Adaptive Robust Force Control Method for Simplified Periodic Disturbance Compensation

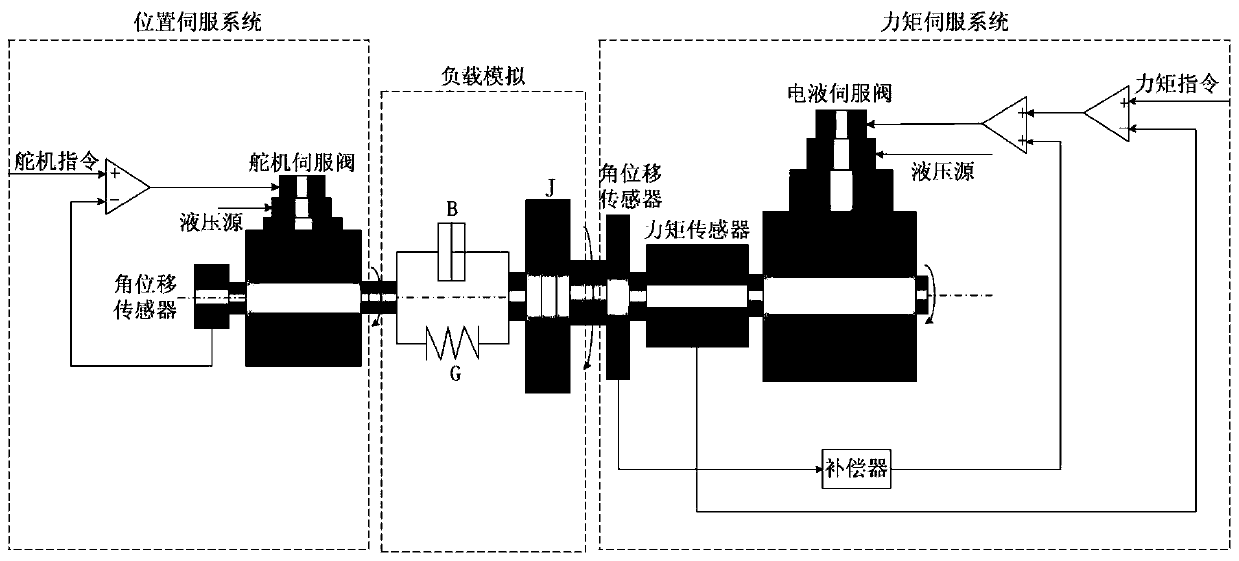

A technology of disturbance compensation and control method, applied in the direction of adaptive control, general control system, control/regulation system, etc., which can solve problems such as model uncertainty, controller discontinuity, and high-gain feedback parameter estimation accuracy, and achieve Effects of improving accuracy and improving tracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

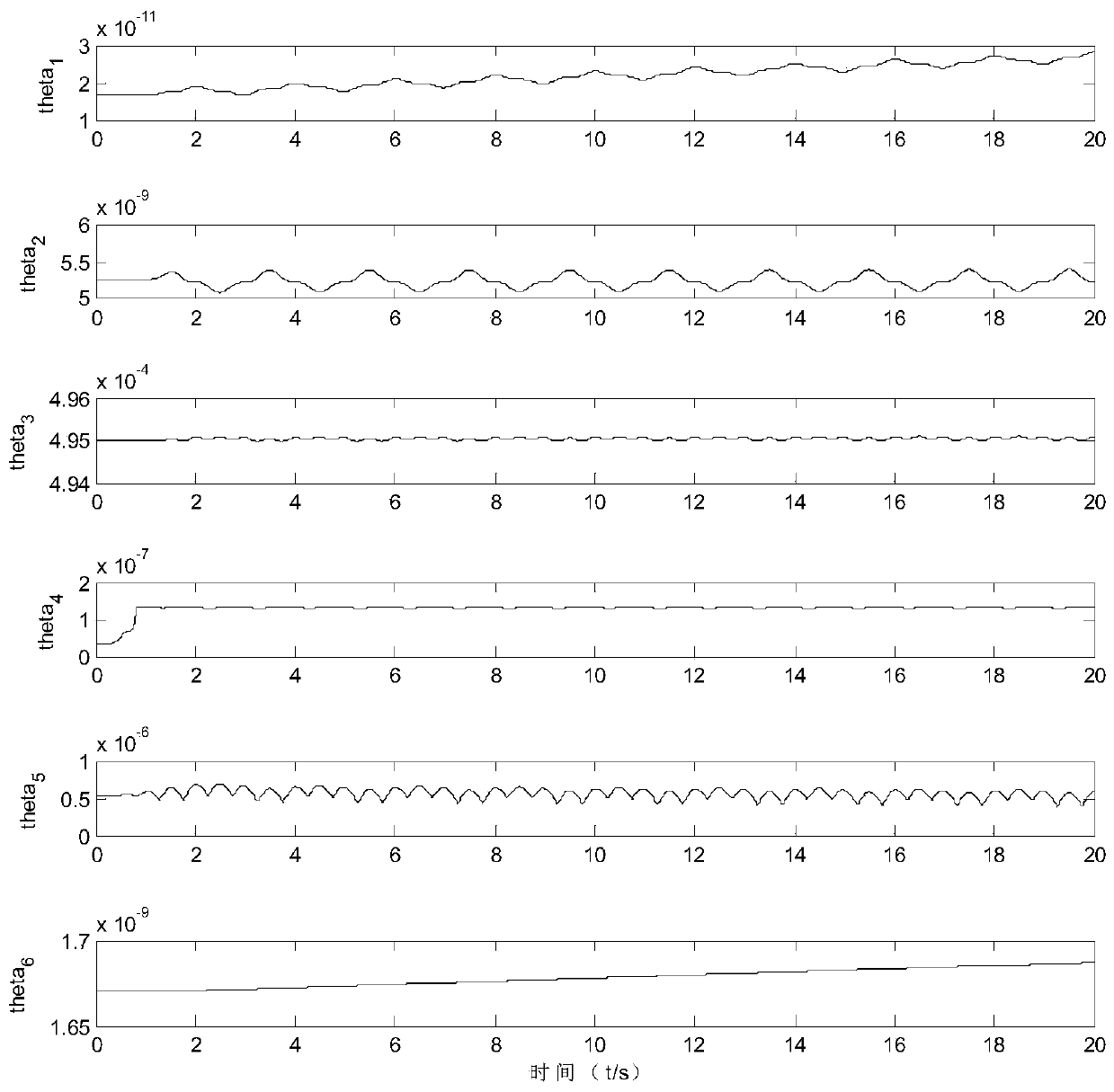

[0105] The parameters of the dual-vane hydraulic motor force control load simulator are: A=9×10 -4 m 3 / rad, B=4000N m s / rad, β e =7×10 8 Pa, C t =9×10 -12 m 5 / (N·s), P s =10×10 6 Pa, P r = 0 Pa, V t =8×10 -5 m 3 , K t =9×10 -12 m 3 / s / Pa,A f =100,

[0106] Comparison of simulation results: the controller parameters designed by the present invention are selected as: k=1×10 5 , the adaptive law parameter is chosen as Γ θ =diag[3×10 -17 ,1×10 -14 ,1×10 -7 , 2×10 -7 ,1×10 -8 , 1×10 -15 ],

[0107] Γ ψ =diag[1×10 -8 ,1×10 -8 , 1×10 -8 ,1×10 -10 , 1×10 -10 ].

[0108] The estimation range of the system parameters is selected as:

[0109] θ min =[0.83×10 -11 ,2.63×10 -9 ,2.47×10 -4 , 3.34×10 -8 ,2.63×10 -7 , 0.083×10 -8 ] T ,

[0110] θ max =[03.34×10 -11 ,10.52×10 -9 ,9.9×10 -4 , 13.4×10 -8 ,10.52×10 -7 , 0.334×10 -8 ] T ,

[0111] ψ min =[-10,-50,-50,-50,-50] T , ψ max =[10,50,50,50,50] T .

[0112] The time-varying exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com