Catalytic system containing phosphate external electron donors for polypropylene polymerization and application of catalytic system

An external electron donor and catalytic system technology, applied in the field of catalytic systems for olefin polymerization, can solve problems such as uncontrollable temperature adjustment, parking, and increased heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

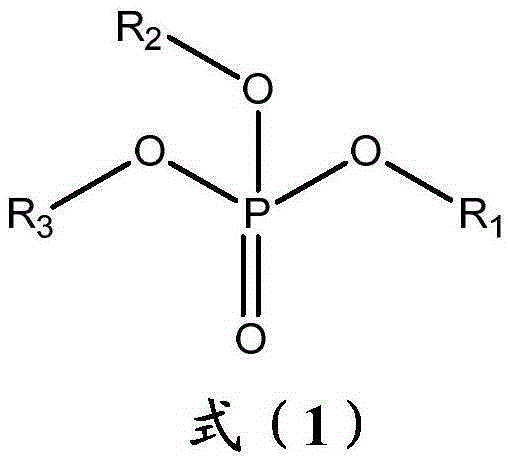

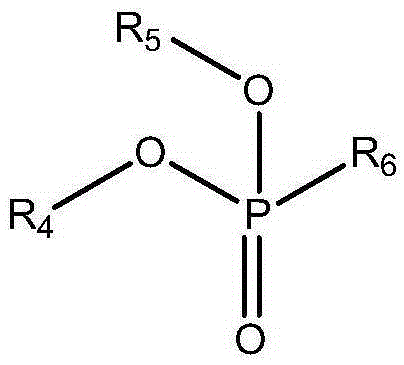

Method used

Image

Examples

Embodiment 1

[0092] Heat the 5L high-pressure reactor to vacuumize, remove air and water, replace with nitrogen, repeat three times, and then add MgCl 2 Loaded TiCl 4 Catalyst solid component 20mg (internal electron donor is diisobutyl phthalate), the content of Ti in the solid component is 2.36wt%, the addition of triethylaluminum is Al / Ti (mol)=600, bicyclic Amyldimethoxysilane, triisopropyl phosphate, the molar ratio of the two is 30:70, the molar ratio of the two external electron donors to Ti is 30, and then 168mmol hydrogen and 1.2 kg propylene. Close the reaction kettle, raise the temperature of the kettle to 70° C., and start polymerization. After 1 hour of reaction, unreacted propylene is discharged to obtain 720 g of polypropylene particles, the catalytic activity is 36.6KgPP / g catalyst, and the isotacticity is 99.5% (see Table 1 ).

Embodiment 2-12

[0094] The polymerization process was the same as in Example 1, only the type and ratio of the external electron donor were changed. The results are shown in Table 1.

[0095] The result of table 1 embodiment 1-12

[0096]

[0097] D1: the first type of electron donor, D2: the second type of electron donor.

[0098] D: Dicyclopentyldimethoxysilane, C: Methylcyclohexyldimethoxysilane, B: Diisobutyldimethoxysilane, P: Diisopropyldimethoxysilane, NPTMS: Normal Propyltrimethoxysilane, DPTMS: Cyclopentyltrimethoxysilane.

Embodiment 13

[0100] Others are the same as in Example 1, except that the polymerization temperature is 90°C, the catalytic activity is 24.3KgPP / g catalyst, and the isotacticity of polypropylene is 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com