Pressure sensor temperature measuring system

A technology for sensing temperature and pressure, applied in the field of measurement, can solve the problems of induction lag, temperature drift correction accuracy affecting pressure, and measurement asynchrony, etc., to achieve the effect of increasing temperature measurement capability, ensuring synchronization, and rapid temperature sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

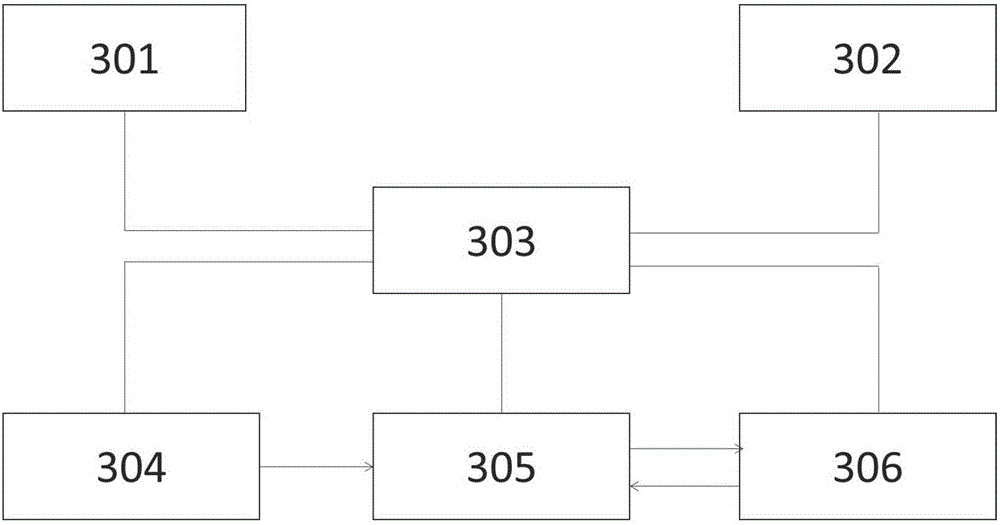

[0045] A pressure sensing and temperature measuring system is realized by using a pressure sensor and a single-chip microcomputer, such as image 3 As shown, it includes a control module 303 and a communication module 302 connected thereto, a data acquisition module 304, a data storage module 305 and a digital filtering module 306;

[0046] The control module 303 sends control instructions to the communication module 302, the data acquisition module 304, the data storage module 305 and the digital filtering module 305;

[0047] The communication module 302 is used for communicating with the upper computer;

[0048] The data collection module 304 adopts the same sensor to simultaneously collect pressure signals and temperature signals, and the signals are saved to the data storage module 305;

[0049] The data storage module 305 is used to complete the control and read and write of the underlying FLASH memory chip;

[0050] The digital filtering module 306 extracts stored dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com