Feedstuff lifting device

A technology of feed raw materials and elevators, applied in transportation and packaging, elevators in buildings, etc., can solve the problems of material tray bruises, loud noise in the production workshop, and accidents caused by falling buildings, and achieve the effect of improving the safety system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

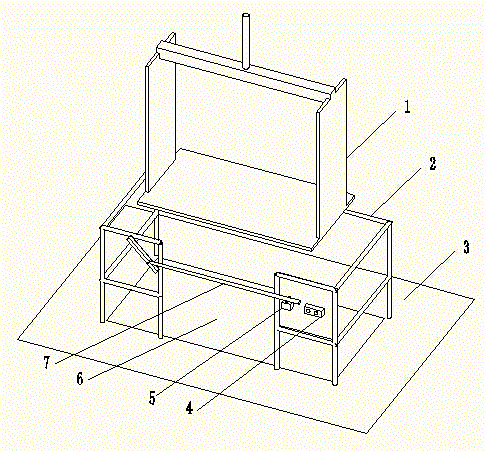

[0007] The present invention is described in further detail in conjunction with accompanying drawing, below hoist hangs with material tray 1, and material tray 1 can move up and down in the lifting port 6 in guardrail 2, is fixed on the guardrail 2 on the floor 3 and has loading and unloading opening, control The button switch 4 for the lifting of the hoist is fixed on the guardrail 2 next to the loading and unloading port, one end of the protective rod 7 is hinged on the guardrail 2 on the side of the loading and unloading port, and the other end of the protective rod 7 is placed on the travel switch 5, and the travel switch 5 is used Screws are fixed on the guardrail 2 on the other side of the loading and unloading port, and the travel switch 5 is the power control switch of the hoist.

[0008] Because different floors use the same hoist, after the present invention is installed on different floors, no matter which floor wants to use the hoist, as long as the protective bar i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com