Mobile terminal 3D glass cover and production method thereof

A glass cover, mobile terminal technology, applied in instruments, coatings, computing, etc., can solve problems such as poor appearance, white spots, poor edge ink etching, etc., to improve product quality, wide application range, and solve the mass production process. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

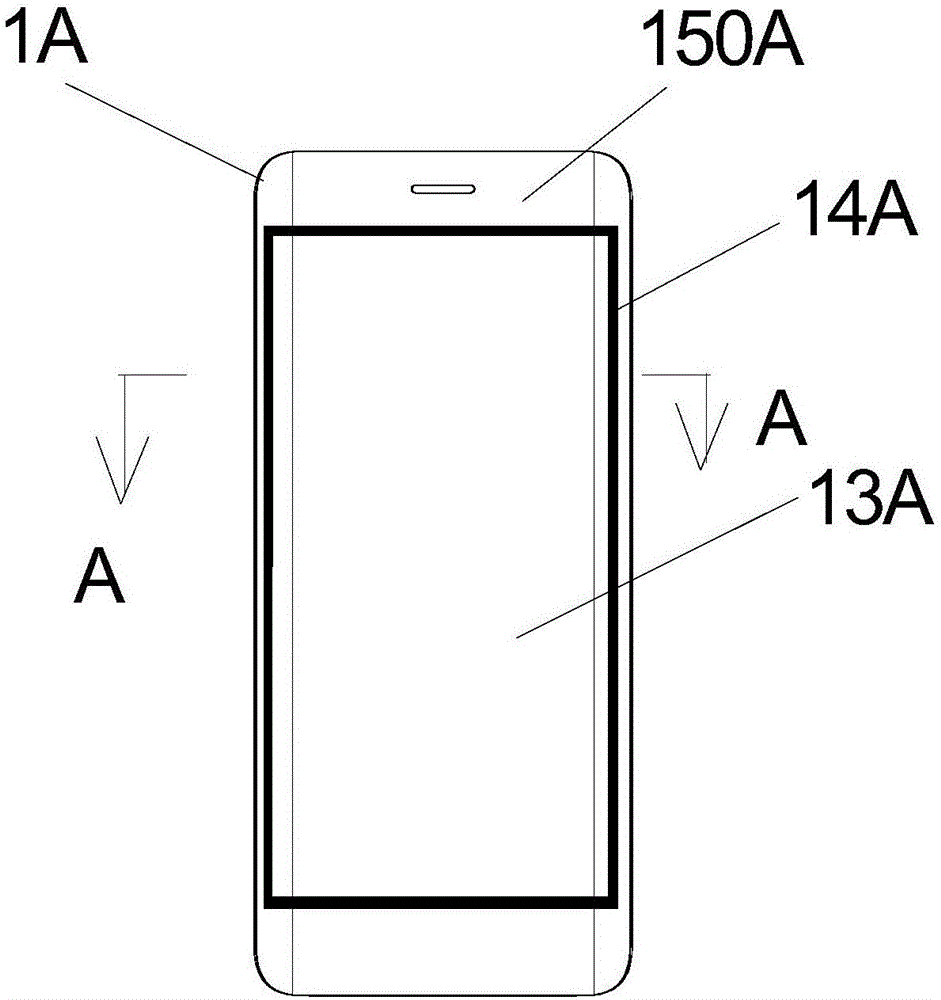

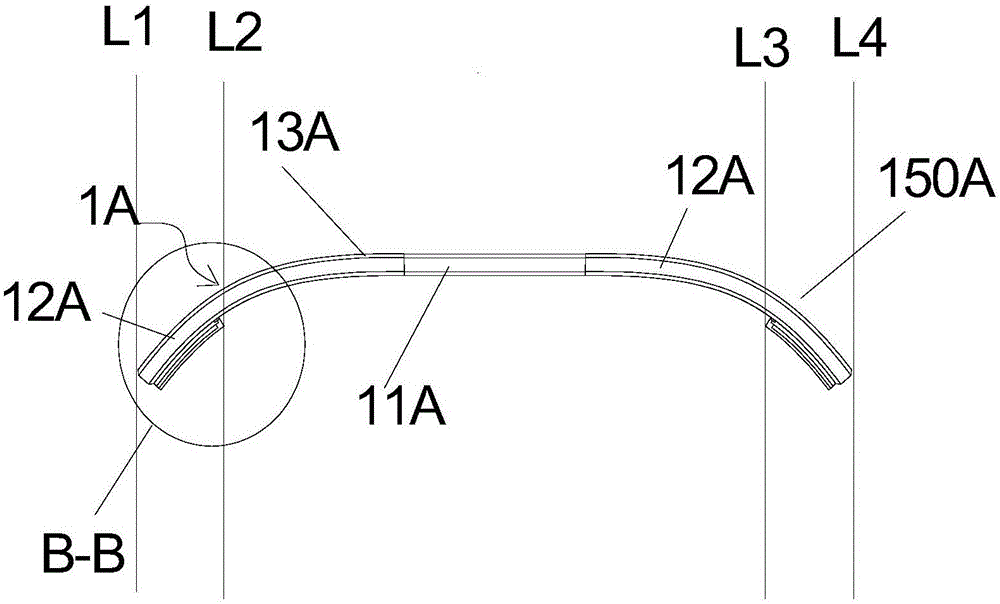

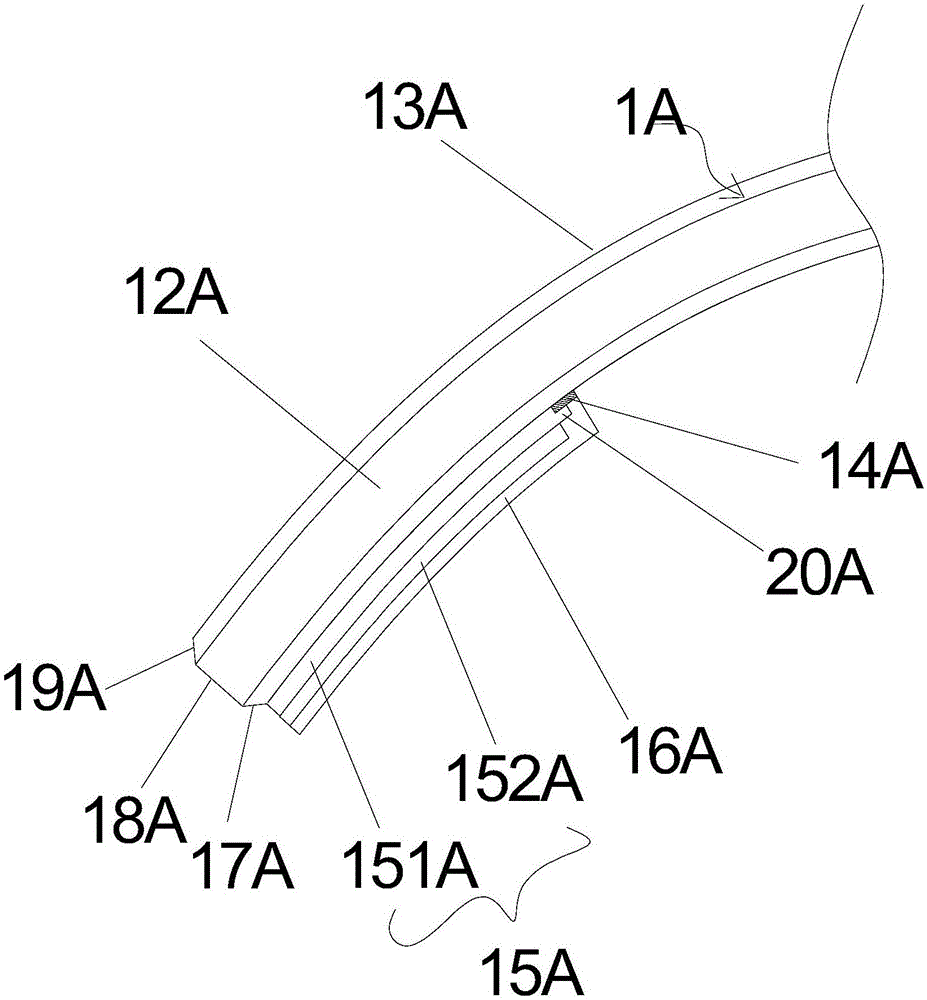

[0034] Such as Figure 5 , Figure 6As shown, a mobile terminal 3D glass cover of the present invention includes a glass cover body 1 and an ink covering part 2 arranged on the bottom surface 15 of the glass cover body 1. The glass cover body 1 includes a middle flat part 11 and The 3D curved part 12 located at the edge, the middle of the ink covering part 2 encloses a transparent visible area 13, the glass cover body 1 includes a top surface 14, a bottom surface 15, and a side surface 16 connecting the top surface 14 and the bottom surface 15, the side surface 16 Including an inner chamfer surface 161, a straight rising surface 162 and an outer chamfer surface 163, the top surface 14 and the bottom surface 15 are connected by the outer chamfer surface 163, the straight rising surface 162 and the inner chamfer surface 161, and it is characterized in that: ink coverage The part 2 includes a common white ink layer 221 , and the normal white ink layer 221 extends to cover the in...

Embodiment 2

[0040] This embodiment is used to manufacture the manufacturing method of the mobile terminal 3D glass cover described in Embodiment 1, which is realized through the following steps: Figure 7 as shown,

[0041] Process 1. Production of the inner ink black frame: Spray a layer of black photosensitive ink on the bottom surface of the 3D glass cover body, then expose to UV light, develop and etch to obtain the inner ink black frame 21;

[0042] Process 2. Production of ordinary white ink layer: On the basis of process 1, spray ordinary white ink on the ink covering part 2 of the bottom surface of the 3D glass cover body, and the ordinary white ink extends to cover the inner chamfer surface 161 and the straight-up surface 162, then dry to form a common white ink layer 221;

[0043] Process 3, photosensitive white ink layer: on the basis of process 2, spray white photosensitive ink on the bottom surface of the 3D glass cover body, then expose to UV light, develop and etch to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com