Floor drain

A technology for floor drains and housings, applied in waterway systems, buildings, water supply devices, etc., can solve the problems of floor drains losing their seal and deodorization, and achieve the effect of preventing water return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

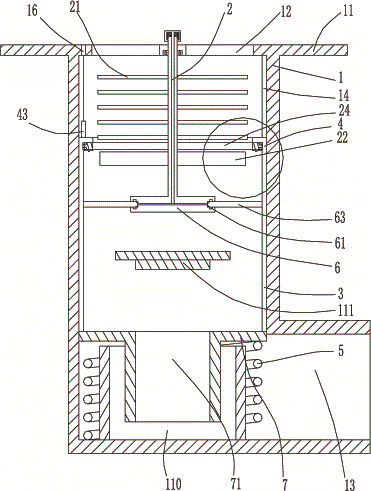

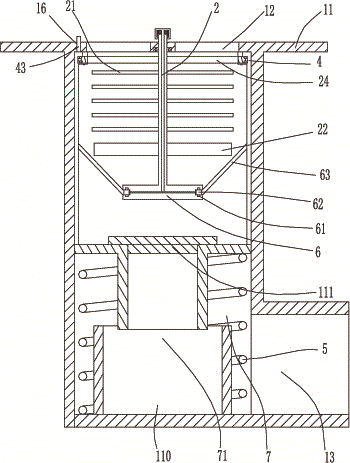

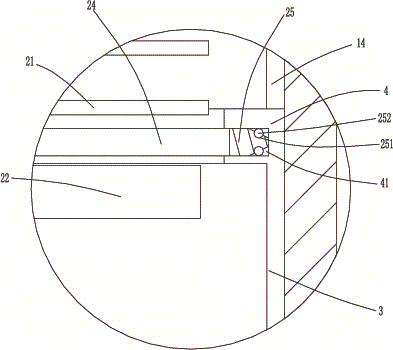

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 7 , a floor drain, comprising a cylindrical housing 1, a flange 11 is provided on the top edge of the housing 1, a number of first through holes 12 are provided on the top of the housing 1, and a water outlet is provided on the side of the housing 1 13. The top of the housing 1 is rotated with a first rotating shaft 2, the first rotating shaft 2 is provided with an impeller 22, and the inner side of the housing 1 is vertically provided with several second chute 14, and several of the second A slide bar 3 is slidingly arranged in the chute 14, and a plurality of slide bars 3 upper ends are jointly connected with a slide ring 4, and the bottom of the first rotating shaft 2 is provided with a reel 6, and the reel 6 is provided with a ring The third chute 61, the third chute 61 is provided with a number of sliders 62, a nu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap