Olefin polymerization catalyst, as well as combined catalyst containing same and application thereof

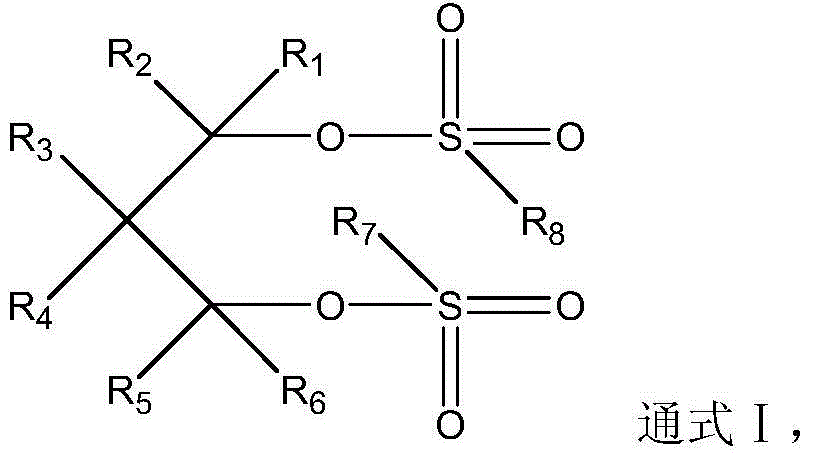

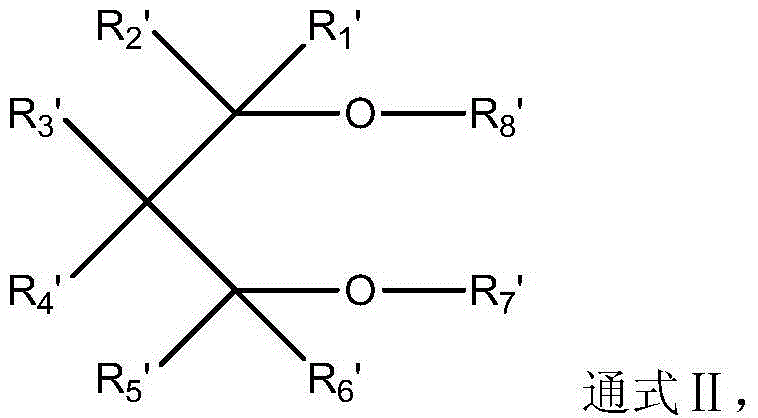

A technology for olefin polymerization and catalysts, which is applied to olefin polymerization catalysts and combined catalysts containing it and its application fields, and can solve problems such as inconvenience, narrow molecular weight distribution of propylene homopolymer, and inconvenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] This embodiment provides an olefin polymerization catalyst, which is prepared by the following method:

[0090] Spherical MgCl 2 / SiO 2 The preparation of the composite carrier is carried out in two steps:

[0091] 1) preparation of spray-dried mother liquor: after passing through N 2 Add 200mL of dehydrated ethanol to the fully replaced 400mL reactor with stirring; at room temperature, add 20g of anhydrous magnesium chloride while stirring, and control the adding speed of magnesium chloride to keep the system temperature below 40°C; the addition of magnesium chloride is complete Finally, the temperature of the mixed system was raised to 70°C, and kept at this temperature for 4 hours to obtain a uniform ethanol solution of magnesium chloride; Mother liquor;

[0092] 2) Preparation of MgCl by spray drying 2 / SiO 2 Spherical carrier: use a spray dryer to prepare a composite carrier; use a peristaltic pump to introduce the obtained mother liquor into a two-fluid nozz...

Embodiment 2

[0096] This example provides an olefin polymerization catalyst, the preparation method of which is basically the same as that in Example 1, the only difference is that in addition to adding 1,8-binaphthol di-p-toluenesulfonate, at the same time adding o-benzene Dibutyl diformate, its use amount is 1.24g.

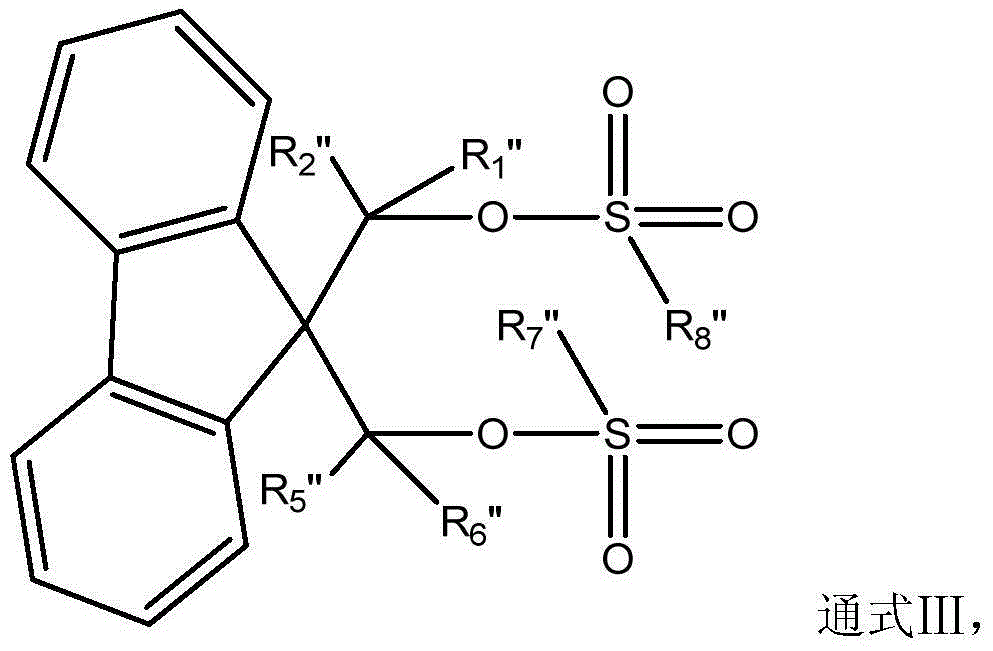

Embodiment 3

[0098] This example provides an olefin polymerization catalyst whose preparation method is basically the same as that in Example 1, the only difference being that 1,8-binaphthol di-p-toluenesulfonate is replaced by 9,9-bis (P-toluenesulfonate methyl) fluorene, the usage amount is 3.20 g, and 9,9-bis(methoxymethyl) fluorene is added at the same time, the usage amount is 1.16 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com