Improved Furnace Core for Compression Combustion Furnace

A combustion furnace, an improved technology, applied in burners, combustion equipment, combustion using liquid fuels and gaseous fuels, etc. Stable, easy to clean, smooth air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

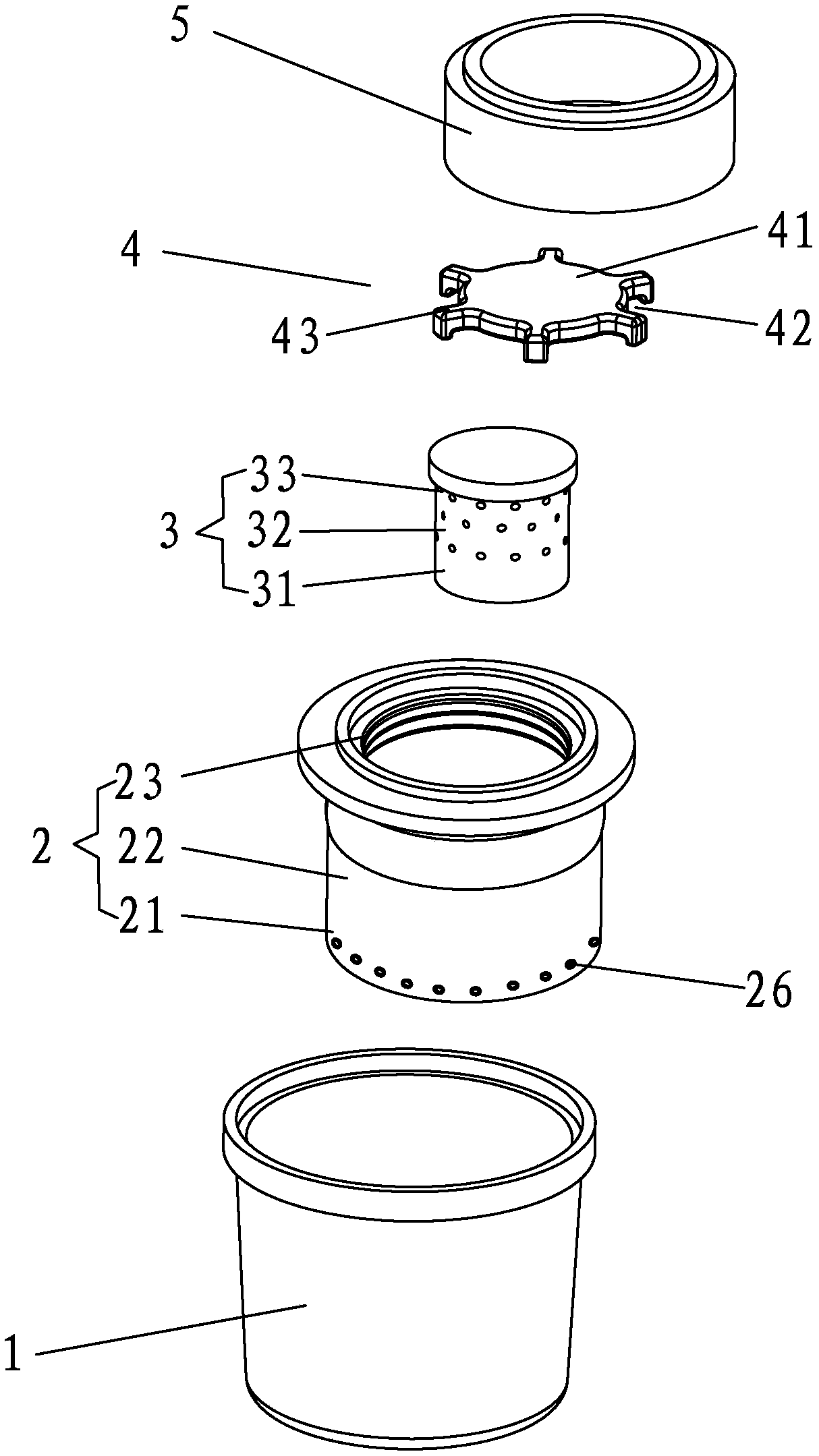

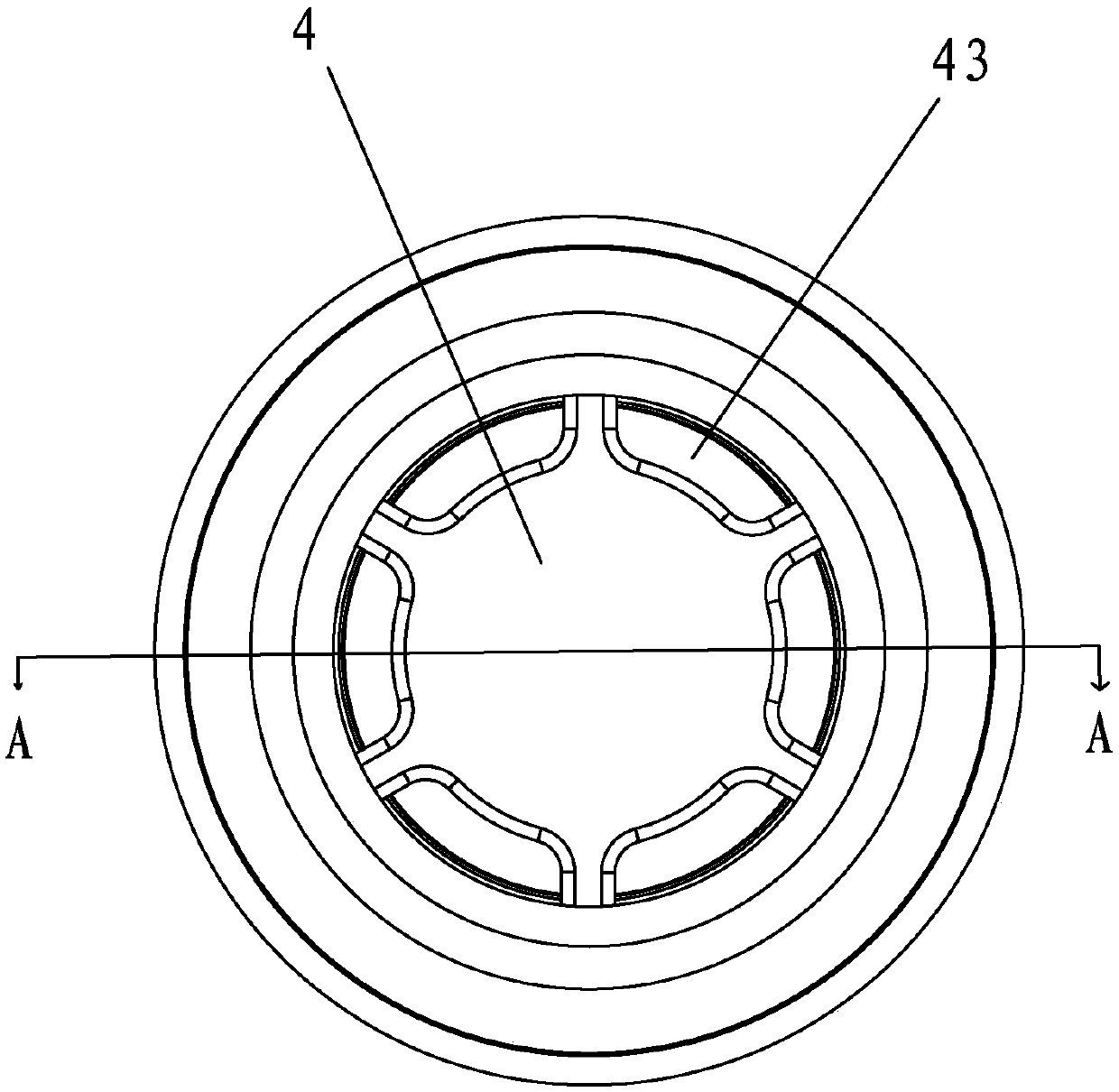

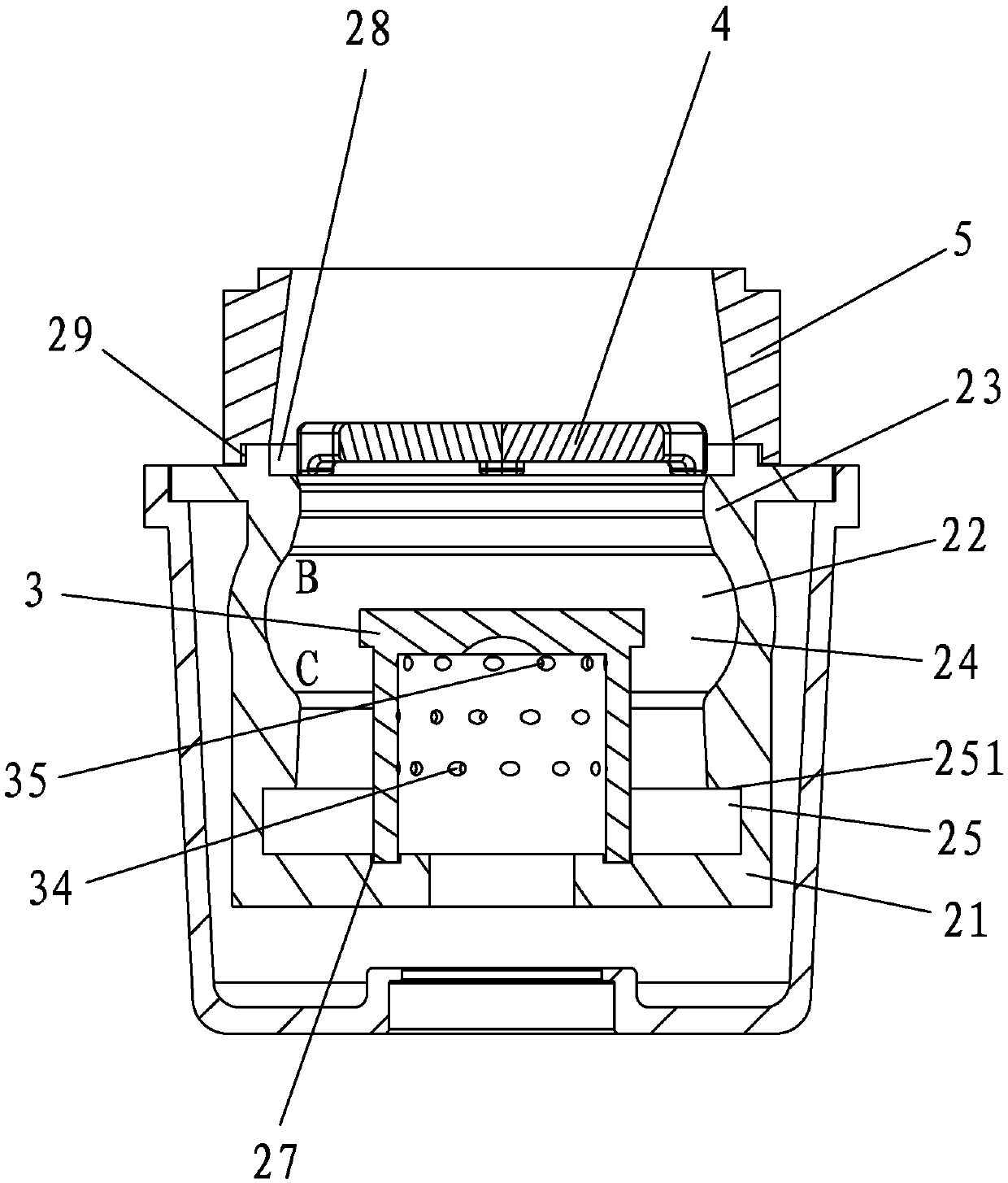

[0037] An improved core for a compression combustion furnace having a core body such as Figure 1-3 As shown, the main body of the furnace core includes an outer casing 1 , a main casing 2 , a wind control cylinder 3 , a gasification cover 4 and a fire stabilization ring 5 . The outer casing 1 is sleeved outside the main casing 2, the wind control cylinder 3 is installed in the main casing 2, the gasification cover 4 is sealed at the opening of the main casing 2, and the fire stabilization ring 5 is installed in the main casing On the open end of the body 2, the adjustment makes the flame burned out by the combustion furnace more stable and concentrated, and the energy utilization rate is improved.

[0038] by image 3 The orientation shown is a reference orientation, and the inside of the main housing 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com