Electric heating heat storage incineration waste gas treatment device

An exhaust gas treatment device, electric heating technology, applied in heat storage equipment, lighting and heating equipment, incinerators, etc., can solve the problems of lack of monitoring of temperature and pressure operating conditions, fire and explosion hazards, flame extinguishing, etc., to achieve Improve safety hazards, save power consumption, and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

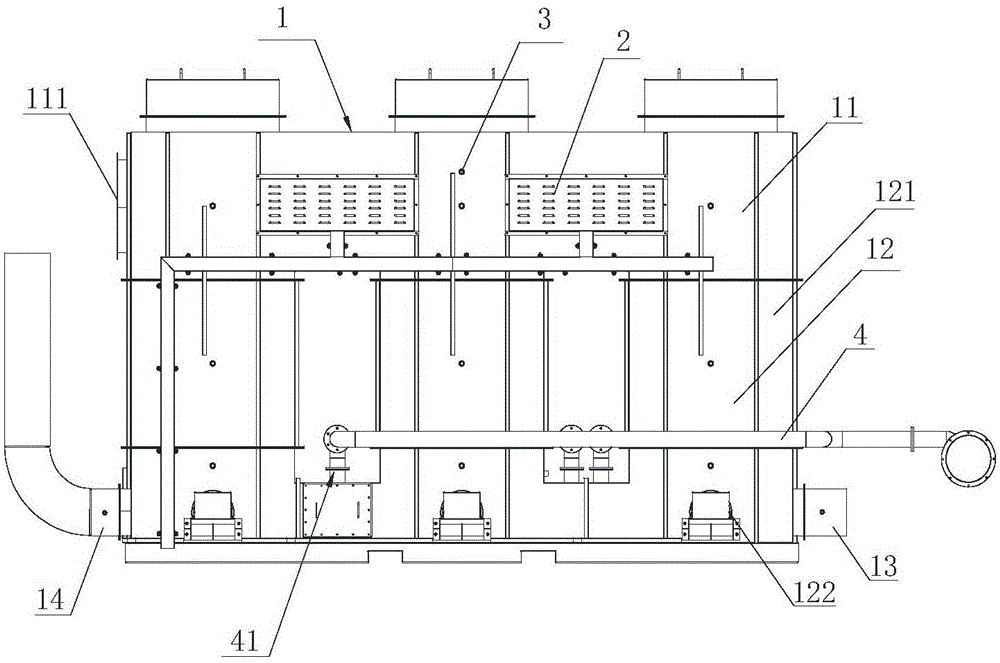

[0019] According to the attached figure 1 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0020] see figure 1 , an electric heating type thermal storage incineration exhaust gas treatment device according to an embodiment of the present invention, comprising a furnace body 1, a PLC control mechanism, a remote monitoring mechanism (not shown in the figure), at least one electric heating rod 2, at least one temperature Sensor 3 , multiple regenerative heat exchangers, a heat regulating device, a gas distribution chamber (not shown in the figure) and a back-purging pipeline 4 .

[0021] Wherein, the body of furnace 1 includes an oxidation chamber 11, a plurality of heat storage chambers 12, an air inlet 13 and an air outlet 14, and an electric heating rod 2 and a temperature sensor 3 are fixed in the oxidation chamber 11, and the electric heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com