A deep eutectic solvent microemulsion extraction system and method for extracting astaxanthin

A deep eutectic solvent and microemulsion technology, applied in organic chemistry and other directions, can solve the problems of increasing the extraction process time, the recovery rate is only 66%, and it is not very mature, so as to protect the biological activity, shorten the extraction time, and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] In some embodiments, the preparation method of the deep eutectic solvent includes: mixing according to the molar ratio of each component, heating to a temperature of 70-90° C. until clear and transparent, and cooling to room temperature.

[0060] In some embodiments, the preparation method of the deep eutectic solvent microemulsion extraction system includes: mixing the components in proportion and stirring until uniform.

[0061] The present invention also provides a method for extracting astaxanthin with a deep eutectic solvent microemulsion extraction system, comprising the following operations:

[0062] Prepare deep eutectic solvent microemulsion extraction system;

[0063] adding shrimp shell powder to the deep eutectic solvent microemulsion extraction system, and reacting and extracting;

[0064] Separation of solid and liquid to obtain the supernatant, i.e. astaxanthin extract;

[0065] adding a stripping agent to the supernatant for stripping;

[0066] solid-...

Embodiment 1

[0076] Embodiment 1 Deep eutectic solvent microemulsion extraction system of the present invention

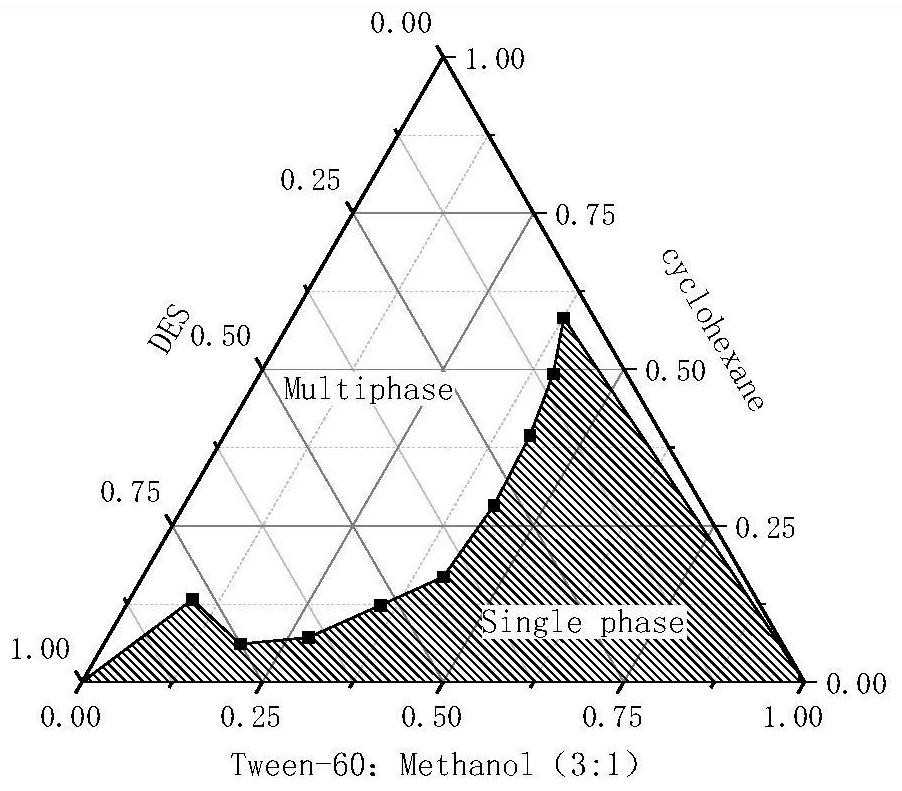

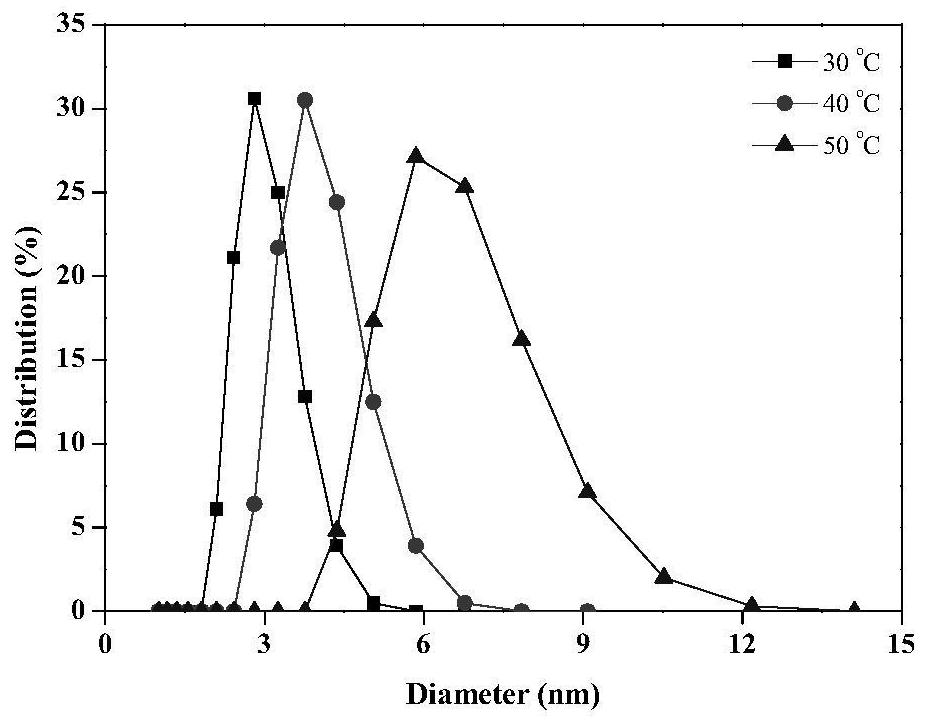

[0077] The deep eutectic solvent formed by lactic acid, glucose and water in a molar ratio of 5:1:3, Tween 60, methanol and cyclohexane were mixed according to different mass ratios, and their phases were observed at 30°C. For statistics of the results, see figure 1 , see particle size distribution figure 2 , the results show that the deep eutectic solvent microemulsion extraction system can be guaranteed to be a uniform microemulsion within the proportioning range of the present invention.

Embodiment 2

[0078] Example 2 Astaxanthin extracted with deep eutectic solvent microemulsion of the present invention and residue analysis

[0079] Comprise following operation (same as embodiment 5):

[0080] S1: Preparation of deep eutectic solvent microemulsion extraction system:

[0081] S11. Prepare a deep eutectic solvent: mix proline and ethylene glycol in a molar ratio of 1:3, heat to 80°C until clear and transparent, cool and let it stand at room temperature;

[0082] S12. Preparation of microemulsion extraction system: mix 10%wt of deep eutectic solvent, 52%wt of surfactant, 13%wt of co-surfactant methanol, and 25%wt of cyclohexane, and stir until uniform.

[0083] S2: Add shrimp shell powder to the deep eutectic solvent microemulsion extraction system prepared in S1 at a solid-to-liquid ratio of 1:20 (g / mL), and extract with 70W ultrasound for 60 minutes;

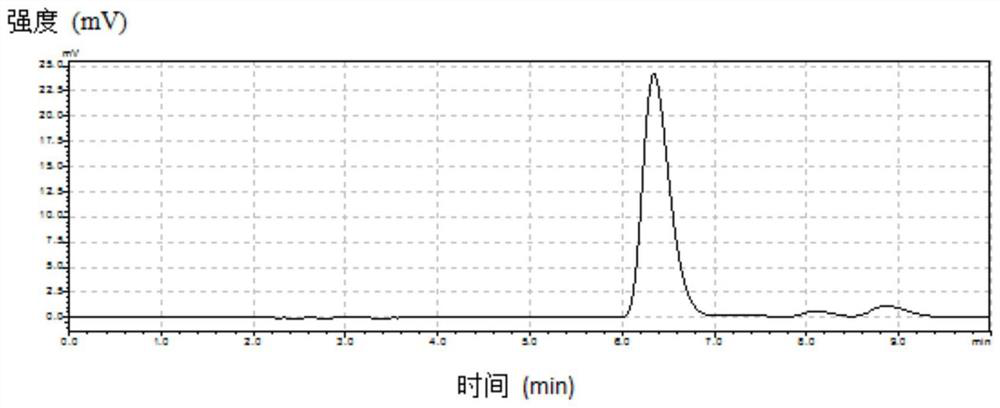

[0084] S3: Centrifuge the reaction solution of S2 at 7000rpm for 8 minutes to separate the solid and liquid, and the supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com