Intelligent bread maker

A bread machine, intelligent technology, applied in toasting devices, household appliances, applications, etc., can solve the problems of splashing out of the inner barrel, large impact, flour and water splashing, etc., to achieve low cost, ensure taste, and enhance value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

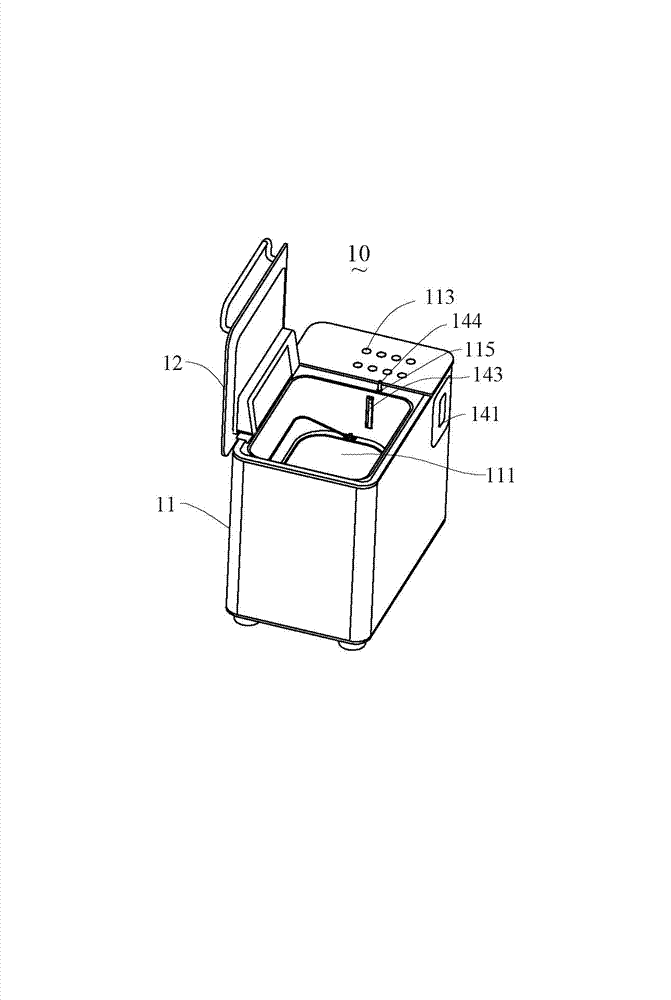

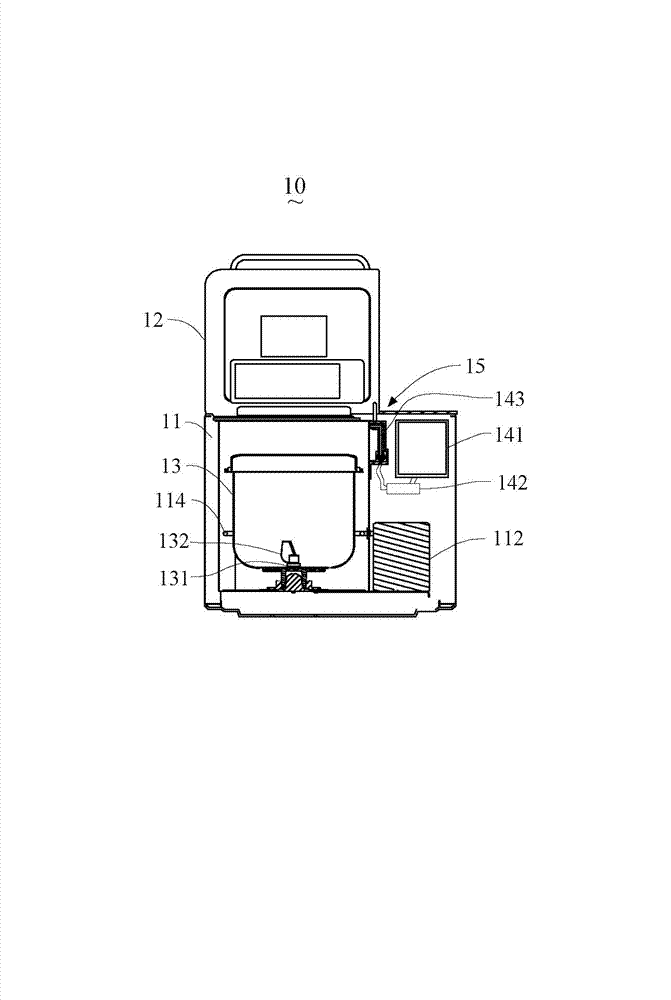

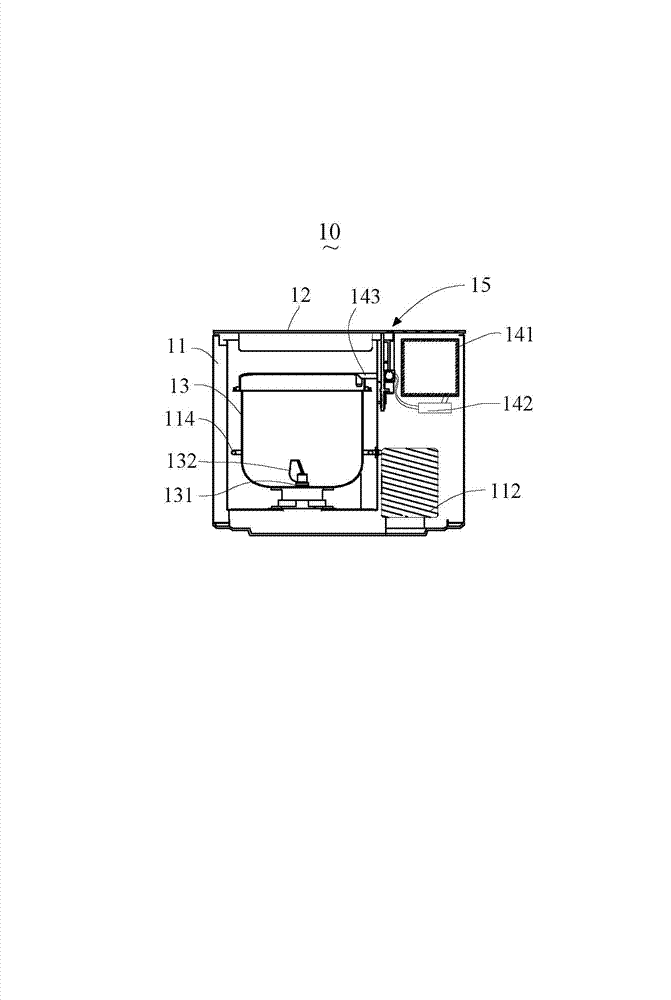

[0045] Please also refer to figure 1 , figure 2 , image 3 , Figure 4 As shown in the first embodiment of the intelligent bread machine of the present invention, the intelligent bread machine 10 includes a body 11, an upper cover 12 and an inner barrel 13, the inner barrel 13 is placed in the body 11, and the body 11 is provided with water into the inner barrel 12. Water adding device 14, water adding device 14 includes water tank 141 and water pump 142, water adding rod 143 and push rod 144, water adding rod 143 is hinged on the body 11 through rotating shaft 145, push rod 144 can touch water adding rod 143 to rotate to the top of inner bucket 13, the upper cover 12 is provided with the touch portion 121 that touches the push rod 144 to move downward when the lid is closed, and the push rod 144 and the water-filling rod 143 are mechanically connected by a motion conversion mechanism 15, which converts the movement of the push rod 144 into water filling. With the rotation...

Embodiment approach 2

[0060] see Figure 5 Shown is the second embodiment of the smart bread machine of the present invention, the difference between the smart bread machine 20 and the smart bread machine 10 is that the smart bread machine 20 also includes a micro switch 21 for detecting the opening and closing of the upper cover 12, and the micro switch 21 The manual switch 21 is electrically connected to the control board 113.

[0061] When the upper cover 12 seals the cavity 111, the push rod 144 triggers the microswitch 21, and the control board 113 starts the water pump 142 to supply water after receiving the signal from the microswitch 21. When the upper cover 12 opens the cavity 111, the push rod 144 resets, and the micro switch 21 also resets. After the control board 113 receives the signal of the micro switch 21, the water pump 142 is prohibited from working. In this way, by setting the micro switch 21, the risk of water supply by the water pump 142 when the upper cover 12 is opened is av...

Embodiment approach 3

[0066] Please also refer to Image 6 , Figure 7 Shown is the third embodiment of the smart bread maker of the present invention, the difference between the smart bread maker 30 and the smart bread maker 20 is that the motion conversion mechanism includes a turning handle 31 that pushes the water adding rod 143 to rotate, and the water adding rod 143 is sleeved On the rotating shaft 145 , the rotating handle 31 is fixedly connected with the water adding rod 143 , and the push rod 144 is provided with a sliding part 32 for pushing the rotating handle 31 . The sliding portion 32 abuts against the rotating handle 31 , and the reset member 16 is a reset torsion spring sheathed on the rotating shaft 145 .

[0067] The rotating handle 31 is fixedly connected with the water adding rod 143 , and the water adding rod 143 is sheathed on the rotating shaft 145 , so that the rotating handle 31 and the water adding rod 143 can rotate around the rotating shaft 145 .

[0068] One end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com