Shield segment lining connector structure with limiting function

A shield segment and segment technology, which is applied in the field of prefabricated segment lining of shield tunnels, can solve the problems of weakened segment structure, high requirements for segment formwork, and difficulty in segment assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

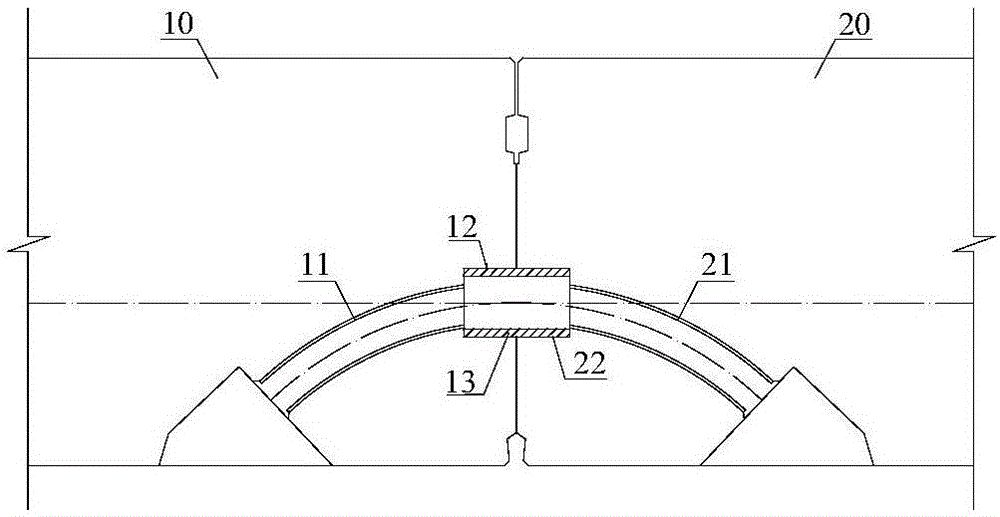

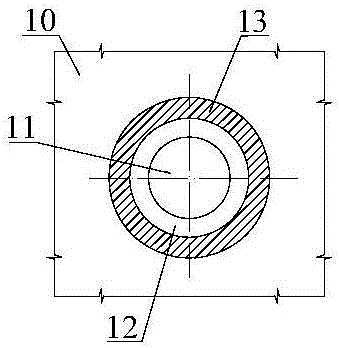

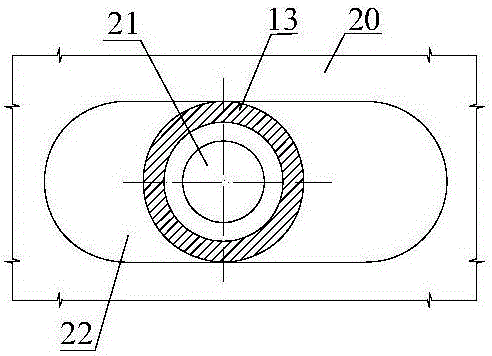

[0018] refer to figure 1 , figure 2 with image 3 , a shield segment lining joint structure with a position-limiting function in the present invention, comprising a pre-sequence assembled segment 10 with a bolt front tunnel 11 and a post-sequence assembled segment 20 with a bolt rear tunnel 21, the connecting bolts pass through The corresponding bolt front channel 11 and bolt rear channel 21 assemble and connect the pre-order assembled segment 10 and the subsequent assembled segment 20 into one. A limit mortise 12 is set on the port of the bolt front channel 11 at the splicing seam on the pre-sequence assembled segment 10, and a limit tenon 13 with a through hole for the connecting bolt to pass through is installed at the rear of the limit mortise. Mortise 12 inside. The post-sequence assembled segment 20 is provided with a limit tenon groove 22 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com