Positionable overrunning clutch

An overrunning clutch and separation technology, applied in the field of machinery, can solve the problems of increased volume and price, uncertain driven position, etc., and achieve the effect of reducing processing cost and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

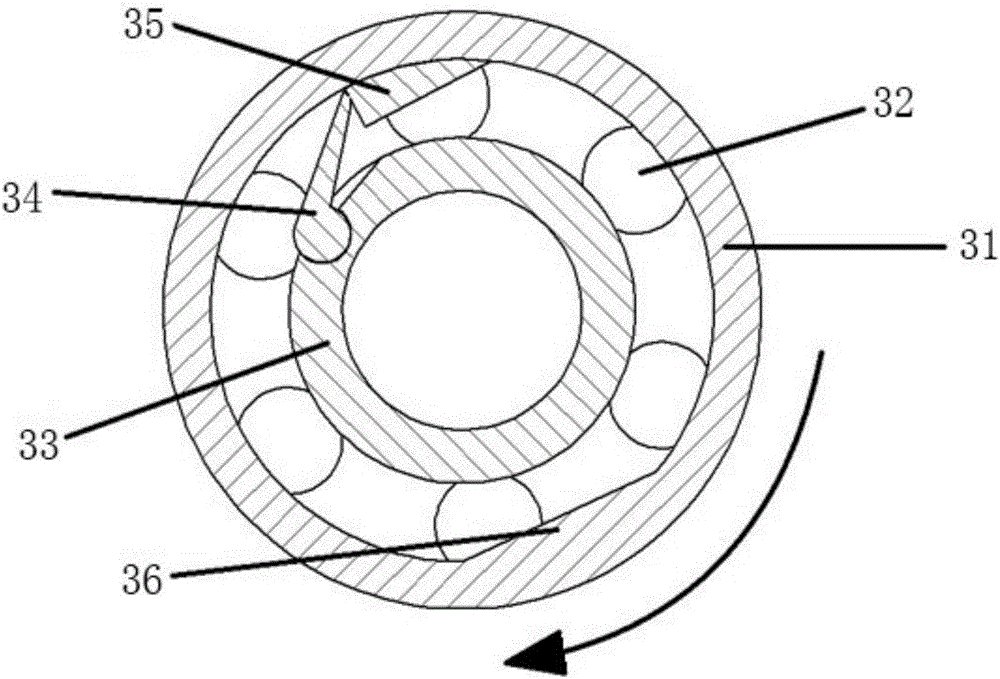

[0045] This embodiment provides a positionable overrunning clutch, which is a typical one-piece type with a structure such as Figure 3A , Figure 3B As shown, it includes an inner ring 33 , an outer ring 31 , a ball 32 , a pawl 34 , a ratchet 35 , a raised weight 36 and a spring 37 . The outer wall of the inner ring 33 contains an inner ring channel 39 along the circumference, and the same height on the inner wall of the outer ring 31 contains a corresponding outer ring channel 38 along the circumference. The balls 32 in the groove are movably connected together. A unique pawl 34 and a unique ratchet 35 are respectively provided on the inner ring 33 and the outer ring 31 .

[0046] The ratchet 34 comprises a pawl tip and a pawl root that is rotatably connected to the inner ring. The position of the pawl root on the inner ring 33 is a cylindrical groove with one side opening, and the opening width is less than the diameter of the cylindrical groove. A cylinder that fits the...

Embodiment 2

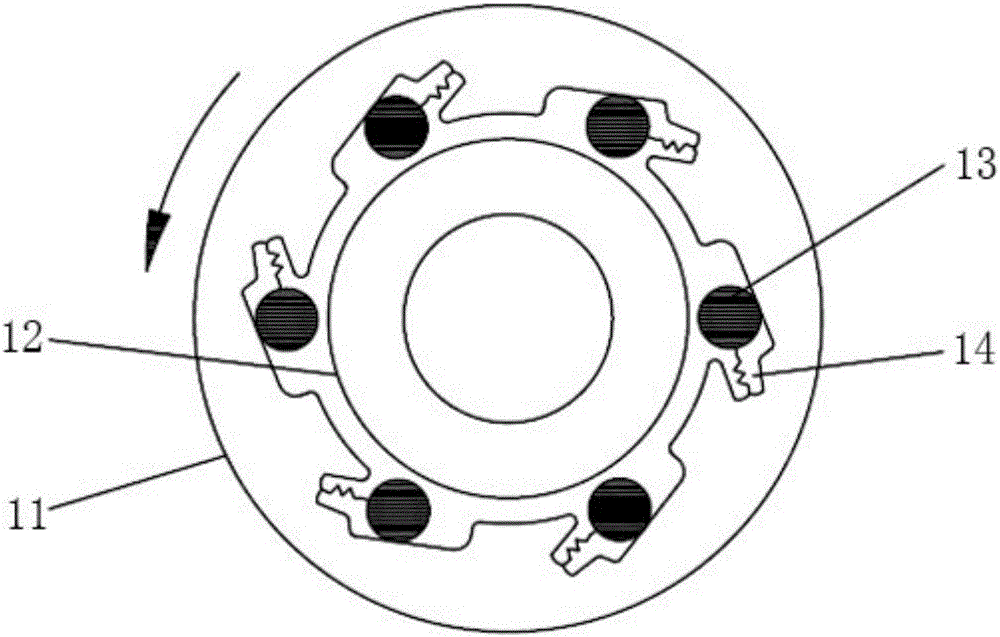

[0048]The above embodiment has an integrated structure, but in order to adapt to more installation environments, the clutch can also be a separate structure, which has three types, including the inner ring separated type, the outer ring separated type and the inner ring and outer ring separated type. This embodiment provides a positionable overrunning clutch with a separate inner ring, such as Figure 4 As shown, the structure is generally the same as that of Embodiment 1, the difference is that the inner ring is divided into two parts: the positioning inner ring 42 and the sliding inner ring 44, the pawl and the spring are located on the positioning inner ring 42, and the groove is located on the sliding inner ring 44 superior.

Embodiment 3

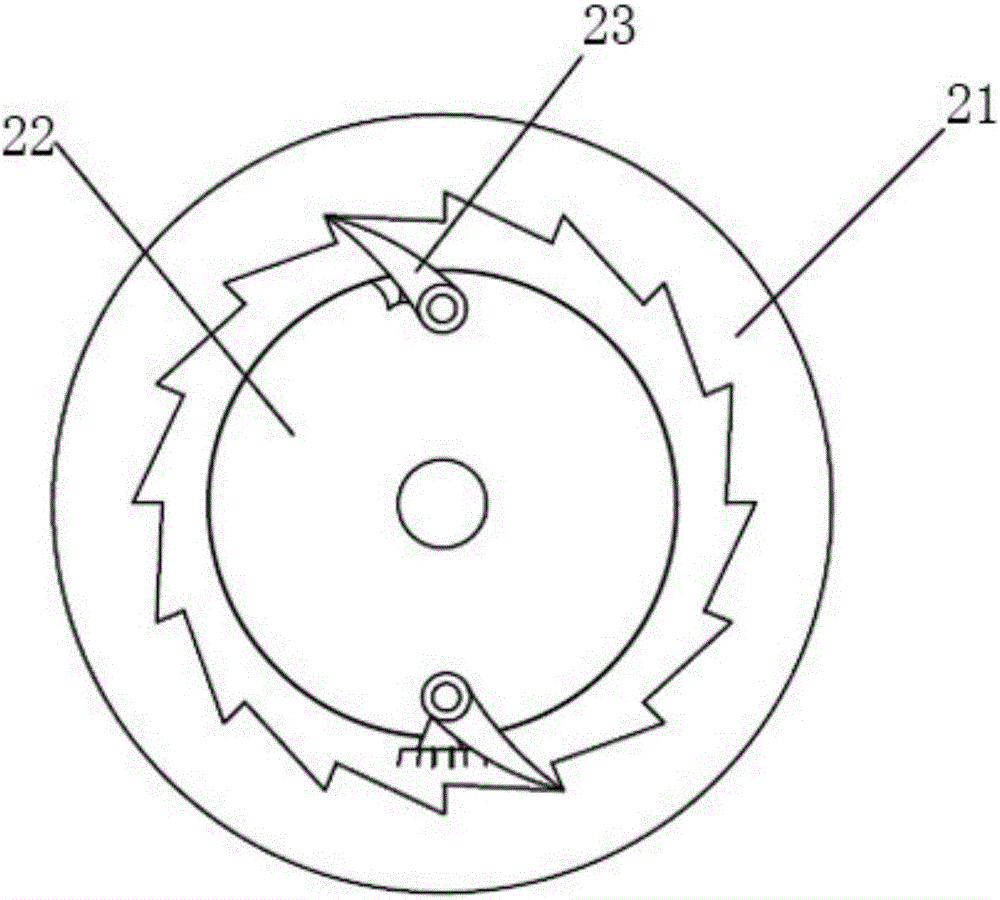

[0050] This embodiment provides a positionable overrunning clutch of the outer ring separation type, such as Figure 5 As shown, the structure is generally the same as that of Embodiment 1, the difference is that the outer ring is divided into two parts: the positioning outer ring 52 and the sliding outer ring 51, the ratchet and the protruding weight are located on the positioning outer ring 52, and the grooves are located on the sliding outer ring 52. 51 on the outer ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com