Noodle making method of a noodle machine and noodle machine thereof

A pasta machine and main machine technology, applied in the direction of dough extruder, dough mixer, mixing/kneading machine structural components, etc., can solve the problems of dough mixing failure and affecting user experience, etc., to achieve accurate noodle making success rate, Delay service life, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

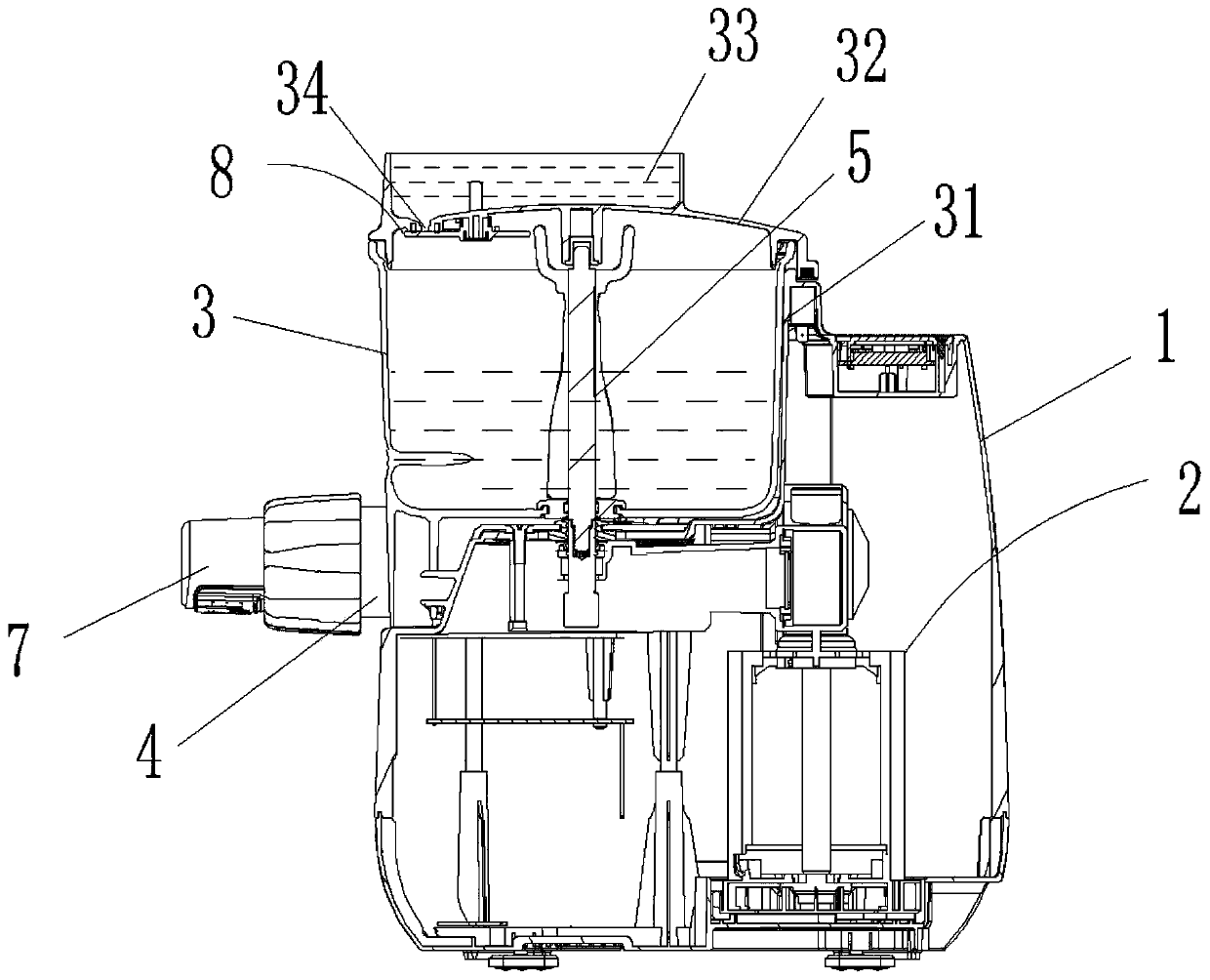

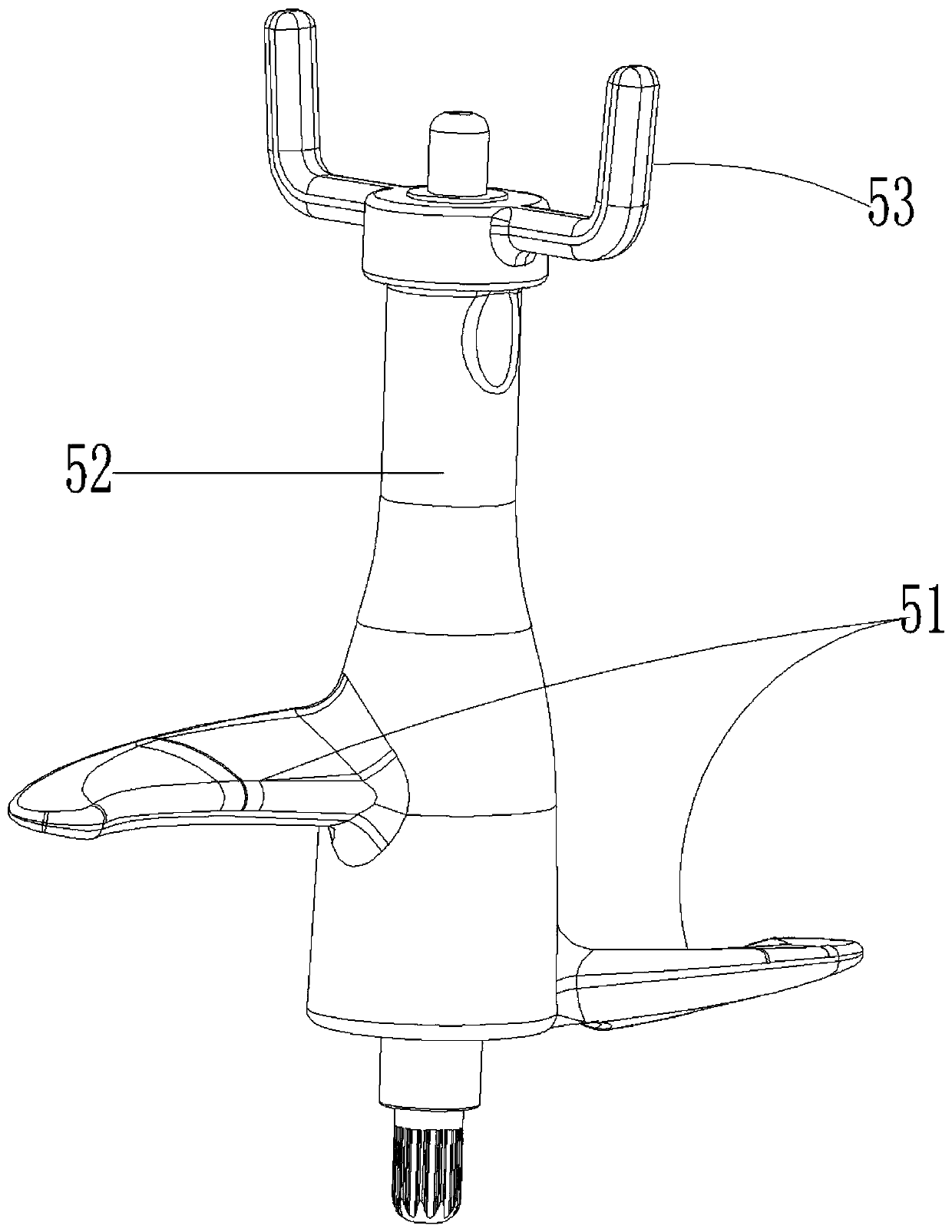

[0033] Such as figure 1 Shown, a kind of pasta machine with reservation function, the pasta machine is household noodle machine in the present embodiment. Comprise main frame 1, be arranged on the motor 2 in the main frame 1 and control panel (not shown in the figure), be arranged on main frame 1 stirring cup 3 and extruding cylinder 4, the pasta machine is a vertical pasta machine in the present embodiment, extruding The noodle cylinder 4 is arranged on the side below the stirring cup 3, and communicates with the noodle inlet at the bottom of the stirring cup 3. The stirring cup 3 is provided with a stirring rod 5, and the stirring rod 5 is vertically arranged in the stirring cup 3. The stirring rod 5 comprises the stirring tooth 51 that is positioned at wherein lower section, is upper and lower stirring tooth 51 in the present embodiment, is provided with screw rod (not shown in the figure) in the extruding cylinder 4, and the end of extruding cylinder 4 is provided with die...

Embodiment 2

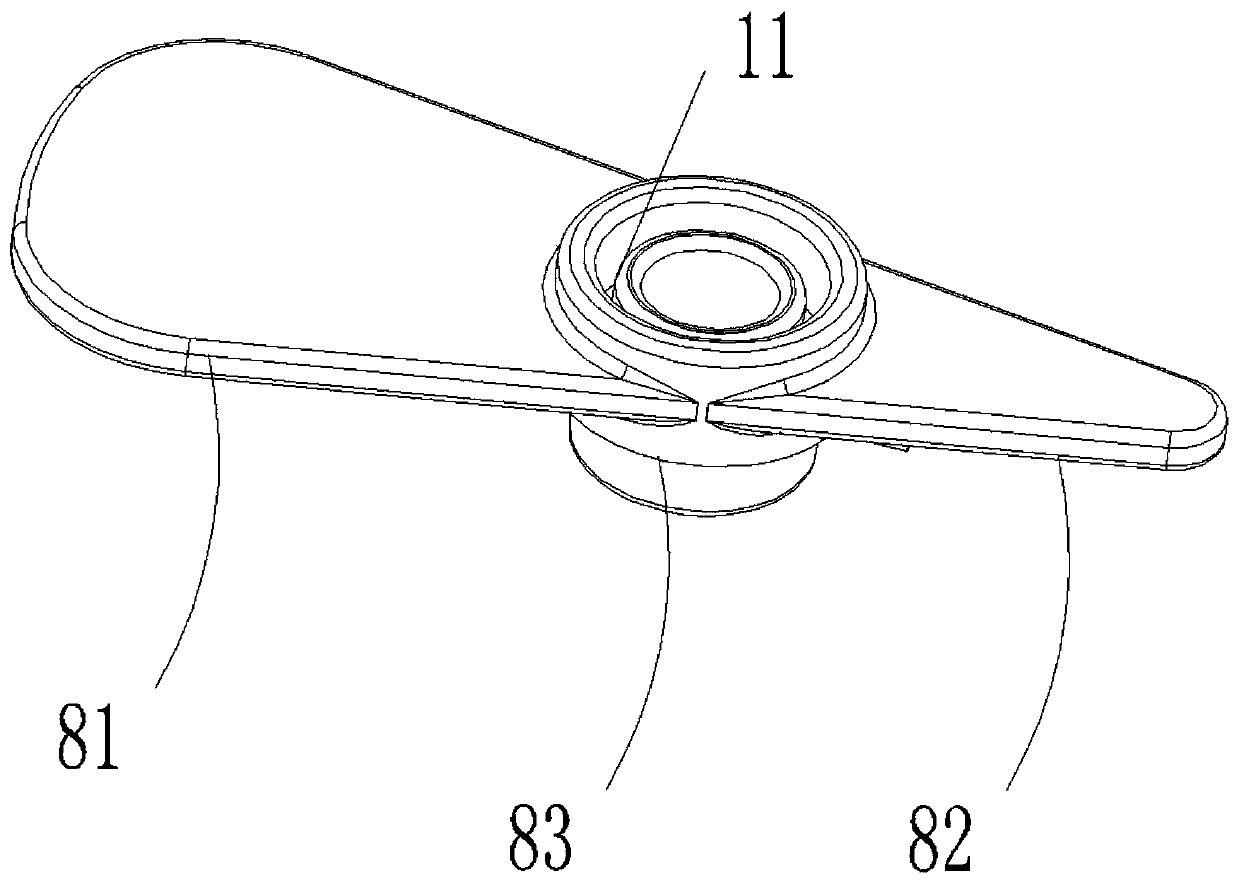

[0054] The difference between this embodiment and Embodiment 1 is that the setting position of the baffle 8 is different. Teeth 53, the driving teeth 53 drive the blocking plate 8 to rotate; or, the blocking plate 8 is located above the water injection hole 34, and the upper cover 32 is provided with a driving assembly that rotates in conjunction with the stirring rod 5 , the rotation of the stirring rod 5 drives the driving assembly to rotate, and the driving assembly includes a driving tooth 53, and the driving tooth 53 drives the blocking plate 8 to rotate. The advantage of this setting is that the upper end of the water injection hole 34 is sealed by the baffle 8, so that the entire driving structure is above the cup cover and not in the stirring cup 3, so there is no conflict with the original mixing step of the dough mixing stage, avoiding The interference during the stirring process makes the steps of opening and closing the water injection hole 34 and the step of stirr...

Embodiment 3

[0056] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the pasta machine in this embodiment is a horizontal pasta machine, the stirring rod 5 and the screw are coaxial and arranged laterally, and the structure of the horizontal pasta machine is a general structure, not in Described in detail, the stirring rod 5 includes stirring teeth 51 arranged on the rod body 52 , and during the rotation of the stirring rod 5 , the stirring teeth 51 drive the baffle 8 to rotate so as to open the water injection hole 34 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com