Pillar climbing equipment

A column and equipment technology, applied in the direction of climbing, sports accessories, etc., can solve the problems of high construction cost, low efficiency, environmental pollution, etc., and achieve the effect of improving construction efficiency, improving safety system, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

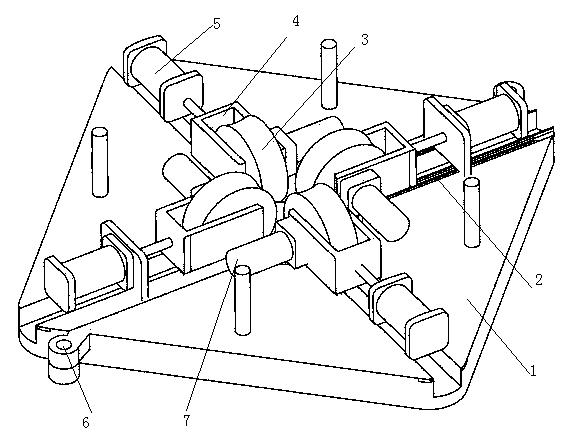

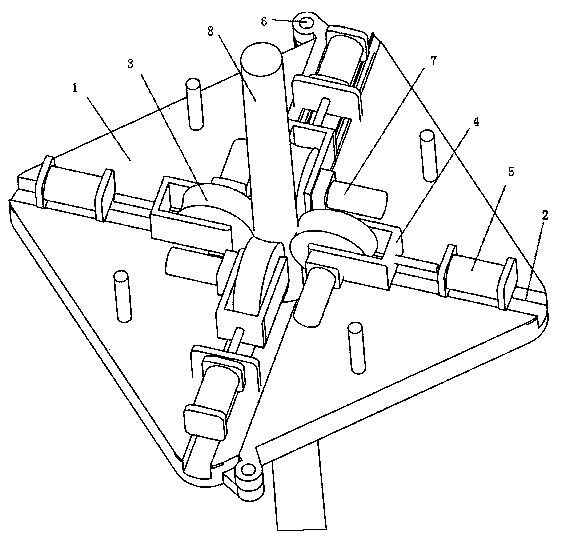

[0022] Such as figure 1 , 2 The column climbing equipment shown is mainly composed of a mobile platform 1. Four slide rails 2 are installed on the mobile platform, and the driving device and the wheel frame 4 are slidably installed on the slide rails. The driving device drives and connects the wheel frame, and the wheel frame is installed Friction wheel 3, the friction wheel is an arc-shaped friction wheel, and the friction wheel is relatively in the shape of a cohesive cylinder. The driving device adopts a reinforced hydraulic cylinder 5, and the driving device is connected with the control device. The mobile platform is an opening and closing structure hinged at one end, and the other end has Locking device 6 is arranged.

Embodiment 2

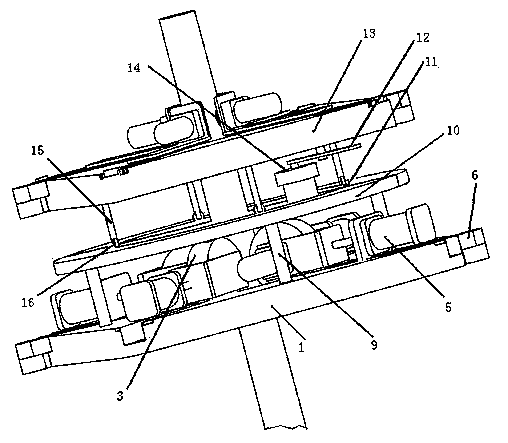

[0024] Such as Figure 3-5 The column climbing equipment shown is mainly composed of a mobile platform 1, an auxiliary platform 10 and a workbench 13. Four slide rails 2 are installed on the mobile platform, and a driving device and a wheel frame 4 are slidably installed on the sliding rails, and the driving device drives Connect the wheel frame, the friction wheel 3 is installed on the wheel frame, the friction wheel is an arc friction wheel, the friction wheel is relatively cohesive cylinder shape, the driving device adopts the enhanced oil pressure cylinder 5, and the driving device is connected with the control device.

[0025] The workbench 13 has 3-5 feet 15 with rollers 16, the rollers are slidably mounted on the circular track 11, the circular track is fixed on the auxiliary platform 10, and the worktable rotation drive motor is installed on the auxiliary platform at the same time 14. A drive rod 12 is installed on the output shaft of the workbench rotation drive motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com