Humidifying and cooling device for textile workshop

A cooling device and workshop technology, applied in the textile field, can solve the problems affecting the normal operation of the equipment and have a large impact, and achieve the effects of remarkable humidification effect, sensitive control and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

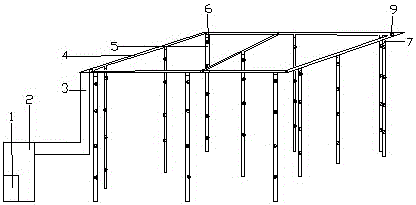

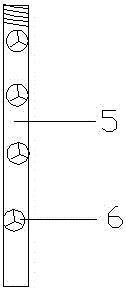

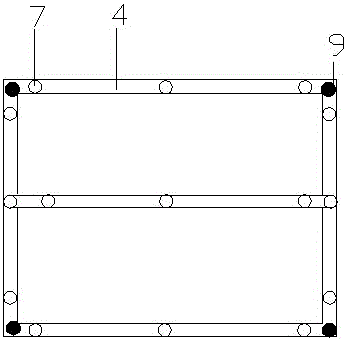

[0015] Specific embodiments: as shown in Figures 1, 2, 3, and 4, a humidification and cooling device for a textile workshop includes a refrigeration compressor 1 installed at the water storage place of a humidifier 2, and the humidifier 2 communicates with the humidifier 2 through a communication pipe 3. The humidification conduit 4 is connected. The humidification conduit 4 is horizontally installed on the top of the workshop, and the lower side is evenly provided with a threaded interface 7. The humidification branch pipe 5 is vertically installed on the lower side of the humidification conduit 4 through the threaded interface 7. The atomization The spray head 6 is evenly installed on the humidification branch pipe 5 , and the humidity sensor 9 is installed at the joint of the humidification conduit 4 and is electrically connected with the humidifier 2 . It can cool down and humidify in a high temperature environment.

[0016] Preferably, the lower side of the humidification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com