Polypropylene composition with low gloss, scratch resistance and high impact resistance and preparation method of polypropylene composition

A high-impact polypropylene and scratch-resistant technology, which is applied to the high-impact polypropylene composition and its preparation, scratch-resistant, low-gloss fields, and can solve the problems of low erucamide addition, sticky surface, and Solve problems such as strong erucic acid smell, achieve uniform dispersion, improve scratch resistance, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiment:

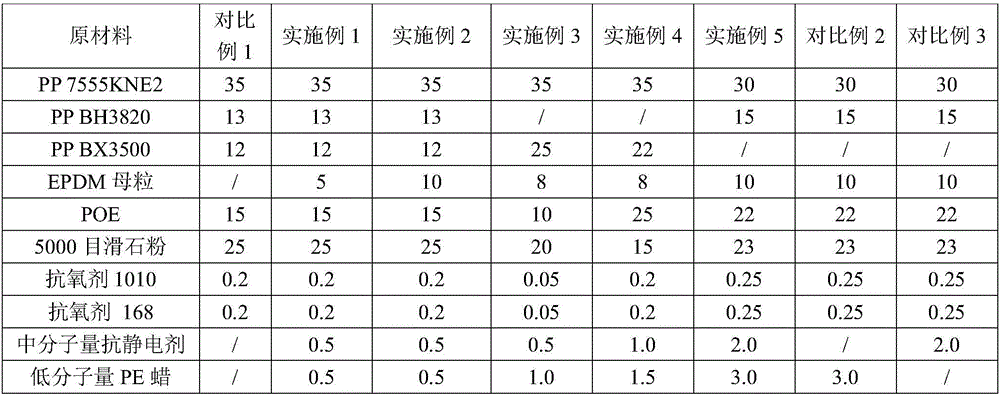

[0024] A kind of low gloss, anti-scratch, high-impact PP composition, the formulation composition (parts by weight) of embodiment 1-5 and comparative example 1-3 is as follows table 1:

[0025] Table 1 Low gloss, scratch resistance, high impact PP composition embodiment 1-5 and the formula composition of comparative example 1-3

[0026]

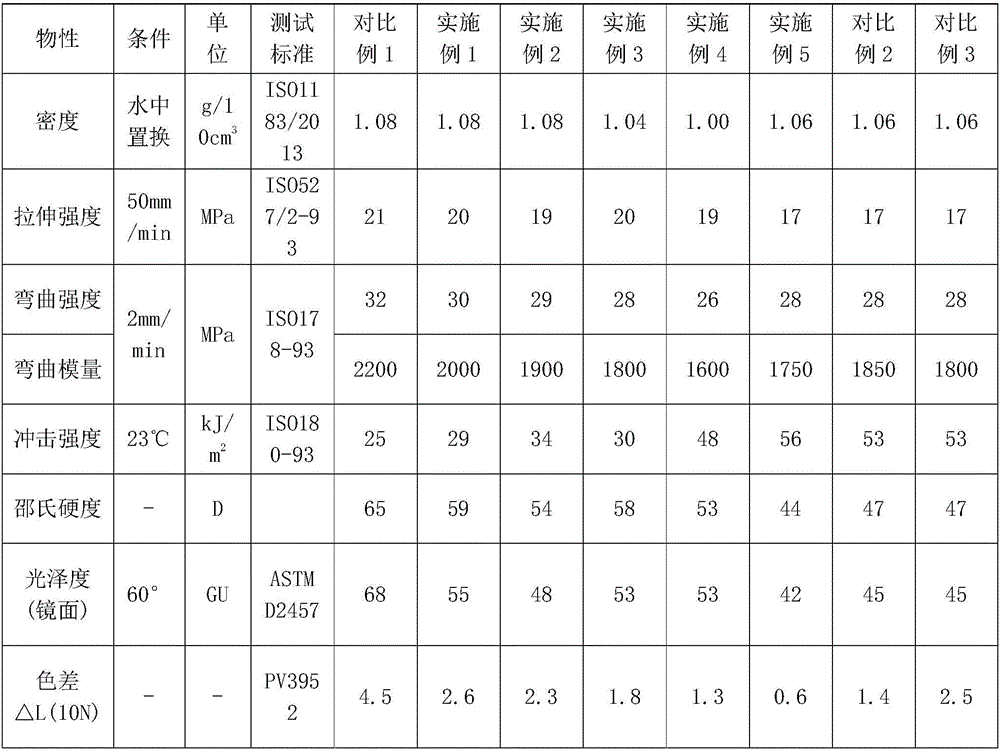

[0027] The performance of the composite material prepared by Examples 1-5 and Comparative Examples 1-3 is as follows in Table 2:

[0028] The performance of the composite material prepared by the present invention of table 2

[0029]

[0030] summary:

[0031] 1) Test its specular gloss according to ASTM D2457 60 °, comparative example 1 formula, gloss is 68GU; Embodiment 1 adds 5% EPDM master batch, and gloss is 55GU; Embodiment 2 adds 10% EPDM master batch, gloss Be 48GU; Therefore add the EPDM masterbatch that the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com