Speed reducer shell

A technology of reducer and casing, which is applied in the field of reducer casing and casing, which can solve the problems of affecting the service life of the reducer, difficulty in ensuring the sealing effect, and leakage of lubricating oil, so as to achieve broad application prospects and promotion value, and improve the effect of oil leakage prevention , the effect of solving the oil leakage phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

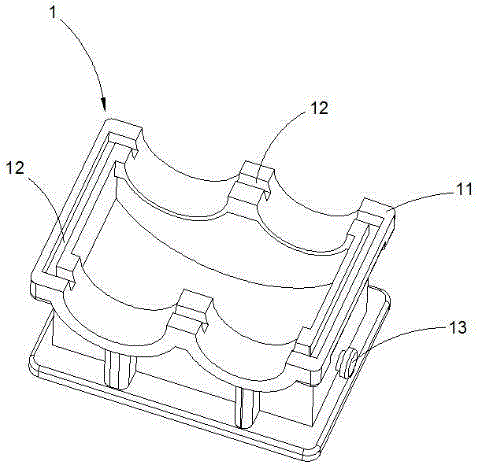

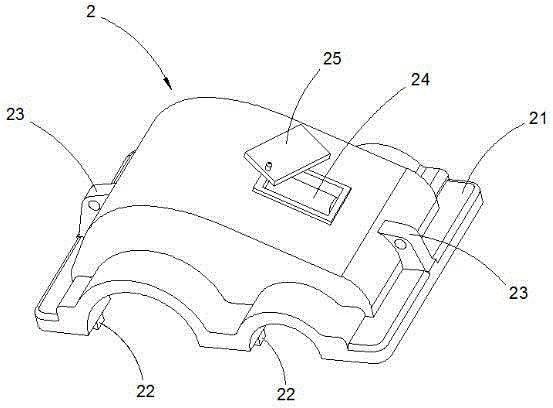

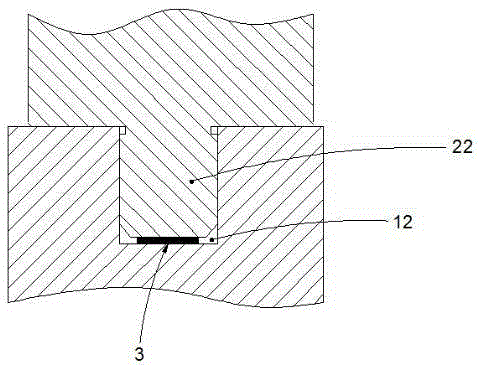

[0020] Figure 1 to Figure 3 , is a schematic diagram of a preferred embodiment of a reducer housing provided by the present invention. Such as Figure 1 to Figure 3 As shown, the material of the reducer shell is cast iron HT200 with good processing performance and excellent shock absorption performance, which specifically includes a box body 1 and a cover body 2. The bottom cover of the cover body 2 is buckled on the top of the box body 1, and the box body 1 A circle of first flanges 11 is provided on the top, a circle of second flanges 21 is provided at the corresponding matching position on the bottom of the cover body 2, a circle of grooves 12 is formed on the first flange 11, and a circle of grooves 12 is formed on the second flange 21. The boss 22 whose shape matches the groove 12, in order to facilitate processing and manufa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com