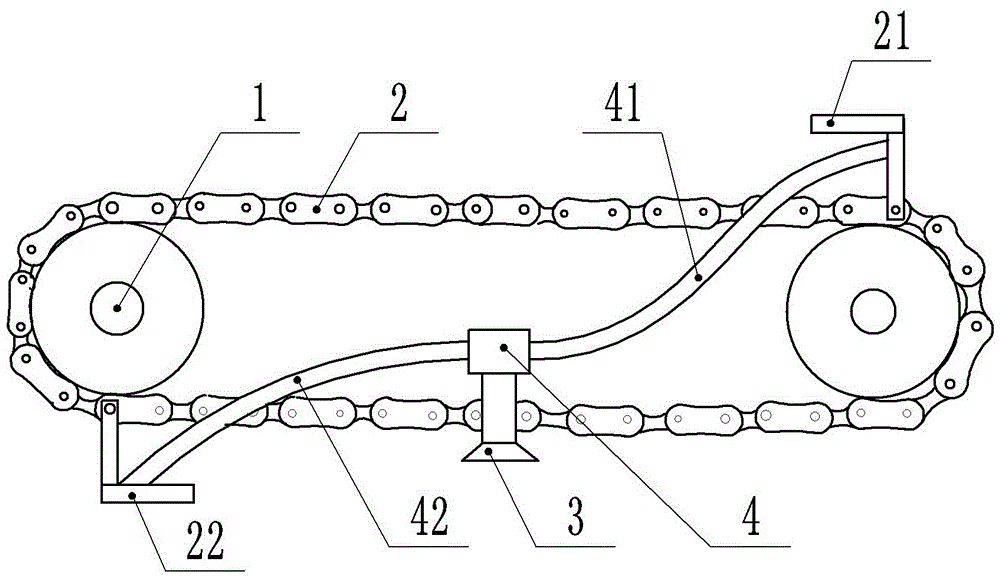

[0021] Such as figure 1 , figure 2 As shown, a paper feeding device of a die-cutting machine includes two symmetrically arranged paper feeding units, one paper feeding unit includes a rigid pipe 5, two suction nozzles 3, a first paper pushing claw 21, and a second paper pushing claw 22 , chain 2 and two sprockets 1, the chain 2 is set on the two sprockets 1 and meshed with the two sprockets 1; the first paper pushing claw 21 and the second paper pushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com