Surface of guiding printed substrate with micro-protuberance

A technology of substrates and micro-protrusions, applied in printing, printing plates, printing foils, etc., to achieve the effect of improving the quality of printed images, realizing the quality of printed images, and improving the quality of printed images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

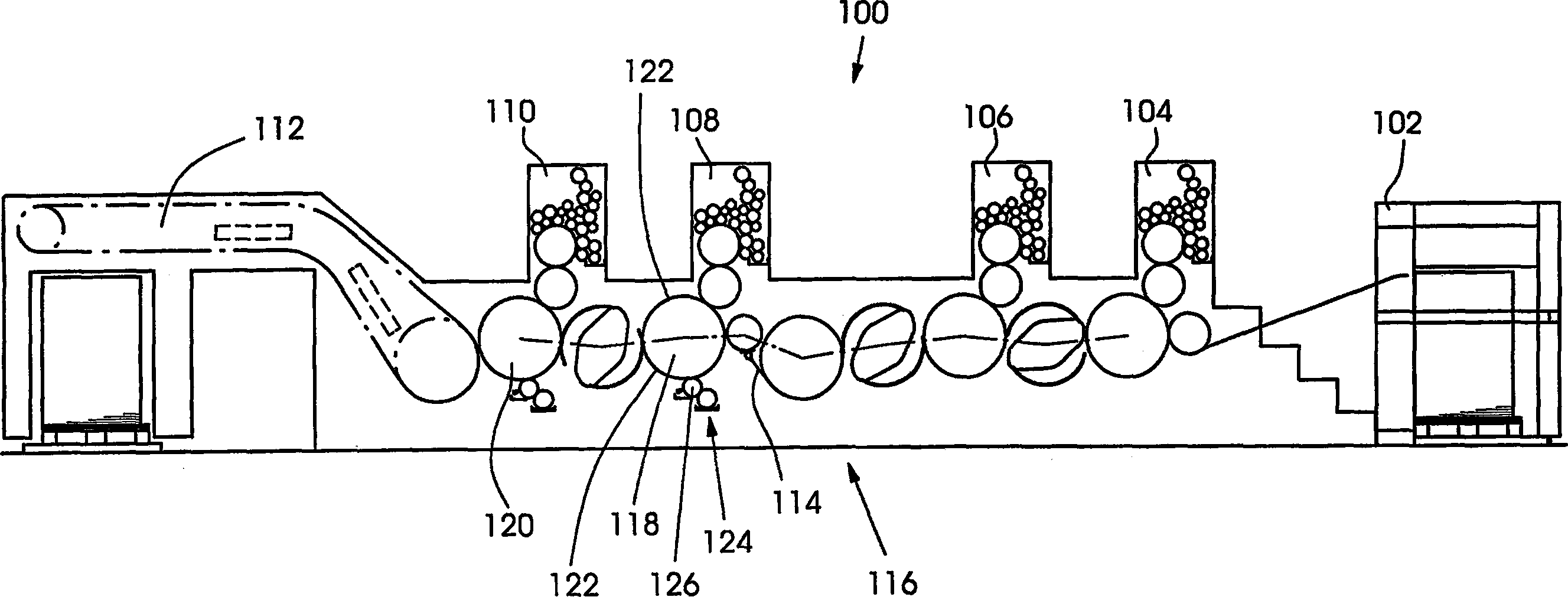

[0038] figure 1 A sheetfed offset printing press 100 is shown with a sheet feeder 102 , four offset printing units 104 , 106 , 108 and 110 and a sheet delivery 112 . The printing press 100 can be operated in a duplex printing mode, ie two first printing units 104 and 106 print the first side of a substrate sheet 114 and the other two printing units 108 and 110 print the second side of the substrate 114 Second side. For this purpose, the printing material 114 is turned over by a turning device 16 .

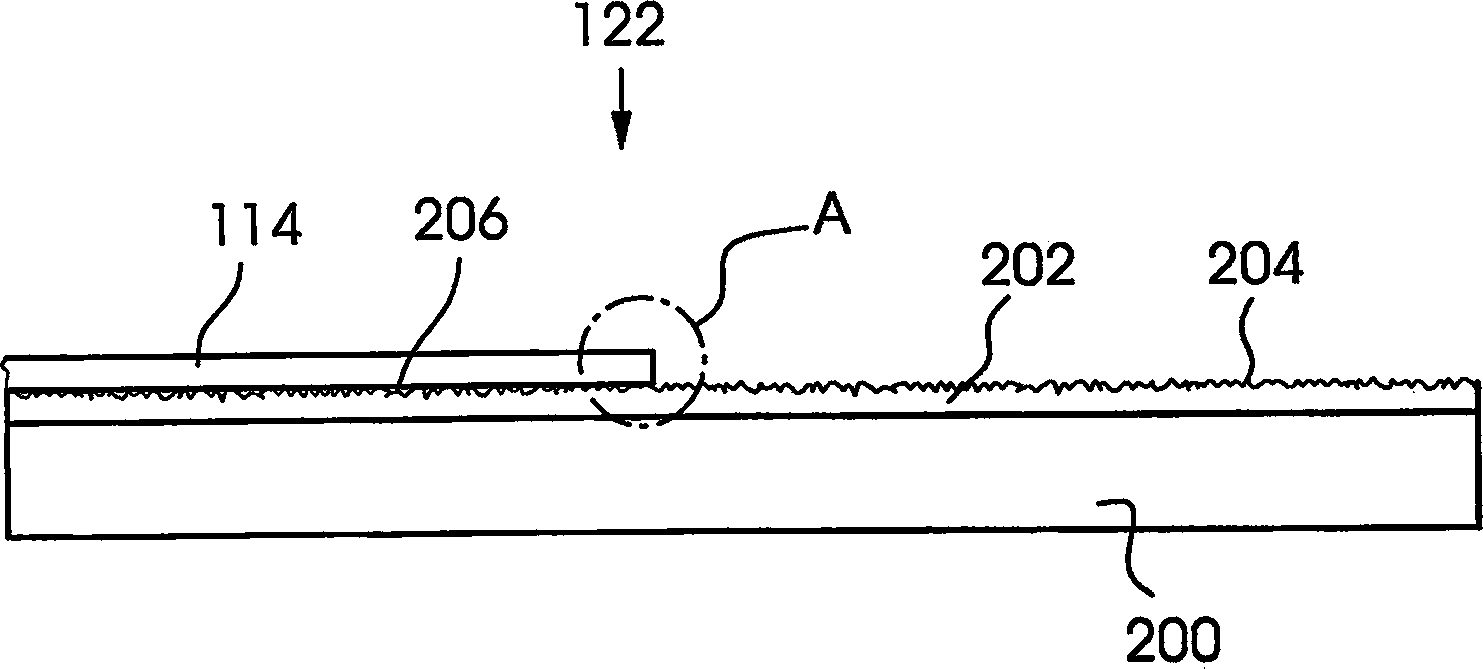

[0039] The printing material 114 rests with the printed first side against the two impression cylinders 118 and 120 arranged downstream of the inversion device 116 and passes through the corresponding printing gaps of the printing devices 108 and 110 under pressing force. In order to prevent ink from falling off and accumulating on the respective substrate-guiding surfaces of the impression cylinders 118 and 120 and to prevent relative movement between the substrate 114 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com