A method to reduce the engine noise by the right time of the engine of the engine

A timing gear and engine technology, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem of limited improvement of gear accuracy, reduce friction, improve transmission smoothness, and reduce noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

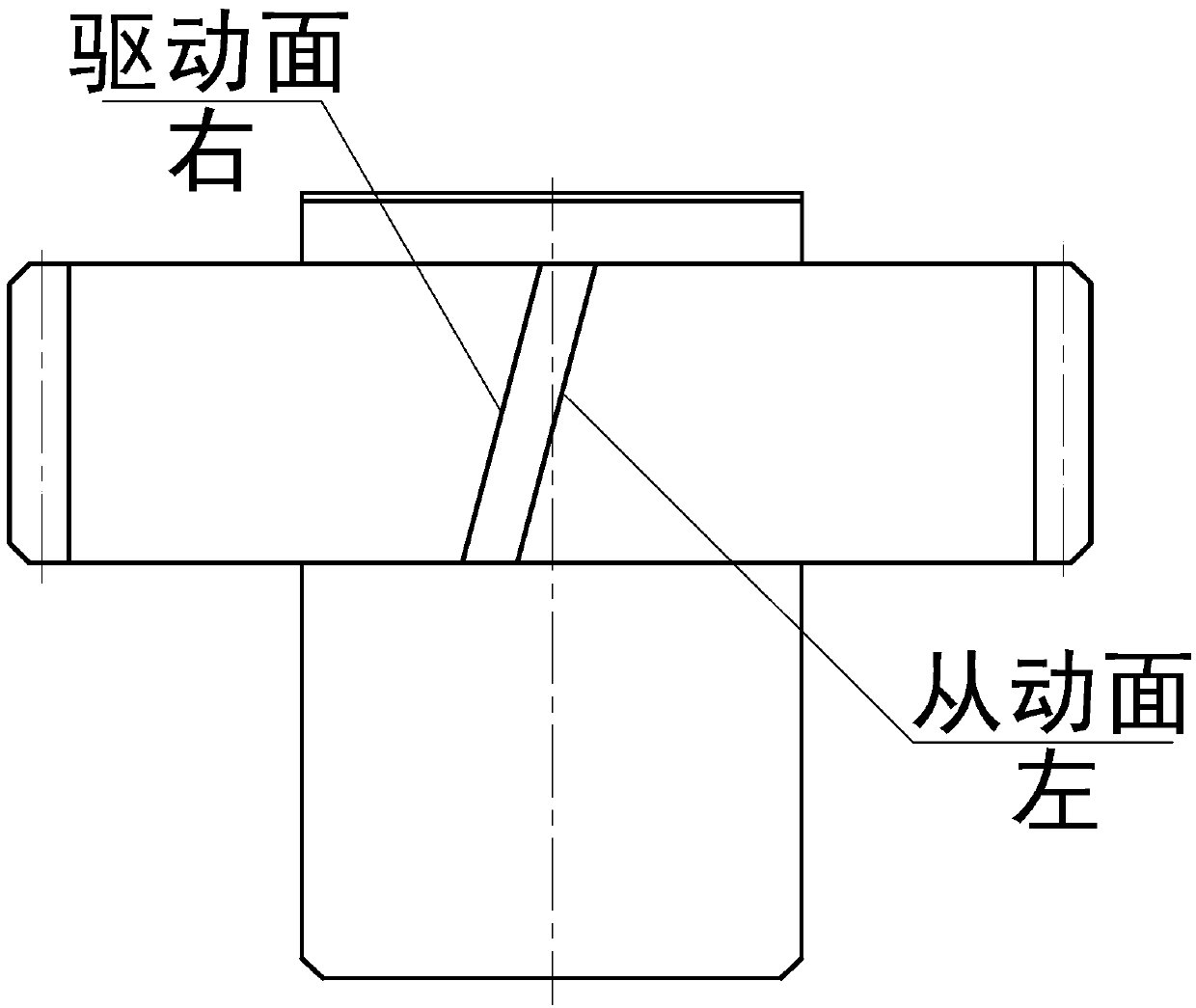

[0025] The modified gear in this example is as Figure 8 As shown, the gear parameters are as follows: modulus m=1.75, number of teeth z=31, pressure angle α=17.5°, helix angle β=31° (right-handed). Figure 9 Local zoom in as Figure 10 as shown, Figure 10 Among them, Fβ is the tooth direction along the tooth width trajectory, and Fα is the tooth root to tooth top trajectory.

[0026] The specific implementation method is as follows:

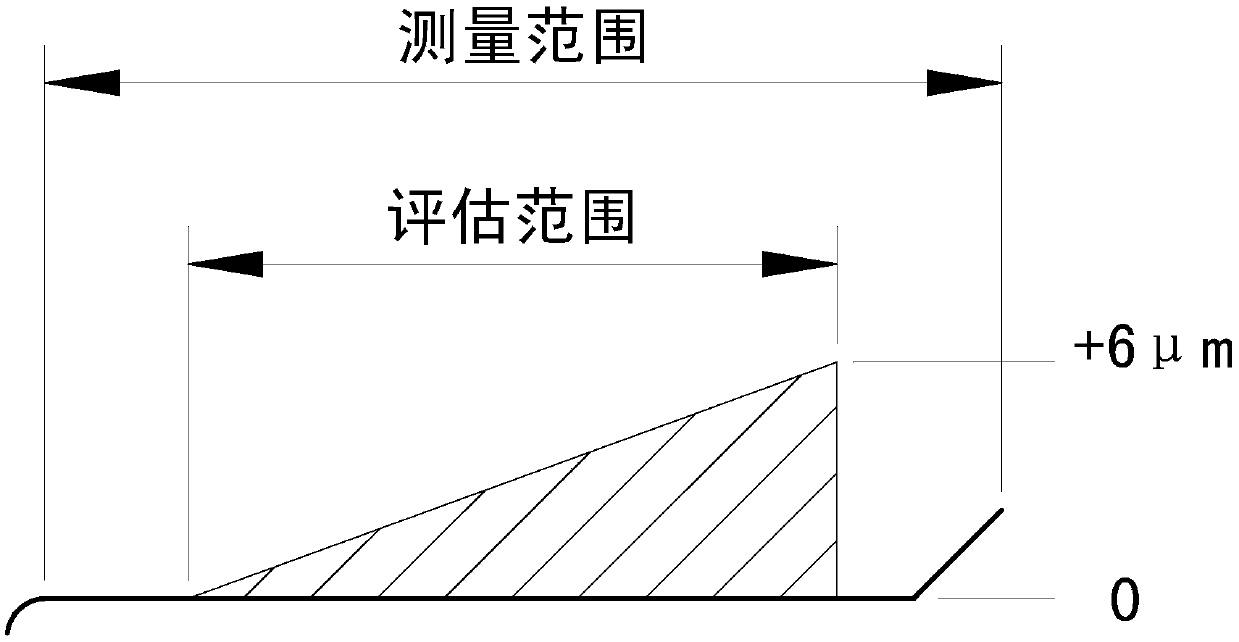

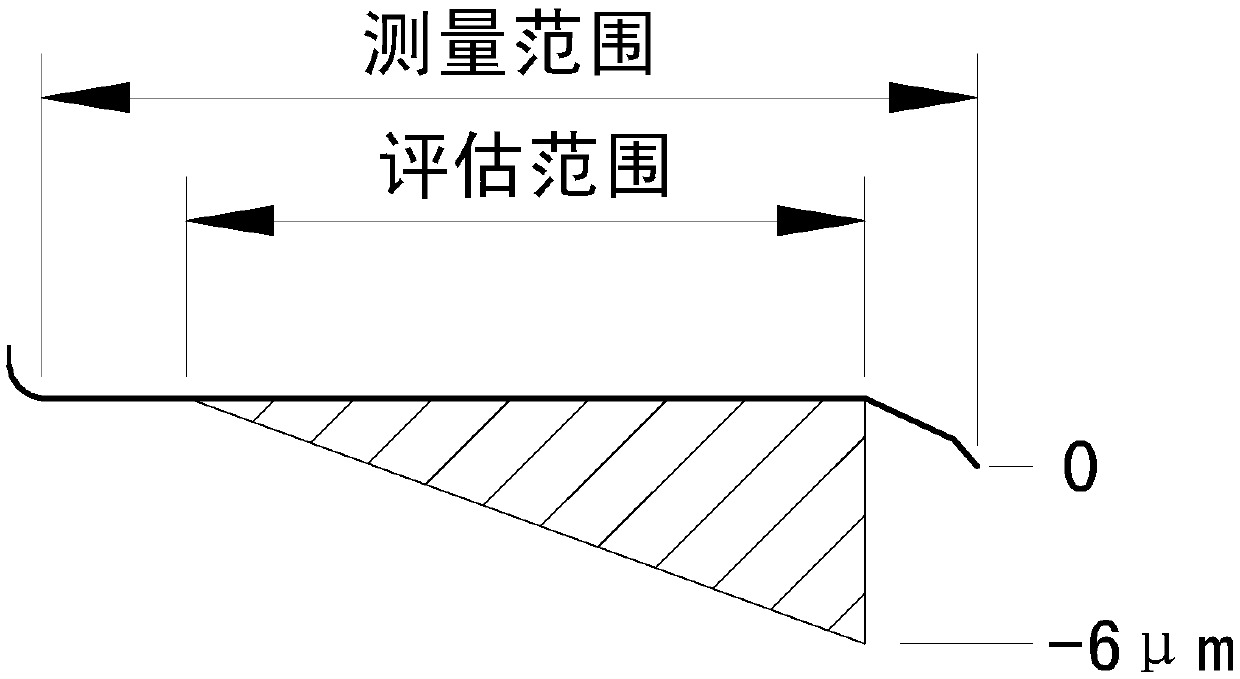

[0027] According to the technical solution of the present invention, the tooth direction Fβ is modified, and the tooth direction sectional view is as follows Figure 9 As shown, the helix angle deviation FHβ within the tooth width range of 32mm is controlled to be ±3μm, the drum shape Cβ is controlled to be 4-9μm, and the edge trimming amount is 3-8μm in the range of 4mm at both ends of the tooth width.

[0028] According to the technical scheme of the present invention, the tooth shape Fα is modified, and the tooth shape cross section is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com