Buttonholing machine

A keyhole machine and machine body technology, applied in the field of sewing machines, can solve the problems of increased friction, transmission energy consumption, complex transmission structure, and increased production costs, and achieve the effects of reducing friction, solving complex structures, and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

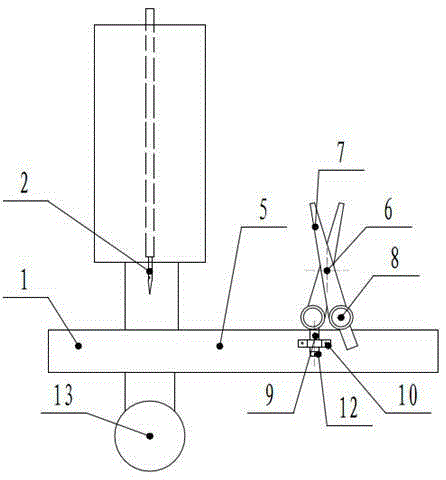

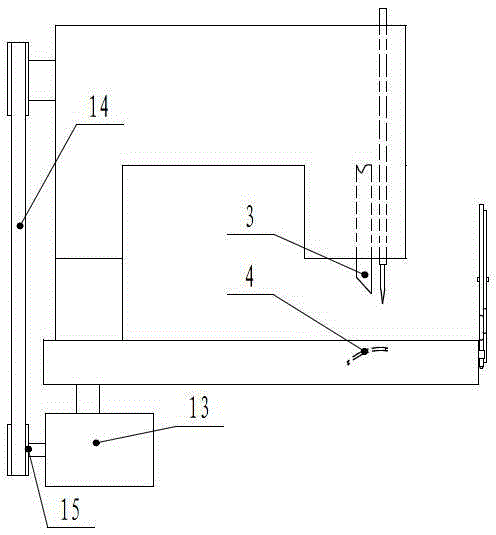

[0014] Such as Figure 1~3 As shown, a buttonhole machine includes a body 1, the body 1 has a machine needle 2 driven by a transmission mechanism driven by a two-phase motor 13, a hole knife 3 and a hook needle 4, and is fixedly installed on a machine platform 5, so that A detachable thread cutter 6 is placed on the front side of the machine table 5 .

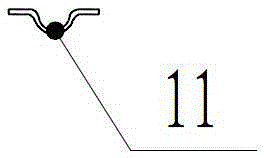

[0015] Preferably, the above-mentioned thread cutter 6 includes mutually intersecting rotatable blades 7 and a ring handle 8, the ring handle 8 is provided with a pole 9, and the pole 9 faces the other side connected to the blade 7, and is connected with the The blade 7 remains on the same plane, and the middle finger or the ring finger are conveniently lapped on it when the thread is cut through the pole, which is labor-saving and easy to operate.

[0016] Preferably, the above-mentioned support rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com